Organic cathode material for sodium ion battery

A sodium ion battery, organic negative electrode technology, applied in battery electrodes, circuits, electrical components and other directions, can solve problems such as the inability to apply sodium ion battery system well, achieve stable electrochemical cycle performance, simple synthesis method, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

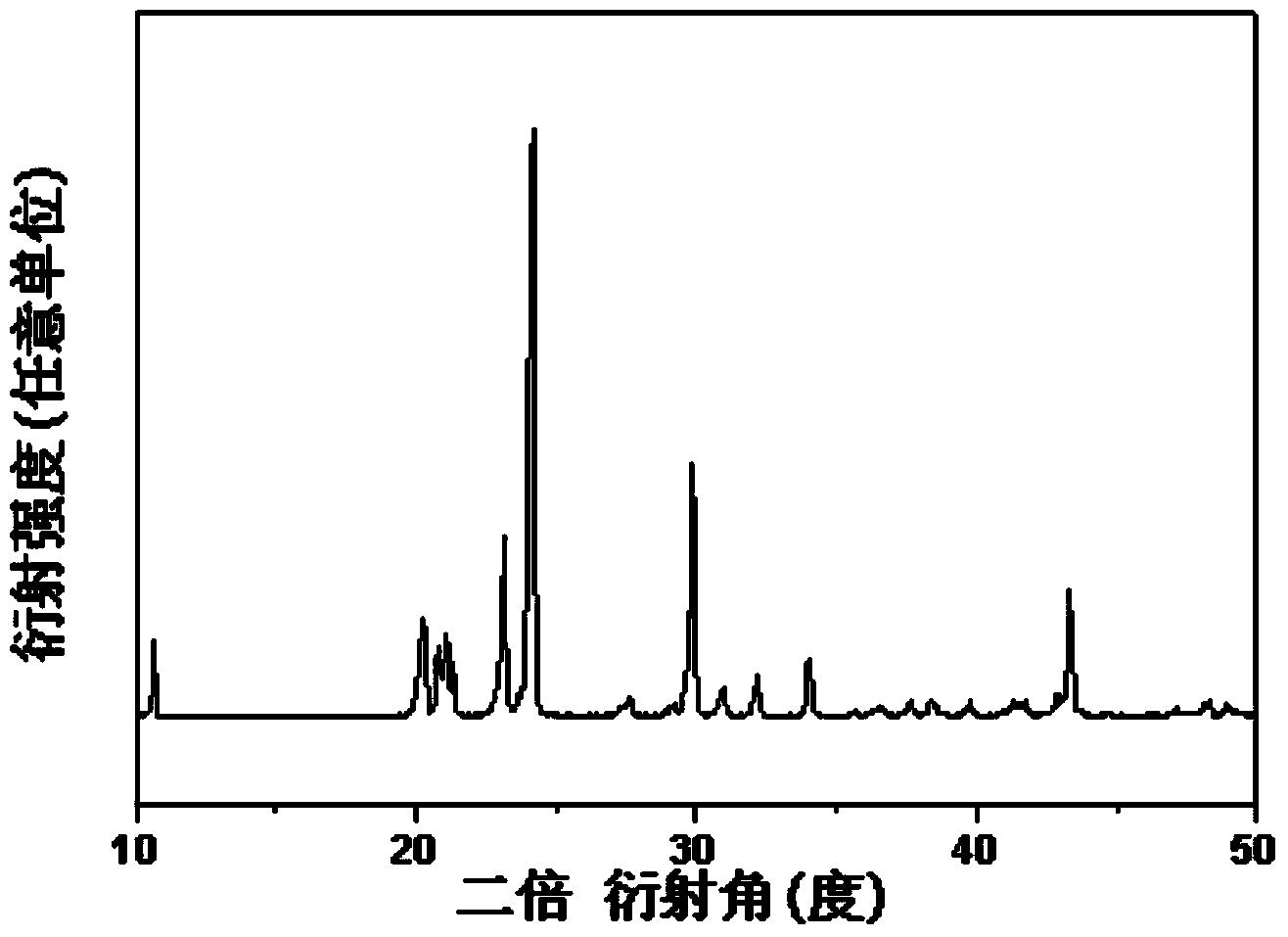

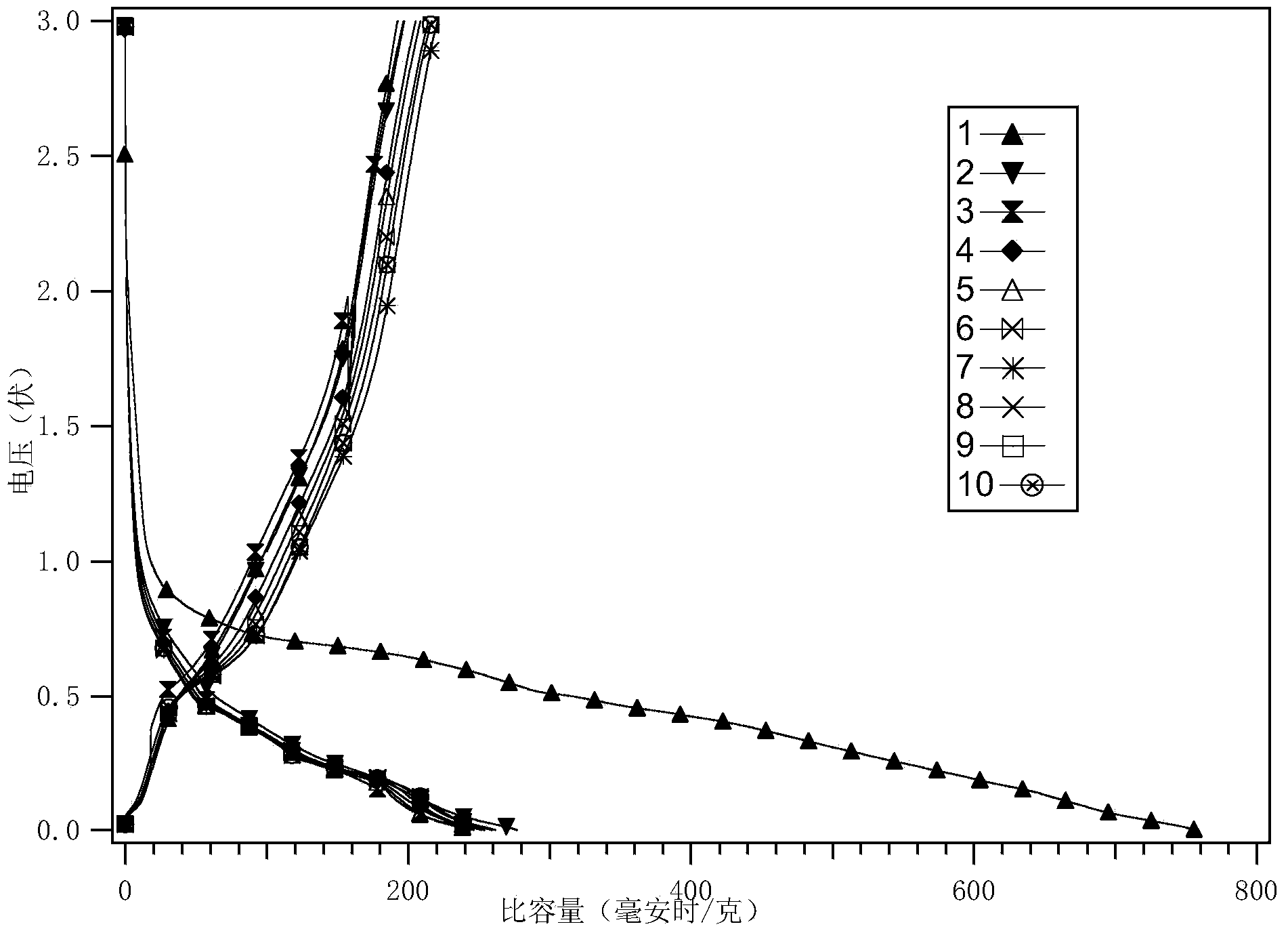

[0056] Preparation of organic anode material C for sodium ion battery 8 H 4 O 4 Li 2 . The specific method is as follows: first weigh 0.5 mol of terephthalic acid, pour it into the reaction flask, add 200 ml of water, stir evenly with a glass rod, then weigh 1 mol of lithium hydroxide, and add 0.5 mol of terephthalic acid In the reaction flask, stir evenly with a glass rod, and then continue to add water to 500ml, stir evenly with a glass rod, and place in a constant temperature oven at 80°C for 24 hours to fully react, and obtain a clear and transparent solution, which is C 8 H 4 O 4 Li 2 Aqueous solution. Will C 8 H 4 O 4 Li 2 The aqueous solution was transferred to a blast drying oven at 100℃ for drying, and the water in the solution was removed to obtain C 8 H 4 O 4 Li 2 Powder samples. Weigh 120mg of C 8 H 4 O 4 Li 2 Put the powder in an agate mortar, grind for 5 minutes, weigh 60mg of acetylene black into the agate mortar, continue to grind for 10 minutes, and then add 1m...

