Distillation and deodorization method for production of biodiesel

A biodiesel and deodorization technology, which is applied in the fields of biofuels, petroleum industry, and fat production, can solve the problems of low vacuum efficiency of vacuum units, odor of finished biodiesel products, and high thermal energy consumption of biodiesel, so as to achieve stable operation and high thermal energy consumption. The effect of decreasing and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

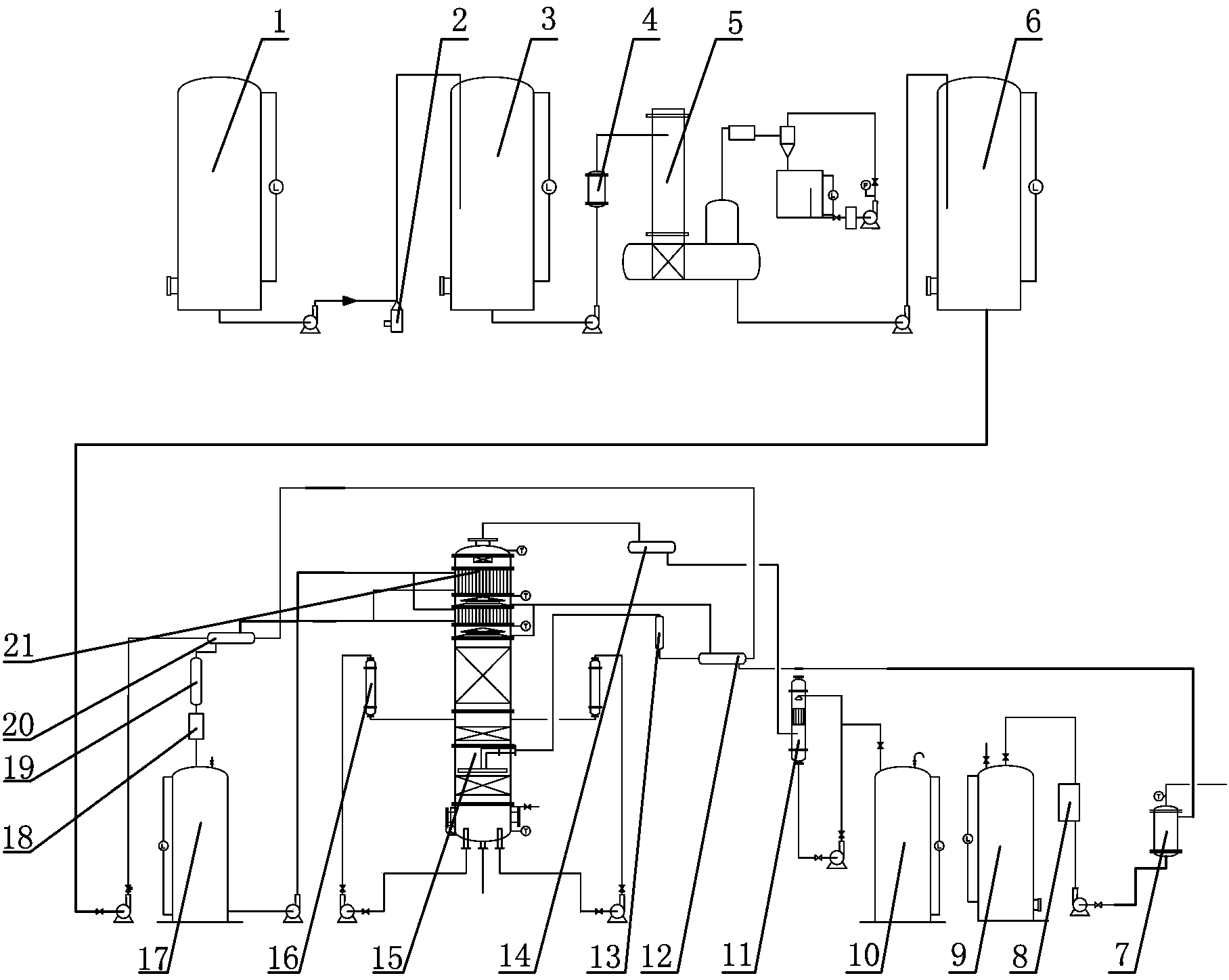

[0011] The crude methyl ester produced after the reaction of raw oil and methanol contains water, glycerin and soap after washing, such as figure 1 As shown, the crude methyl esters washed with water in the deglycerinated soap crude methyl ester temporary storage tank 1 are pumped into the disc centrifuge 2 for centrifugation for 10-15 seconds. After centrifugation, the lower layer is a mixture of water, glycerin and soap. The upper layer is the crude methyl ester containing 0.5% to 1.0% water, and the soap in the crude methyl ester is completely separated. The mixed phase of the lower layer is released from the bottom of the butterfly centrifuge 2, and the upper layer of water-containing crude methyl ester is transferred to the temporary storage tank 3 of the water-containing crude methyl ester, and is pumped into the tubular steam heater 4 for heating by an oil pump. After heating to 100-110°C, The crude methyl ester enters the falling film dehydration tower 5 to remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com