Alkaline welding flux cored wire protected by CO2 gas or 80Ar + CO2 gas

A technology of gas shielding and welding wire, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of low low-temperature impact toughness value of weld metal, fracture or damage of welding place, unclean purification of weld seam, etc. , achieve the effect of high and low temperature impact toughness, less welding fume and less welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

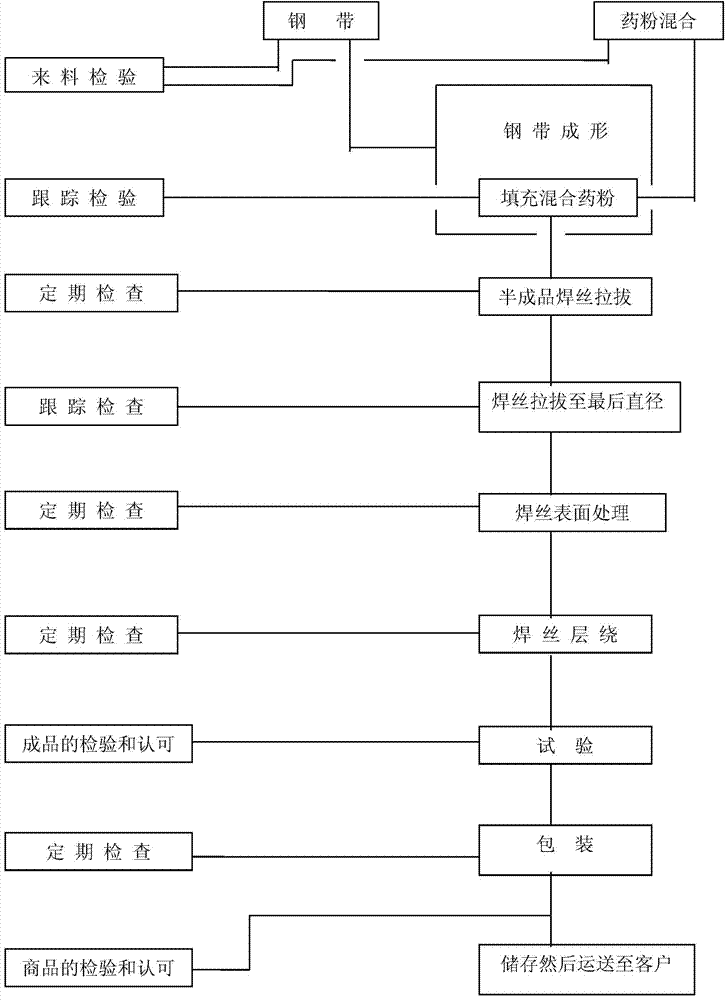

Method used

Image

Examples

Embodiment 1

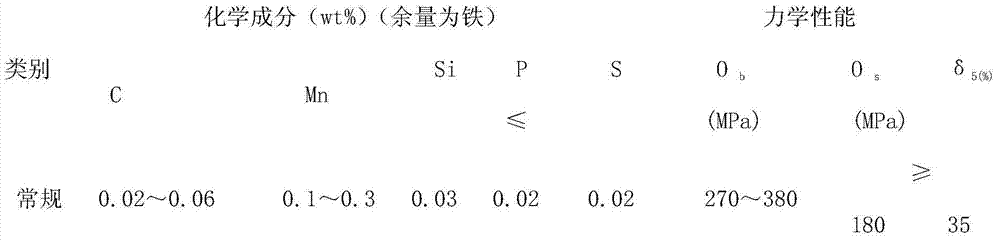

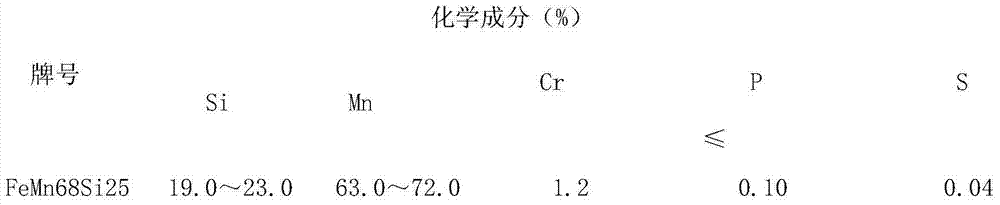

[0063] Select a steel strip with a nominal thickness of 0.80mm, cut the nominal width into a cold-rolled steel strip for flux-cored welding wire with a nominal width of 14mm, and roll it into a U-shaped groove by a forming machine. Take 100 parts of medicine core powder as an example: take 17 parts of rutile, 23 parts of silicon manganese, 35 parts of iron powder, 9 parts of nickel powder, 3 parts of aluminum magnesium, 3.5 parts of marble, 3.5 parts of fluorite, and 6 parts of ferrovanadium. Put all the raw materials into the mixer and mix for 45 minutes, then add them to the U-shaped channel steel belt, the filling rate is 17%; close the U-shaped channel so that the drug core powder is wrapped in it, and then draw and reduce the diameter through the wire drawing machine , finally making the diameter of the wire reach 1.2mm.

[0064] Sample experiment:

[0065] 1. Deposited metal specimen

[0066] For each test piece of deposited metal test, two test plates and one gasket s...

Embodiment 2

[0082] Select a steel strip with a nominal thickness of 0.80mm, cut the nominal width into a cold-rolled steel strip for flux-cored welding wire with a nominal width of 14mm, and roll it into a U-shaped groove by a forming machine. Take 100 parts of flux-cored wire as an example: take 13 parts of rutile, 30 parts of silicon manganese, 25 parts of iron powder, 8 parts of nickel powder, 6 parts of aluminum magnesium, 2 parts of marble, 2 parts of fluorite, and 14 parts of ferrovanadium. Put all the raw materials into the mixer and mix for 45 minutes, then add them into the U-shaped groove made by steel strip rolling, and the filling rate is 17%; close the U-shaped groove so that the drug core powder is wrapped in it, and then pull through the wire drawing machine Pulling out and reducing the diameter finally makes the diameter of the welding wire reach 1.2mm.

Embodiment 3

[0084] Select a steel strip with a nominal thickness of 0.80mm, cut the nominal width into a cold-rolled steel strip for flux-cored welding wire with a nominal width of 14mm, and roll it into a U-shaped groove by a forming machine. Take 100 parts of flux-cored wire as an example: take 24% rutile, 26 parts silico-manganese, 25 parts iron powder, 5 parts nickel powder, 5 parts aluminum-magnesium, 5 parts marble, 5 parts fluorite, and 5 parts ferrovanadium. Put all the raw materials into the mixer and mix for 45 minutes, then add them to the U-shaped channel steel belt, the filling rate is 17%; close the U-shaped channel so that the drug core powder is wrapped in it, and then draw and reduce the diameter through the wire drawing machine , finally making the diameter of the wire reach 1.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com