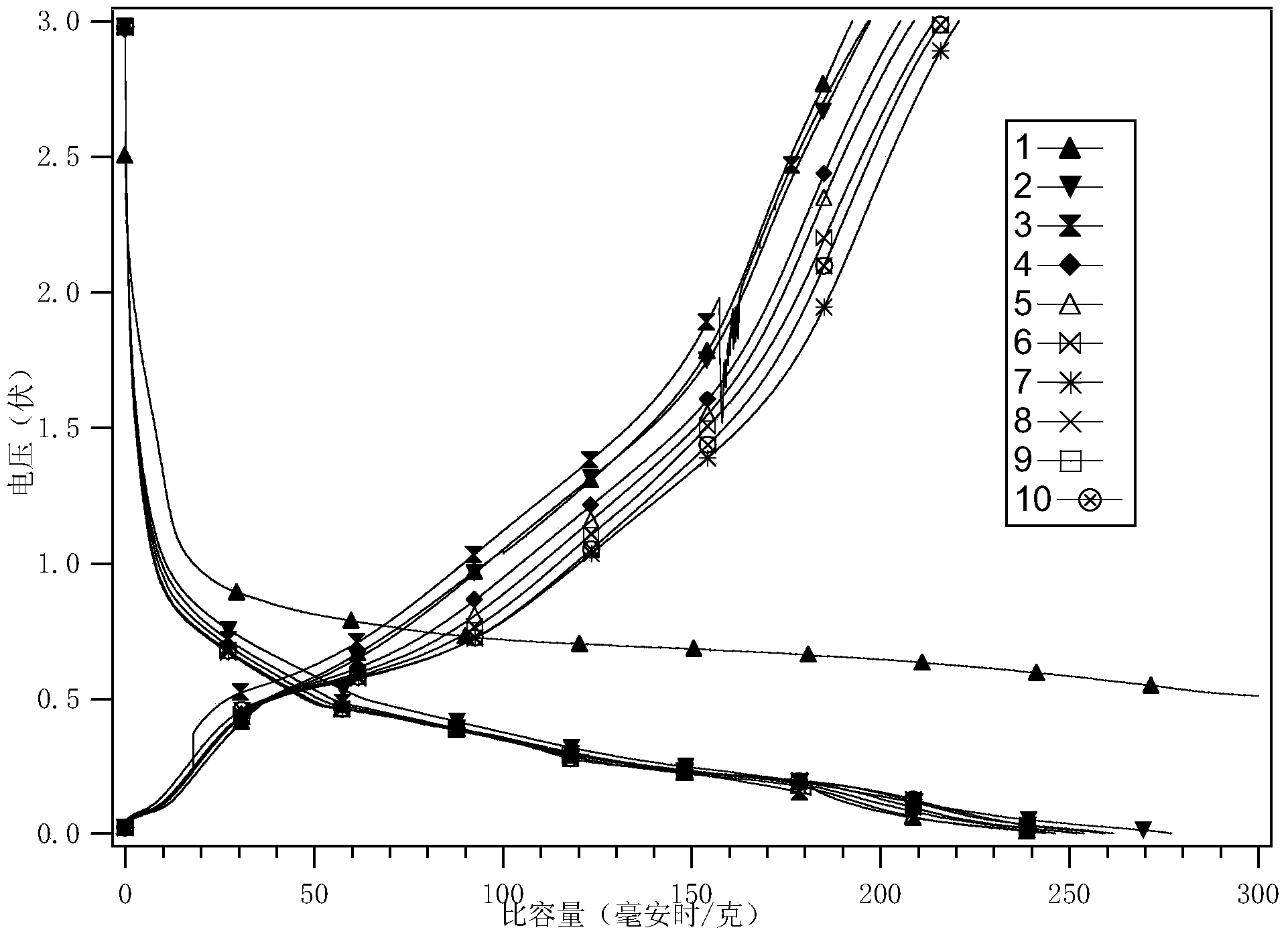

Embodiment 2

[0059] Preparation of organic anode material C for sodium ion battery 8 H 4 O 4 Ca. The specific method is as follows: first weigh 0.5 mol of terephthalic acid, pour it into the reaction flask, add 200 ml of water, stir evenly with a glass rod, then weigh 1 mol of lithium hydroxide, and add 0.5 mol of terephthalic acid In the reaction flask, stir evenly with a glass rod, and then continue to add water to 500ml, stir evenly with a glass rod, and place in a constant temperature oven at 80°C for 24 hours to fully react, and obtain a clear and transparent solution, which is C 8 H 4 O 4 Li 2 Aqueous solution. Take 200mlC 8 H 4 O 4 Li 2 Put the aqueous solution in a new beaker, and then add a certain amount of CaCl to the beaker 2 , A large amount of white precipitate is produced in the beaker, which is C 8 H 4 O 4 Ca, continue to add 300ml of deionized water to the beaker, stir evenly with a glass rod, stand still for 1 hour, collect the precipitate C by filtration 8 H 4 O 4 Ca. Was...

Embodiment 3

[0062] Preparation of organic anode material C for sodium ion battery 8 H 4 O 4 Al 2 / 3 . The specific method is as follows: first weigh 0.5 mol of terephthalic acid, pour it into the reaction flask, add 200 ml of water, stir evenly with a glass rod, then weigh 1 mol of lithium hydroxide, and add 0.5 mol of terephthalic acid In the reaction flask, stir evenly with a glass rod, and then continue to add water to 500ml, stir evenly with a glass rod, and place in a constant temperature oven at 80°C for 24 hours to fully react, and obtain a clear and transparent solution, which is C 8 H 4 O 4 Li 2 Aqueous solution. Take 200mlC 8 H 4 O 4 Li 2 The aqueous solution is placed in a new beaker, and then a certain amount of Al(NO 3 ) 3 , A large amount of white precipitate is produced in the beaker, which is C 8 H 4 O 4 Al 2 / 3 , Continue to add 300ml of deionized water to the beaker, stir evenly with a glass rod, stand still for 1h, collect the precipitate C by filtration 8 H 4 O 4 Al 2 / 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com