Method for preparing efficient polycarboxylate graft copolymer super plasticizer through microwave-assisting method

A graft copolymer and microwave-assisted technology is applied in the field of preparing polycarboxylate graft copolymer high-efficiency superplasticizers, which can solve the problems of poor dispersion retention ability and wide molecular weight distribution, and achieve excellent slump retention and slow release. performance, low dispersion index, superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

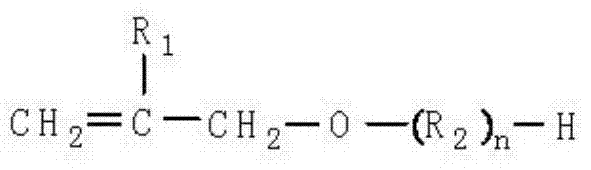

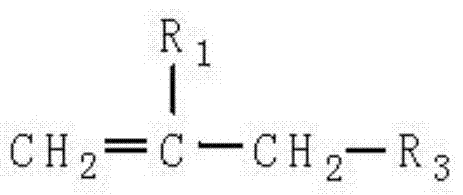

[0048] 0.7mol methallyl polyoxyethylene ether (n=26), 0.3mol methoxypolyethylene glycol methacrylate (m=17), 0.05mol sodium methacrylate, 0.01mol vinyl acetate Ester, 3.5mol acrylic acid, 0.2mol sodium styrene sulfonate, 21mol water and 10.8g ammonium persulfate were added to the focused microwave reaction vessel at one time, and the temperature was 35°C, and the microwave radiation power was 110W. After copolymerization for 12 minutes, water was replenished. Adjust the concentration of the solution to 40%, and at the same time use 30% sodium hydroxide to neutralize to Ph=7, replenish water to adjust the concentration of the solution to 40%, and obtain the polyacrylic acid grafted polycarboxylic acid high-efficiency superplasticizer product PC -1, its polymerization dispersion index is 3.5.

Embodiment 2

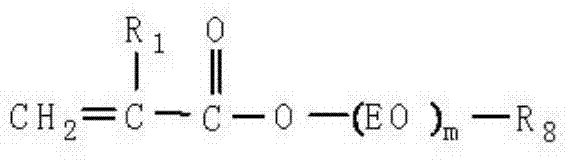

[0050] Add 1 mol of methallyl polyoxyethylene ether (n=53) and 9.8 mol of water into a focusing microwave reaction vessel and stir evenly, heat up to 40°C, and after the microwave radiation power rises to 170W, add 0.02 mol of methallyl Sulfonic acid, 0.02mol vinyl propionate, 3.0mol acrylic acid, 0.1mol hydroxyethyl acrylate and 4.9mol water are configured into an aqueous solution; 8.4g potassium persulfate and 2.4mol water are configured into an aqueous solution, and the speed is controlled to focus on the microwave reaction vessel The monomer mixed solution and the initiator solution were added dropwise in the mixture, and the dropping time was 10 minutes. After the dropping was completed, the constant temperature was reacted for 10 minutes, and the water was replenished and neutralized to Ph=7 with a mass fraction of 40% triethanolamine to obtain a polyacrylic acid grafted polymer. Carboxylic acid high-efficiency superplasticizer product PC-2 has a polymerization dispersion...

Embodiment 3

[0052] Add 1 mol of methoxypolyethylene glycol methacrylate (m=54) and 10.8 mol of water into a focusing microwave reaction vessel, raise the temperature to 25°C, and after the microwave radiation power rises to 150W, add 11.2 g and 3.7 mol of water The prepared ammonium persulfate solution was added to the container once, and 0.01mol of allylsulfonic acid, 0.01mol of isopropenyl acetate and 5.4mol of water were prepared into an aqueous solution, which was the monomer b solution; 2.8mol of acrylic acid, 0.7mol of propylene Amide, 0.21mol hydroxybutyl acrylate, 0.14mol sodium styrene sulfonate and 5.4mol water are configured into an aqueous solution, which is the solution of monomer c. The dripping time of solution b is 7 minutes, and the dripping time of monomer c solution is 15 minutes. After the dripping is completed, the constant temperature reaction is carried out for 10 minutes, and the water is replenished and neutralized to Ph=7 with a mass fraction of 40% diethanolamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com