Method for preparing chemicals containing phenols and aromatic hydrocarbons from bio-oil pyrolysis lignin through catalysis

A kind of aromatic hydrocarbons, catalytic preparation technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process and other directions, can solve the problems of bio-oil pyrolysis lignin processing and utilization without efficient and mature and stable technical means, to achieve added value of products High, improve energy value, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

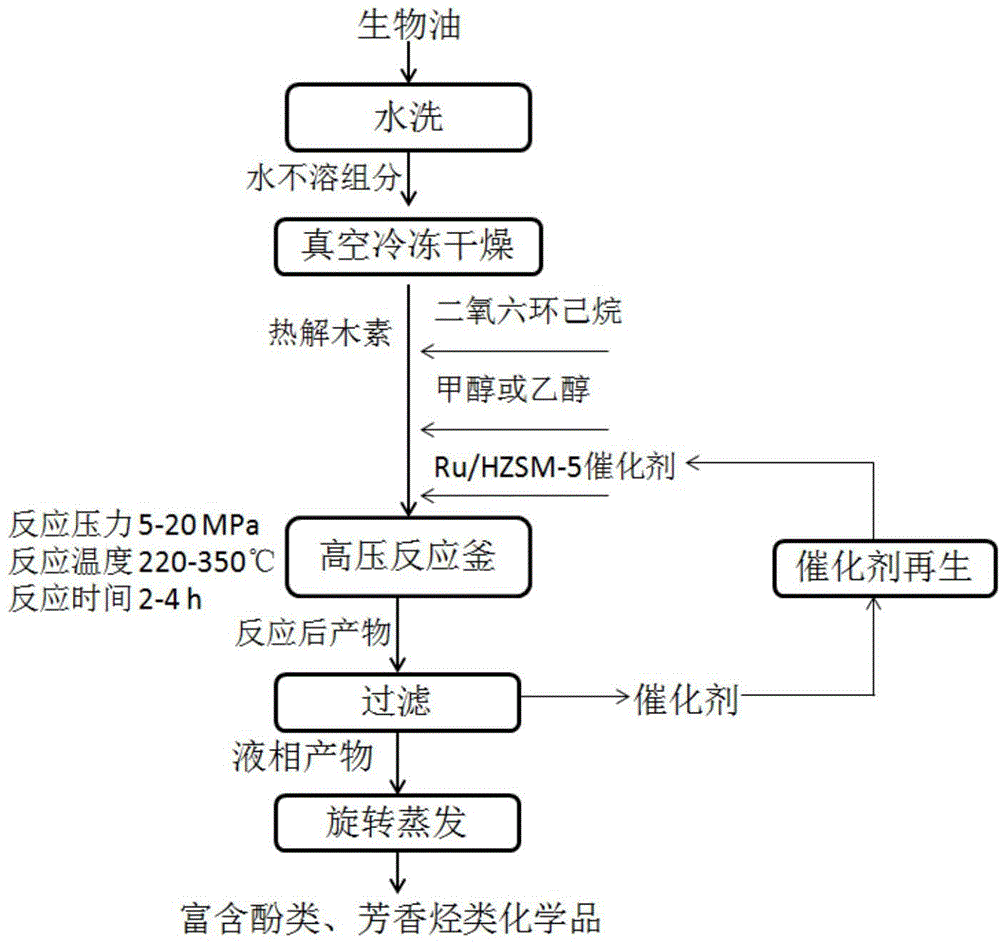

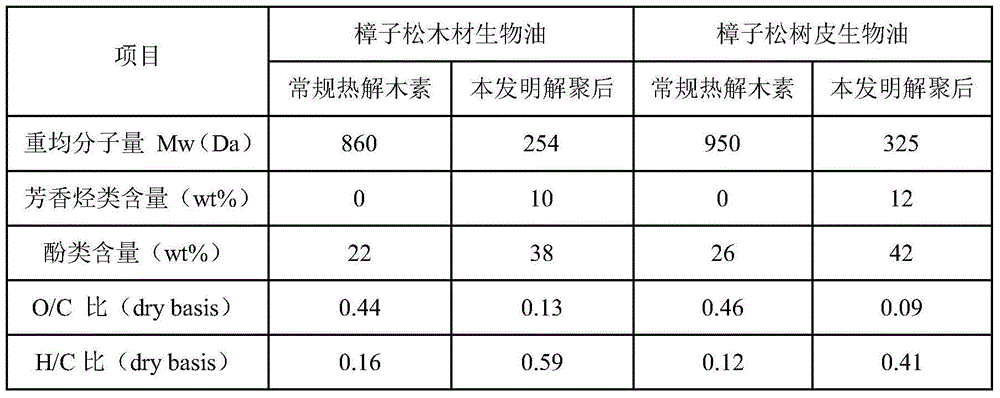

[0023] Taking the bio-oil obtained by fast pyrolysis of Pinus sylvestris as an example, the implementation process of the present invention is introduced as follows:

[0024] (1) Take 100g of bio-oil, add 500g of distilled water slowly, stir and filter to obtain 35g of water-insoluble matter; freeze the water-insoluble matter at -60°C under 10Pa vacuum condition for 8 hours, and obtain 15g of solid pyrolytic lignin after drying;

[0025] (2) Dissolve the obtained solid pyrolytic lignin in 25g of dioxane with a mass percentage of 85%, then add 40g of methanol, add 5g of Ru / HZSM-5 catalyst, mix well, and move it into a high-pressure reactor;

[0026] (3) Use hydrogen to replace the air in the reactor twice, and then fill it with 2MPa hydrogen to maintain a reducing atmosphere, start the hydrocracking reaction, the reaction pressure is 5MPa, the reaction temperature is 250°C, and the depolymerization reaction is maintained for 2.5h;

[0027] (4) Filter the above reaction mixture,...

Embodiment 2

[0030] Taking the bio-oil obtained by fast pyrolysis of Pinus sylvestris pine bark as an example, the implementation process of the present invention is introduced as follows:

[0031] (1) Take 100g of bio-oil, slowly add 500g of distilled water, stir and filter to obtain 42g of water-insoluble matter; freeze the water-insoluble matter at -40°C for 12 hours under vacuum conditions of 15Pa, and obtain 21g of solid pyrolytic lignin after drying;

[0032] (2) Dissolve the obtained solid pyrolytic lignin in 40g of dioxane with a mass percentage of 96%, then add 50g of ethanol, add 7g of Ru / HZSM-5 catalyst, mix well, and move it into a high-pressure reactor;

[0033] (3) Use hydrogen to replace the air in the reactor twice, and then fill it with 3MPa hydrogen to maintain a reducing atmosphere, start the hydrocracking reaction, the reaction pressure is 15MPa, the reaction temperature is 350°C, and the depolymerization reaction is maintained for 3h;

[0034] (4) Filter the above reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com