Preparation method of reinforced electrostatic spinning nano-fiber lithium-ion battery separator

A nanofiber membrane, lithium-ion battery technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of short storage period and limited range, and achieve the effects of easy operation, smooth surface, and reduced internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

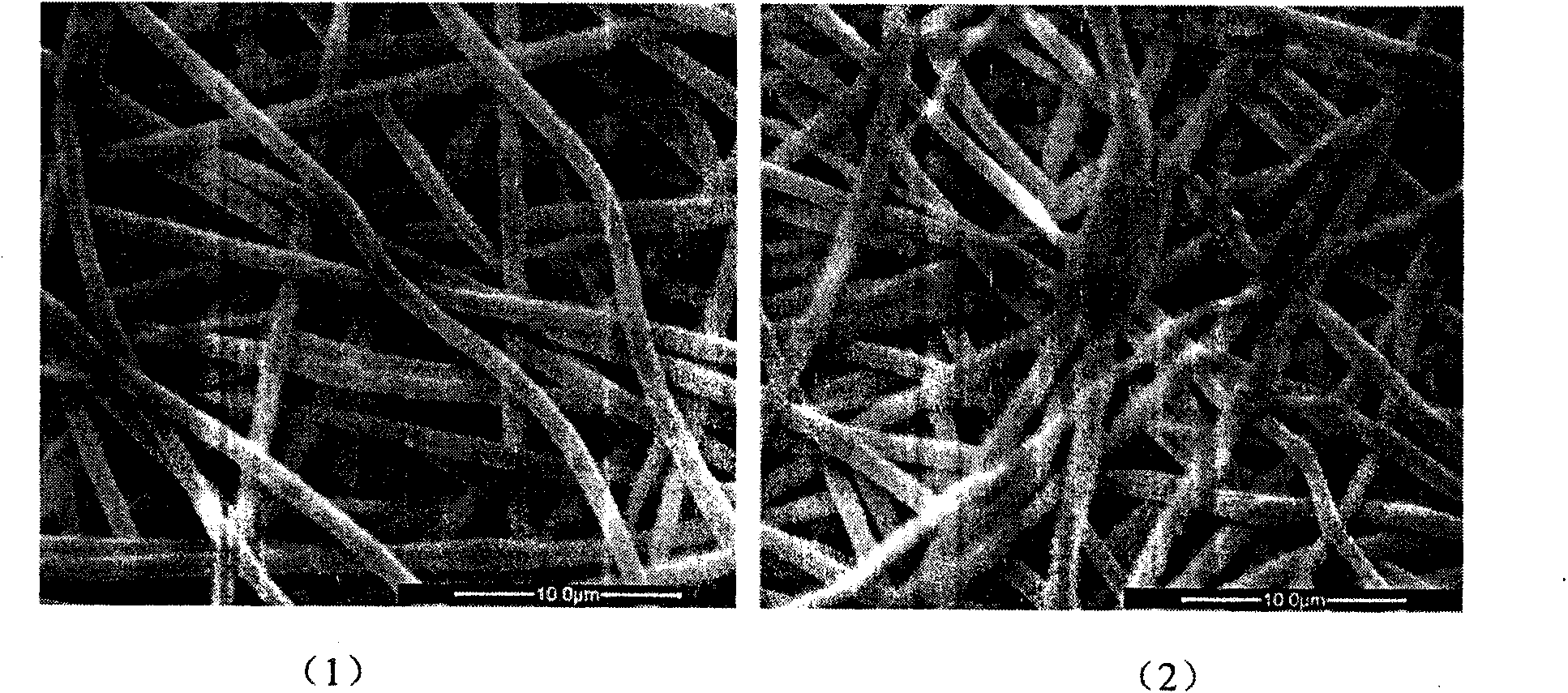

[0033] Dissolve PVDF and P(VDF-HFP) in a mass ratio of 0.95:0.05 in a mixed solvent with N.N-dimethylformamide and acetone at a mass ratio of 7; 3, and configure a solution with a mass fraction of 16%. Heat and stir at -50°C until the polymer is fully dissolved to obtain a spinning solution. The obtained spinning solution was injected into a syringe with a flat needle, the needle was connected to a high-voltage power supply, and the other end 20 cm away from the syringe was a grounded metal receiving device. Adjust the injection speed of the syringe pump to 0.1ml / h, and slowly increase the voltage to 15kv. The rice solution is sprayed out from the needle of the syringe, stretched under the action of a high-voltage electric field, and collected on the aluminum foil of the metal receiving device in the form of a fiber film, and the resulting non-woven film is placed in a vacuum drying oven, and it is operated at room temperature and reduced pressure for 10 hours. After there is...

Embodiment 2

[0038] Dissolve PAN and P(VDF-HFP) in N,N-dimethylformamide solvent at a mass ratio of 0.7:0.3, configure a solution with a mass fraction of 18%, heat and stir at 40-50°C until polymerization The substance is fully dissolved to obtain a spinning solution. The obtained spinning solution is injected into a syringe with a flat needle, the needle is connected to a high-voltage power supply, and the other end 15 cm away from the syringe is a grounded metal receiving device. Adjust the injection speed of the syringe pump to 0.8ml / h, and slowly increase the voltage to 18kv. The solution sprayed from the needle of the syringe is stretched under the action of a high-voltage electric field, and is collected in the form of a fiber film on the aluminum foil paper of the metal receiving device. After there is no residual solvent in the medium, take it out to obtain the PAN / P(VDF-HFP) composite nanofiber membrane

[0039] The prepared PAN / P(VDF-HFP) composite nanofiber membrane was placed...

