Preparation method of LiCl modified nylon 6 fiber

A technology for modifying nylon and fiber, which is applied in the field of fiber spinning and processing. It can solve the problems of LiCl shedding, short production cycle, easy water absorption and deliquescence, etc., and achieve high draft ratio, short production cycle, high breaking strength and modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

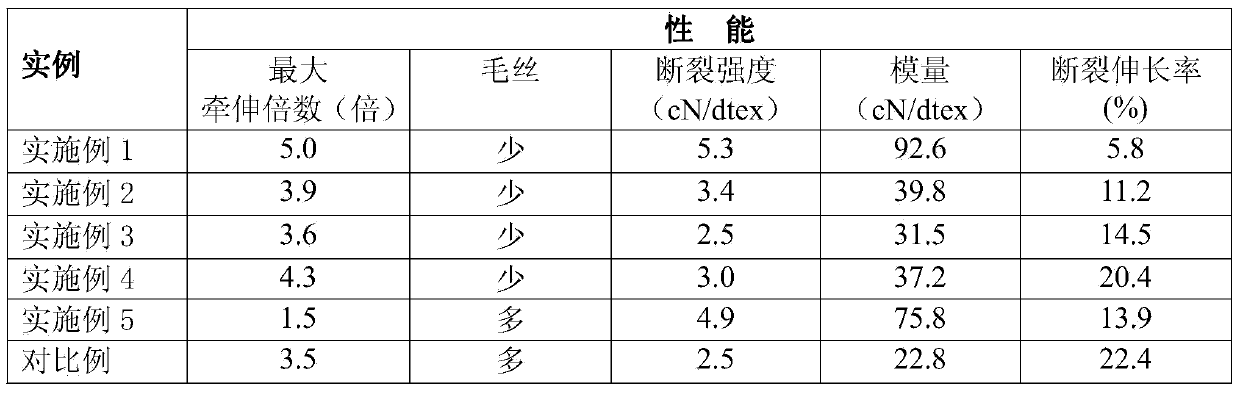

Examples

Embodiment 1

[0038] The LiCl and nylon 6 slices were vacuum-dried separately, the vacuum degree was 0.05KPa, and the proportion of nylon 6 mass fraction was 99.5% and LiCl mass fraction was 0.5%, and the nylon 6 slices were directly mixed with lithium chloride at high speed using a high-speed blender. For blending, the speed of the high-speed mixer is 2000r / min, the heating temperature is 180°C, and the mixing time is 3min. Then melt spinning, the spinning temperature is zone I: 265°C; zone II: 280°C; zone III: 280°C; zone IV: 282°C. The spinning speed is 800m / min, the coiled yarn is drawn twice, the temperature of the hot plate of the flat drawing machine is 60°C, the temperature of the hot plate is 120°C, the draw ratio is 5 times, and the hot water at 90°C is added Hydrazine hydrate with a content of 0.001% of the solvent mass, and then the fiber was washed with the hot water for 30 minutes, and the pump pressure was 2Kgf; after that, it was heat-set at 120°C for 30 minutes, and the vac...

Embodiment 2

[0040] The LiCl and nylon 6 slices were vacuum-dried separately, the vacuum degree was 0.1KPa, and the proportion of nylon 6 mass fraction was 98.5% and LiCl mass fraction was 1.5%, and the nylon 6 slices were directly mixed with lithium chloride at high speed using a high-speed blender. For blending, the speed of the high-speed mixer is 2500r / min, the heating temperature is 185°C, and the mixing time is 2min. Then melt spinning, the spinning temperature is zone I: 265°C; zone II: 280°C; zone III: 280°C; zone IV: 282°C. The spinning speed is 800m / min, the coiled yarn is drawn twice, the temperature of the hot plate of the flat drawing machine is 60°C, the temperature of the hot plate is 120°C, the draw ratio is 4.0 times, and the NaOH solution at 70°C is added Antioxidant 168 with a content of 0.005% of the mass of the solvent, and then press-wash the fiber with the solution for 1.5 hours, and the pump pressure is 1Kgf; then heat-set at 100°C for 1 hour, and the vacuum degree ...

Embodiment 3

[0042] The LiCl and Nylon 6 slices were vacuum-dried separately at a vacuum degree of 10KPa. According to the ratio of Nylon 6 mass fraction of 97.5% and LiCl mass fraction of 2.5%, Nylon 6 slices were directly mixed with lithium chloride at high speed using a high-speed blender. Mixing, the speed of the high-speed mixer is 3500r / min, the heating temperature is 170°C, and the mixing time is 4min. Then melt spinning, the spinning temperature is zone I: 260°C; zone II: 283°C; zone III: 280°C; zone IV: 282°C. The spinning speed is 800m / min, and the coiled yarn is drawn twice. The temperature of the hot plate of the flat drawing machine is 70°C, the temperature of the hot plate is 130°C, and the draw ratio is 4.0 times. Add it to the ethanol solution at 60°C Antioxidant 3114 with a content of 0.08% of the solvent mass, and then the fiber was pressure washed with the solution for 2 hours, and the pump pressure was 3Kgf; after that, it was heat-set at 125°C for 20 minutes, and the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com