Method for manufacturing paperboard

A manufacturing method and technology of cardboard, applied in the field of cardboard manufacturing, can solve the problems of poor retention of paper strength enhancer and inability to give full play to the effect of paper strength enhancer, so as to solve the problems of retention, paper strength, etc. Enhanced Effects with Excellent Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

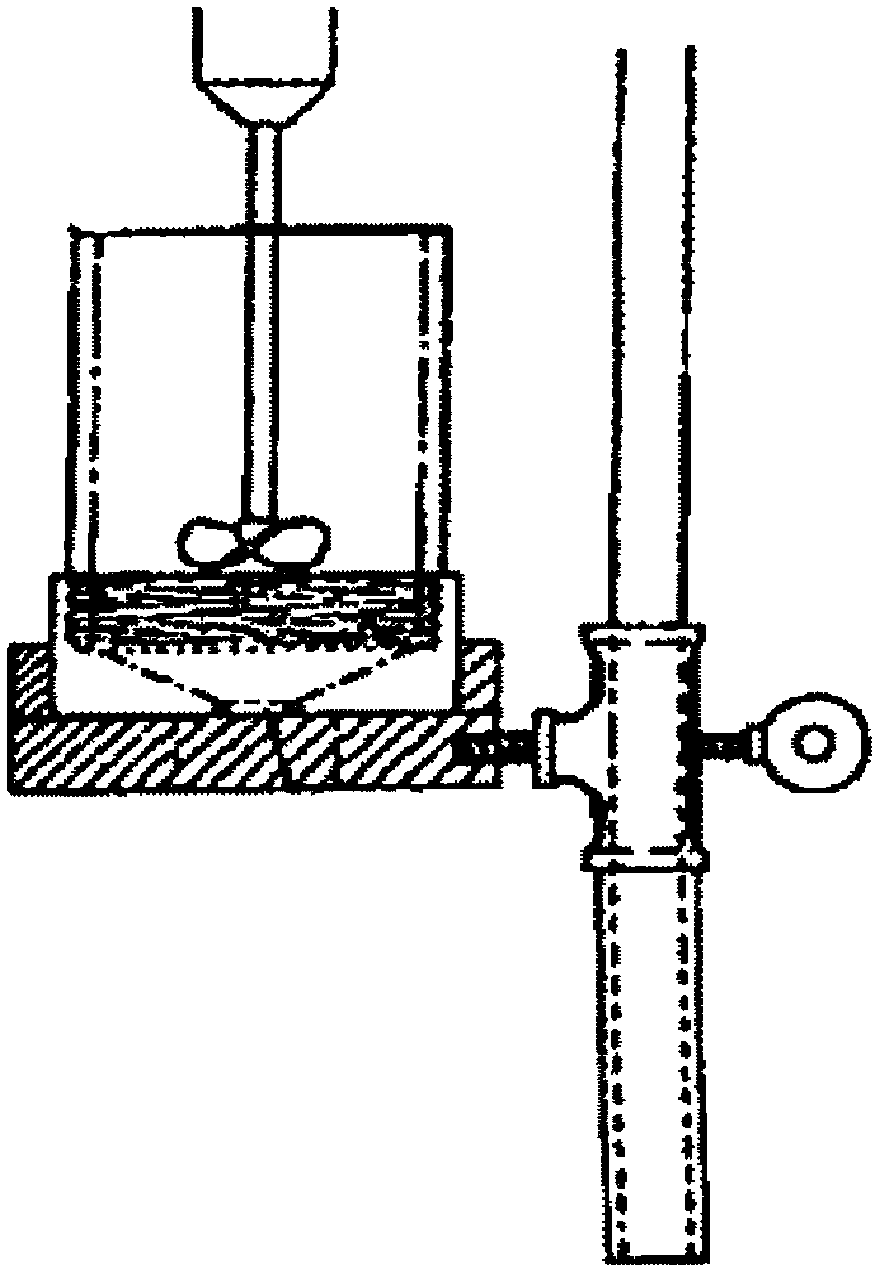

Method used

Image

Examples

manufacture example 1

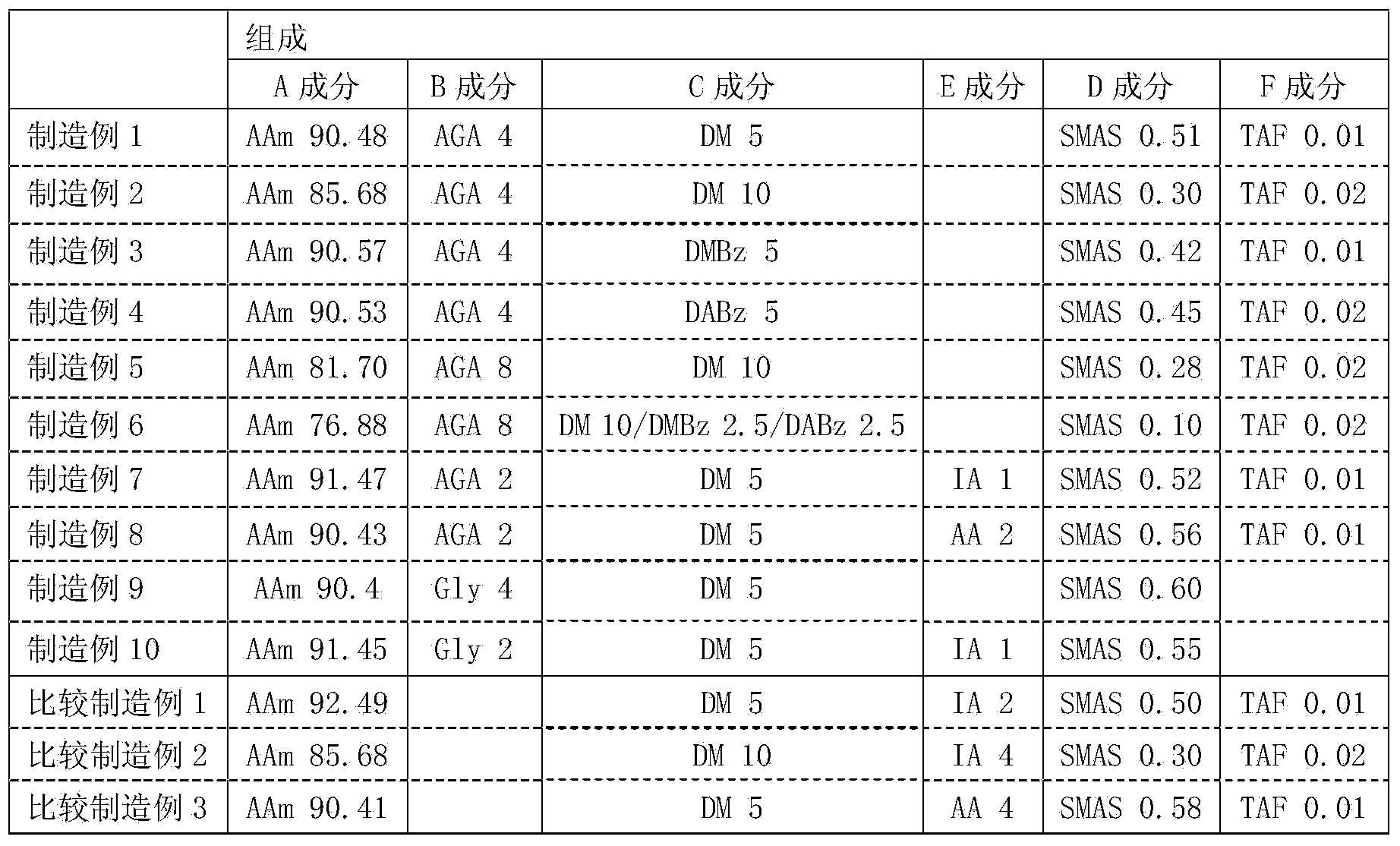

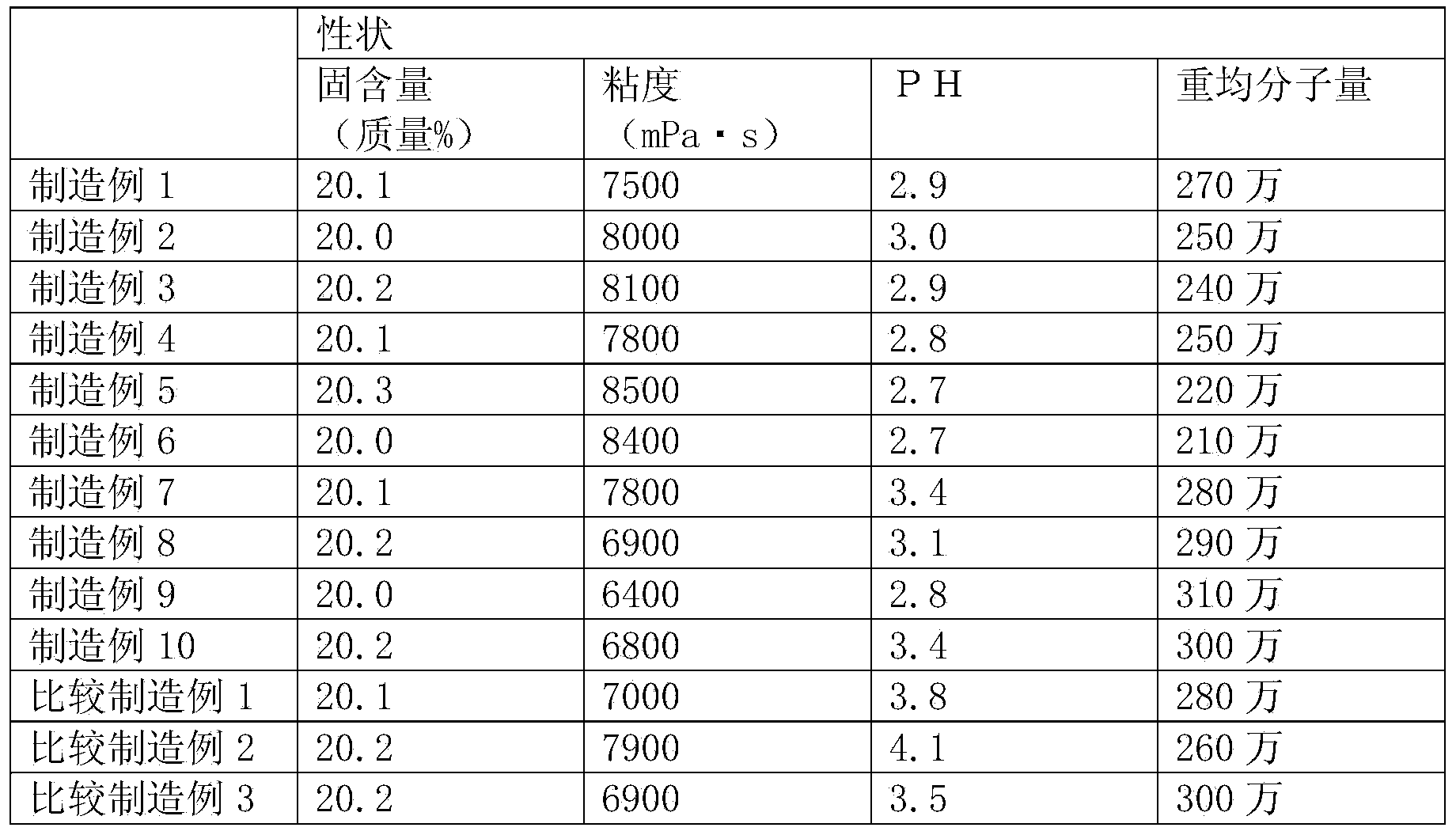

[0117] Put 610.1 g of ion-exchanged water, 315.17 g of 50% acrylamide aqueous solution, 19.28 g of dimethylaminoethyl methacrylate, and 2- Acrylamide-N-glycolic acid 14.22g, 1,3,5-triacryloylhexahydro-1,3,5-triazine (triacrylformal) 0.06g, sodium methallyl sulfonate 1.97g, then put into 30 % sulfuric acid aqueous solution 15.93g, take PH3.0, heat up to 60 ℃ under nitrogen atmosphere. Then, 