Lithium ion battery, anode material and preparation method of anode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficult to achieve stoichiometric ratio, adverse effects of batteries, uneven NiMn ratio, etc., to achieve inhibition of Co dissolution and excellent cycle Performance, the effect of protecting the structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

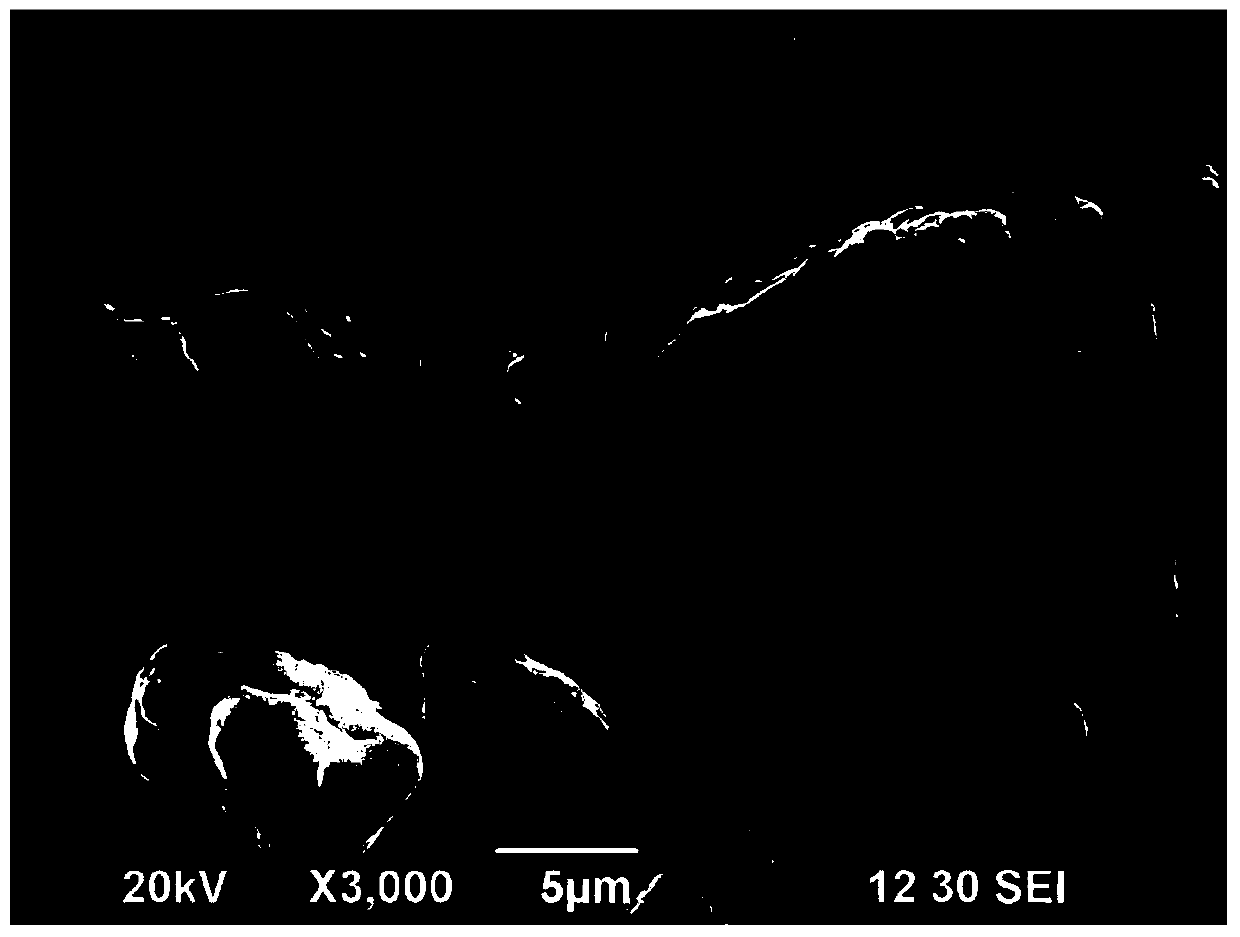

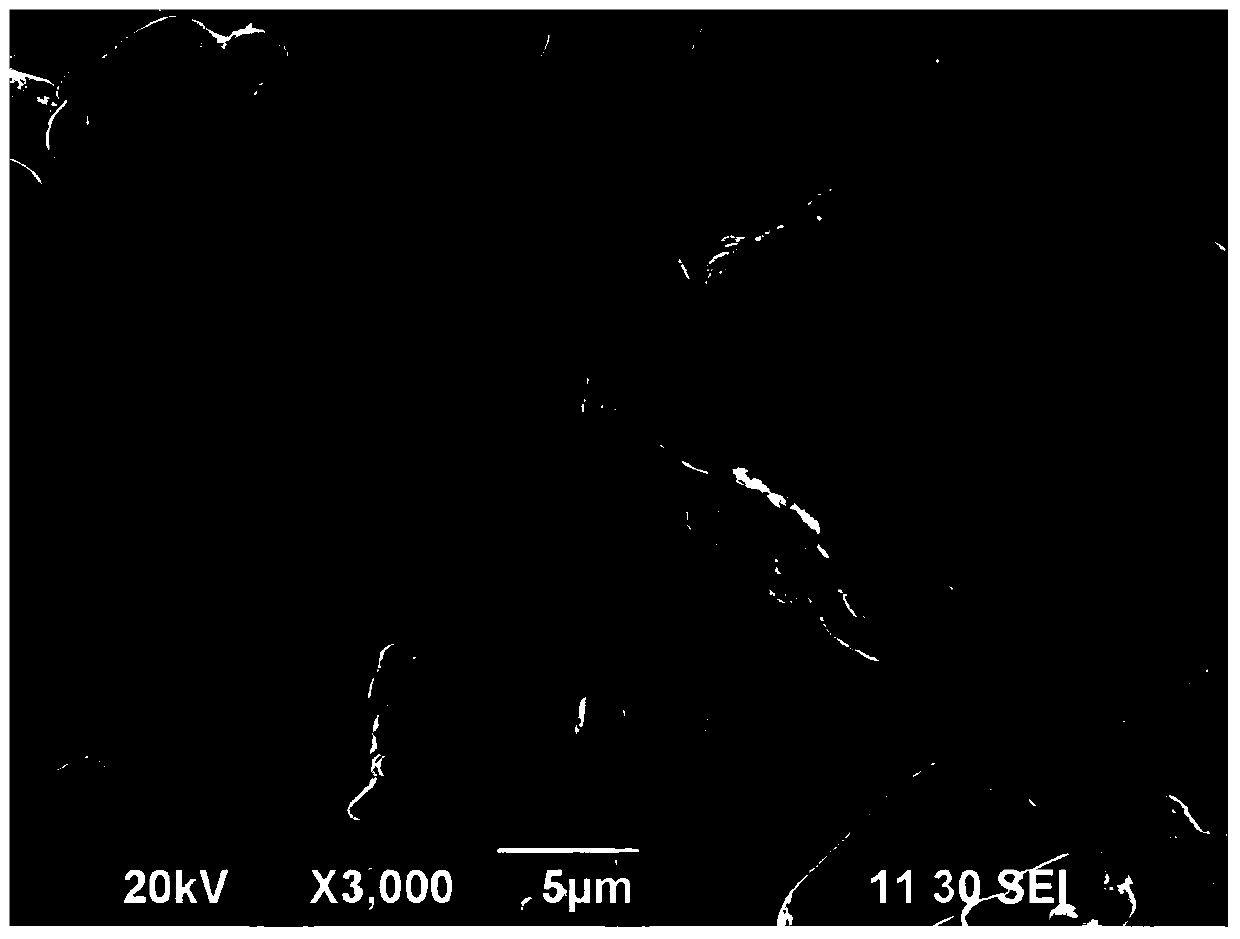

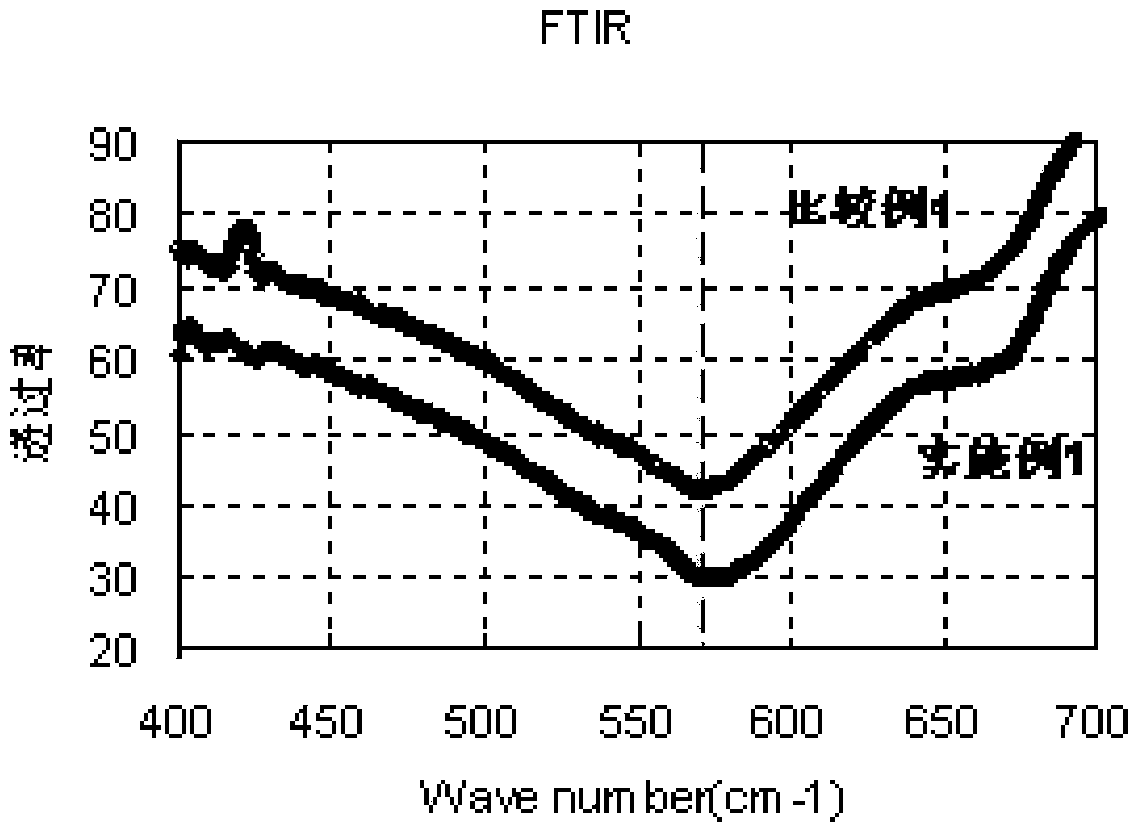

[0049] This example is 0.96LiCoO 2 0.02LiNi 0.4 mn 0.4 Mg 0.2 o 2 0.02LiNi 0.45 mn 1.45 Al 0.1 o 4 A cathode material for lithium-ion batteries with a symbiotic structure, the BET of the cathode material is 0.26m 2 / g,D 50 =15μm, D of small particles fused on the surface 50 = 1 μm.

[0050] The preparation steps of above-mentioned cathode material are:

[0051] 1) According to the chemical dosage ratio Ni:Mn:Mg=0.4:0.4:0.2, a certain mass of nickel acetate, manganese acetate and magnesium nitrate are dissolved in water to form the first mixed solution; citric acid is dissolved in water, and lemon The acid solution is added to the first mixed solution to obtain a second mixed solution; the pH of the second mixed solution is adjusted to be 8;

