High-flowability polyamide based halogen-free flame-retardant heat-conducting composite material and preparation method thereof

A fluid polyamide-based, heat-conducting composite material technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of affecting the processing performance of materials and product appearance, the thermal conductivity of composite materials can not meet the requirements, composite materials Solve the problems of poor melt fluidity and achieve the effect of excellent melt fluidity, low flame propagation and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention are clearly and completely described below. Obviously, the embodiments of the present invention include but are not limited to the described embodiments. Based on this, all other embodiments obtained by those skilled in the art without innovative work fall within the protection scope of the present invention.

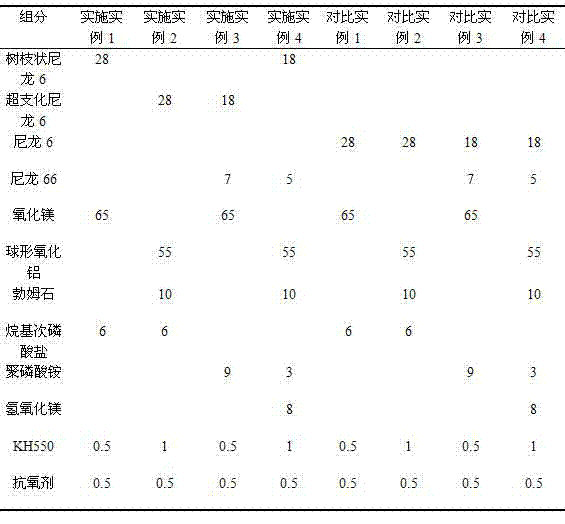

[0034] Resin adopted in the embodiment of the invention is dendritic nylon or hyperbranched nylon, and what adopted in the comparative example is conventional nylon, the embodiment of the present invention and comparative example see the following table 1:

[0035] Table 1 Implementation Example and Comparative Example Material Formula Table

[0036]

[0037] Among them, at the shear temperature of 230 oC , the shear strength is 500s -1 Under the test conditions, the relative viscosity of dendritic high-fluidity nylon 6 is 1.6; the relative viscosity of hyperbranched high-fluidity nylon 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com