5.59 g of a 5% ammonium persulfate aqueous solution was added as a polymerization initiator, and the temperature was raised to 90° C. under a nitrogen atmosphere, and the temperature was kept. One hour after the start of the polymerization, 11.17 g of 5% ammonium persulfate was additionally added, and the polymerization was stopped 2 hours after the start of the reaction. After cooling, a polymer-containing aqueous solution with a solid content of 20.1%, a viscosity (using a Brookfield rotational viscometer at 25° C.) of 7500 mPa·s, and a pH of 2.9 was obtained. The properties of the obtai...

manufacture example 2~8、 comparative manufacture example 1~3

[0119] As shown in Table 1, except that the types and molar ratios of (A) to (F) components were changed, the same operation as in Production Example 1 was carried out to obtain a polymer-containing aqueous solution. The properties of the obtained polymer-containing aqueous solution are shown in Table 2.

manufacture example 9

[0121]Put 576.0 g of ion-exchanged water, 315.23 g of 50% acrylamide aqueous solution, 19.28 g of dimethylaminoethyl methacrylate, and 50% 14.53 g of glyoxylic acid, 2.33 g of sodium methallyl sulfonate, and then 15.25 g of 30% sulfuric acid aqueous solution was added to obtain a pH of 3.0, and the temperature was raised to 60° C. under a nitrogen atmosphere. Then, 5.59 g of a 5% ammonium persulfate aqueous solution was added as a polymerization initiator, and the temperature was raised to 90° C. under a nitrogen atmosphere, and the temperature was kept. One hour after the start of the polymerization, 11.17 g of 5% ammonium persulfate was additionally added, and the polymerization was stopped 2 hours after the start of the reaction. After cooling, a polymer-containing aqueous solution with a solid content of 20.0%, a viscosity of 6400 mPa·s, and a pH of 2.8 was obtained. The properties of the obtained polymer-containing aqueous solution are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com