Preparation method of copper oxide nanowires and application of copper oxide nanowires in negative electrode of lithium ion battery

A technology of copper oxide nanowires and copper oxide, applied in copper oxide/copper hydroxide, battery electrodes, nanotechnology, etc., can solve the problems of low operability, complicated production process, and difficult industrialization, and achieve simple and easy process flow Lines, good rate performance, easy effect on diameter and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First, soak the copper foil (99.99% pure, 1mm thick) in 1mol / L dilute hydrochloric acid solution for 4 hours to remove surface oxides and impurities. Rinse repeatedly with deionized water until the washing solution is neutral. Then the dried copper foil was put into a muffle furnace, air was continuously introduced, and the temperature was raised to 600°C at a heating rate of 3°C / min, and the holding time was 3, 6, 9, and 12 hours respectively.

[0019] Weigh 0.055g of copper oxide nanowires, 0.03g of acetylene black, and 0.015g of binder according to a mass ratio of 55:30:15. After mixing evenly, the electrode material is prepared.

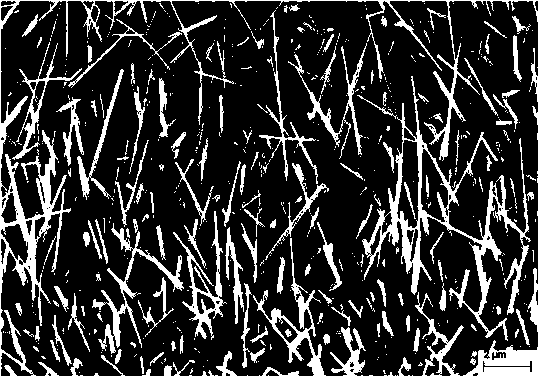

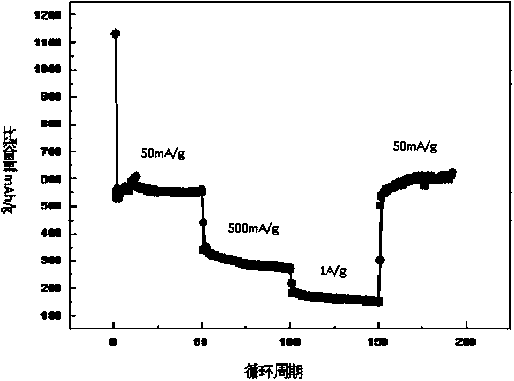

[0020] as attached figure 1 As shown by the scanning electron microscope, the basic morphology of the copper oxide nanowires generated by thermal oxidation is to grow perpendicular to the copper base, forming a one-dimensional nanowire with a thick bottom and a sharp top. The diameter is 100-130nm and the length is 26-30μm. as attached...

example 2

[0022] The preparation method of copper oxide nanowires is the same as Example 1, except that the dried copper foil is put into a muffle furnace, air is continuously introduced, and the temperature is raised to 500° C. at a heating rate of 3° C. / min, and the holding time is 3, 6, 9, 12 hours.

[0023] The obtained nanowires have a length of 22-26 μm and a diameter of 130-170 nm. The electrochemical performance test results show that when the current density is 50mA / g, the specific capacities are 175mAh / g, 298mAh / g, 314mAh / g, and 310mAh / g at different oxidation times.

example 3

[0025] The preparation method of copper oxide nanowires is the same as Example 1, except that the dried copper foil is put into a muffle furnace, air is continuously introduced, and the temperature is raised to 400° C. at a heating rate of 3° C. / min, and the holding time is 3, 6, 9, 12 hours.

[0026] The obtained nanowires have a length of 15-22 μm and a diameter of 170-200 nm, respectively. The electrochemical performance test results show that when the current density is 50mA / g, the specific capacities are 124mAh / g, 275mAh / g, 309mAh / g, and 252mAh / g at different oxidation times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com