Embodiment 3

[0042] Dissolve PMMA and PVDF at a mass ratio of 0.5:0.5 in a mixed solvent with N,N-dimethylacetamide and acetone at a mass ratio of 7:3, and prepare a solution with a mass fraction of 10%, at 40-50°C Heat and stir until the polymer is fully dissolved to obtain a spinning solution. The obtained spinning solution is injected into a syringe with a flat needle, the needle is connected to a high-voltage power supply, and the other end 25 cm away from the syringe is a grounded metal receiving device. Adjust the injection speed of the syringe pump to 1.0ml / h, and slowly increase the voltage to 20kv. The solution sprayed from the needle of the syringe is stretched under the action of a high-voltage electric field, and is collected in the form of a fiber film on the aluminum foil paper of the metal receiving device. After there is no residual solvent in the medium, take it out to obtain a PMMA / PVDF composite nanofiber membrane.

[0043] Put the prepared PMMA / PVDF composite nanofibe...

PUM

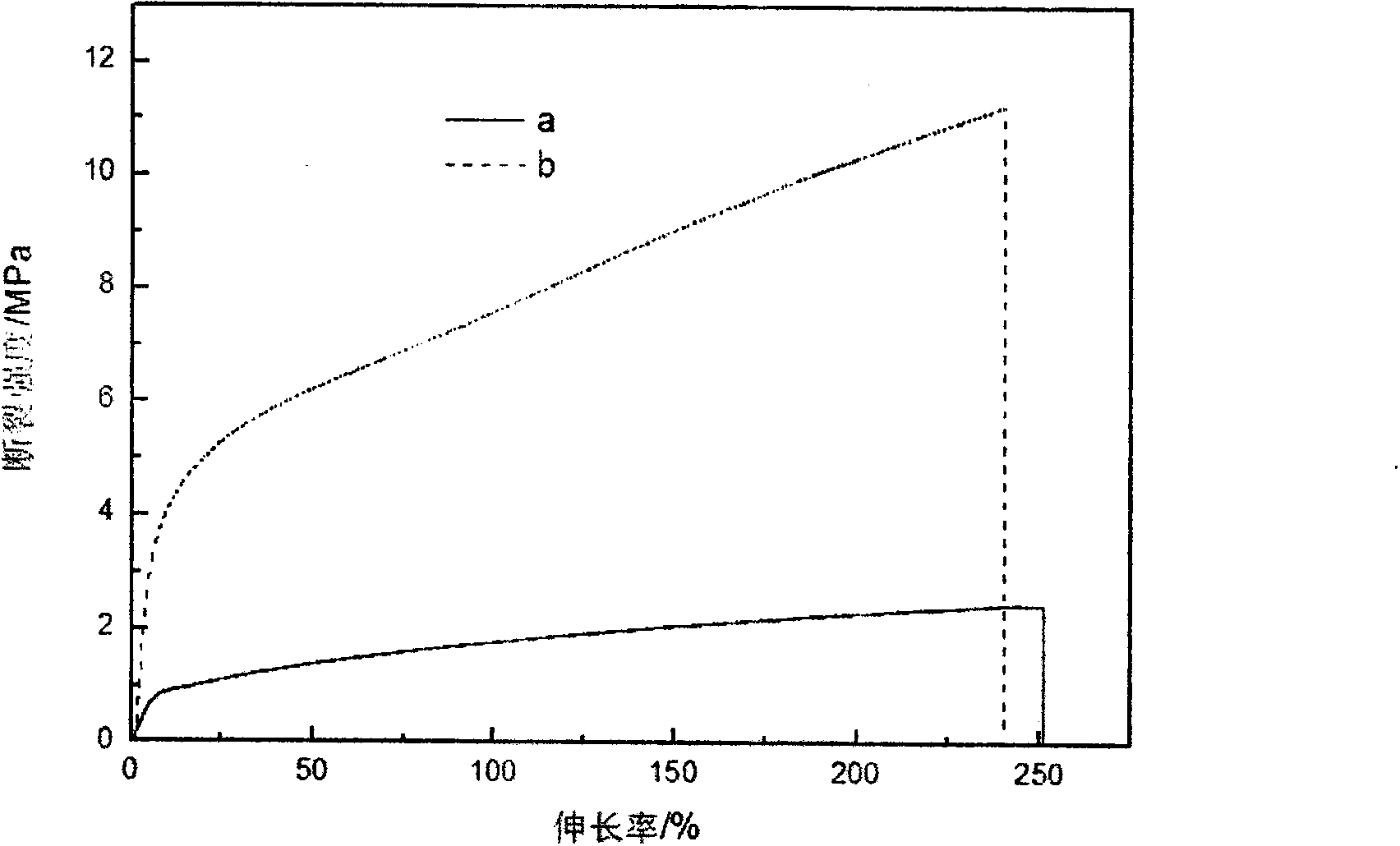

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com