Tool wear monitoring method

A tool wear and acoustic emission signal technology, applied in the field of tool wear detection, can solve the problems of poor applicability, achieve the effect of improving the recognition rate and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

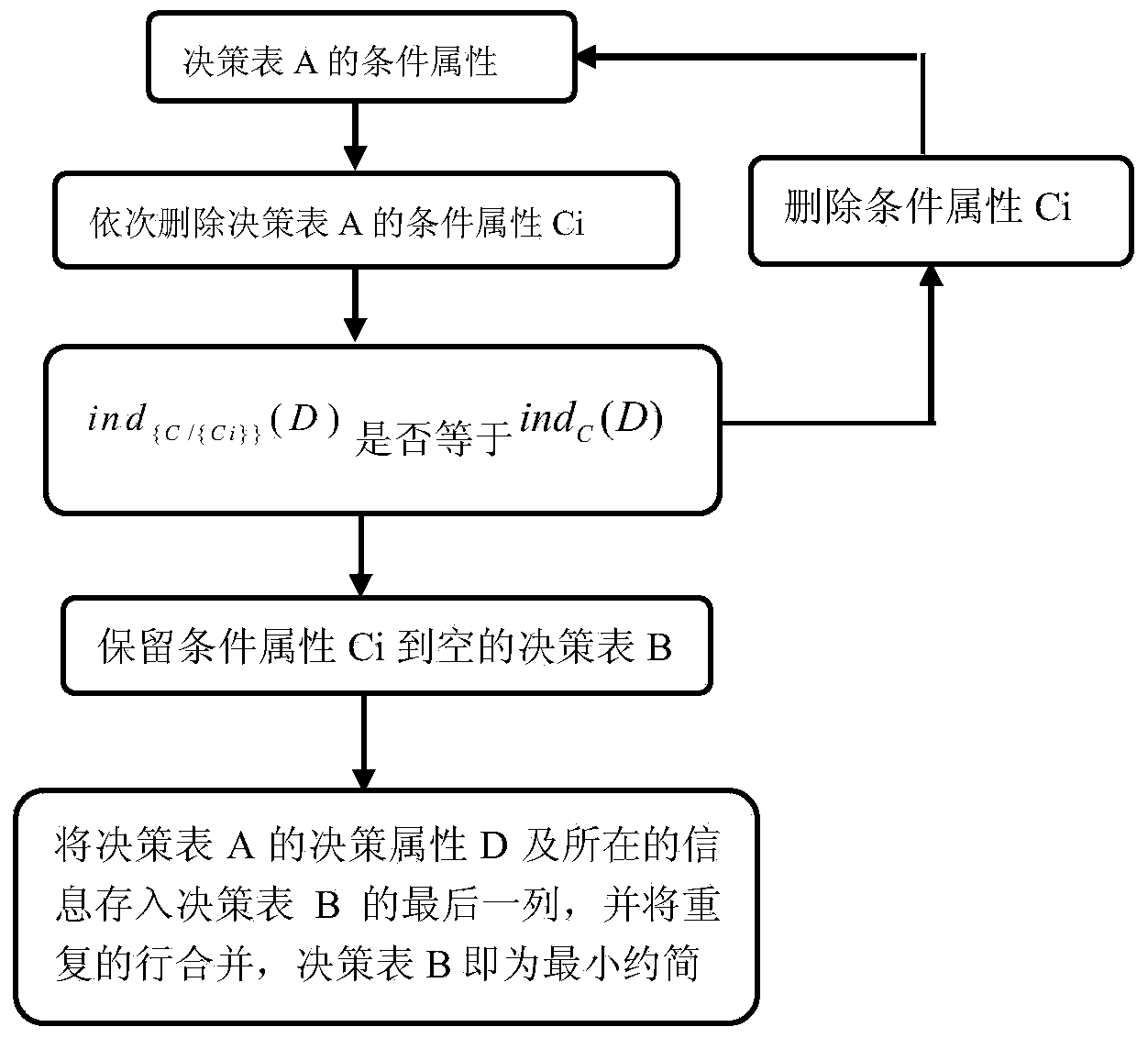

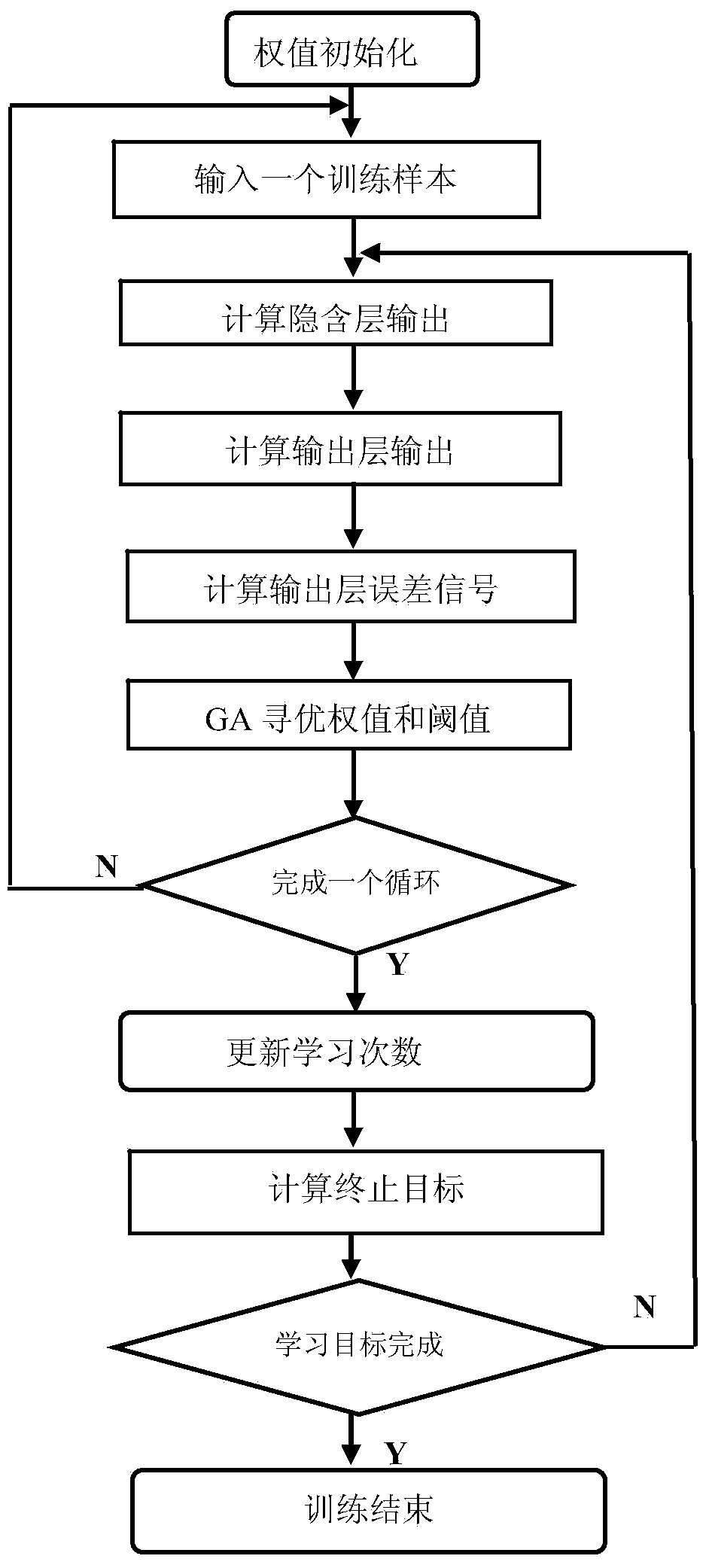

Method used

Image

Examples

Embodiment

[0046] The superalloy GH4169 was turned with YBC carbide inserts on a CA6140 ordinary lathe.

[0047] A current sensor with the model number HZIB-C11-100P2O5 is used to monitor the state of the cutting tool. The acquisition device is a PCI-1712 data acquisition card produced by Advantech, and the sampling frequency is 1M Hz. Choose 8 different cutting parameters, collect the acoustic emission signals and current signals of 3 different wear states, and get 40 sets of signals in total. For the acoustic emission signal, extract the amplitude root mean square and the maximum power in the frequency domain, and the 8 frequency band energies of the three-layer decomposition of the db8 wavelet packet as eigenvalues; the eight frequency band energies of the three-layer decomposition of the db8 wavelet packet for the current signal are used as The eigenvalues, together with the cutting speed, depth of cut and feed rate, constitute a 21-dimensional vector, which serves as an eigenvector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com