[0052] 2) A certain quality of Co 3 o 4Added to the second mixed solution, stirred and mixed, evaporated to dryness, and roasted at 700°C for 10h in an air atmosphere to obtain (1-x)Co 3 o 4 x(Ni 0.4 mn 0.4 Mg 0.2 o 2 ...

Embodiment 2

[0057] This example is 0.90LiCoO 2 0.09LiNi 0.45 mn 0.45 La 0.1 o 2 0.01LiNi 0.48 mn 1.4 Mg 0.12 o 4 A cathode material for lithium-ion batteries with a symbiotic structure, the BET of the cathode material is 0.18m 2 / g,D 50 =22μm, D of small particles fused on the surface 50 =0.02μm.

[0058] The preparation steps of above-mentioned cathode material are:

[0059] 1) According to the chemical dosage ratio Ni:Mn:La=0.45:0.45:0.1, a certain mass of nickel nitrate, manganese acetate and lanthanum nitrate are dissolved in isopropanol to form the first mixed solution; gluconic acid is dissolved in water, And adding the gluconic acid solution into the first mixed solution to obtain the second mixed solution; adjusting the pH of the second mixed solution to be 6;

[0060] 2) A certain quality of Co 3 o 4 Added to the second mixed solution, stirred and mixed, evaporated to dryness, and roasted at 400°C for 2h in an air atmosphere to obtain (1-x)Co 3 o 4 x(Ni 0.45 mn ...

Embodiment 3

[0065] This example is 0.9LiCoO 2 0.01LiNi 0.45 mn 0.45 Al 0.05 Sr 0.05 o 2 0.09LiNi 0.4 mn 1.4 Ti 0.2 o 4 A cathode material for lithium-ion batteries with a symbiotic structure, the BET of the cathode material is 0.60m 2 / g,D 50 =7μm, D of small particles fused on the surface 50 =0.1 μm.

[0066] The preparation steps of above-mentioned cathode material are:

[0067] 1) According to the chemical dosage ratio Ni:Mn:Al:Sr=0.45:0.45:0.05:0.05, a certain mass of nickel nitrate, manganese nitrate, aluminum isopropoxide and strontium nitrate are dissolved in isopropanol to form the first mixture solution; citric acid was dissolved in water, and the citric acid solution was added to the first mixed solution to obtain a second mixed solution; the pH of the second mixed solution was adjusted to be 7;

[0068] 2) A certain quality of Co 3 o 4 Add it into the second mixed solution, stir and mix, evaporate to dryness, and roast at 1000 degrees in an oxygen atmosphere for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com