Surface treatment process of bioactive metallic titanium implant having multistage micro-pit structure

A biological activity and surface treatment technology, applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of high cost, inability to realize large-scale production, long bone healing cycle, complicated process, etc., to achieve Shorter surgical healing time, faster healing speed, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0024] In this example, the steps of machining a cylindrical threaded titanium implant are:

[0025] a. Pretreatment: provide a metal titanium implant that has been machined and finely ground, and use acetone, absolute ethanol, and purified water to perform ultrasonic cleaning and degreasing treatment on the surface of the metal titanium implant twice each, Five minutes at a time; to clean and degrease, then dry.

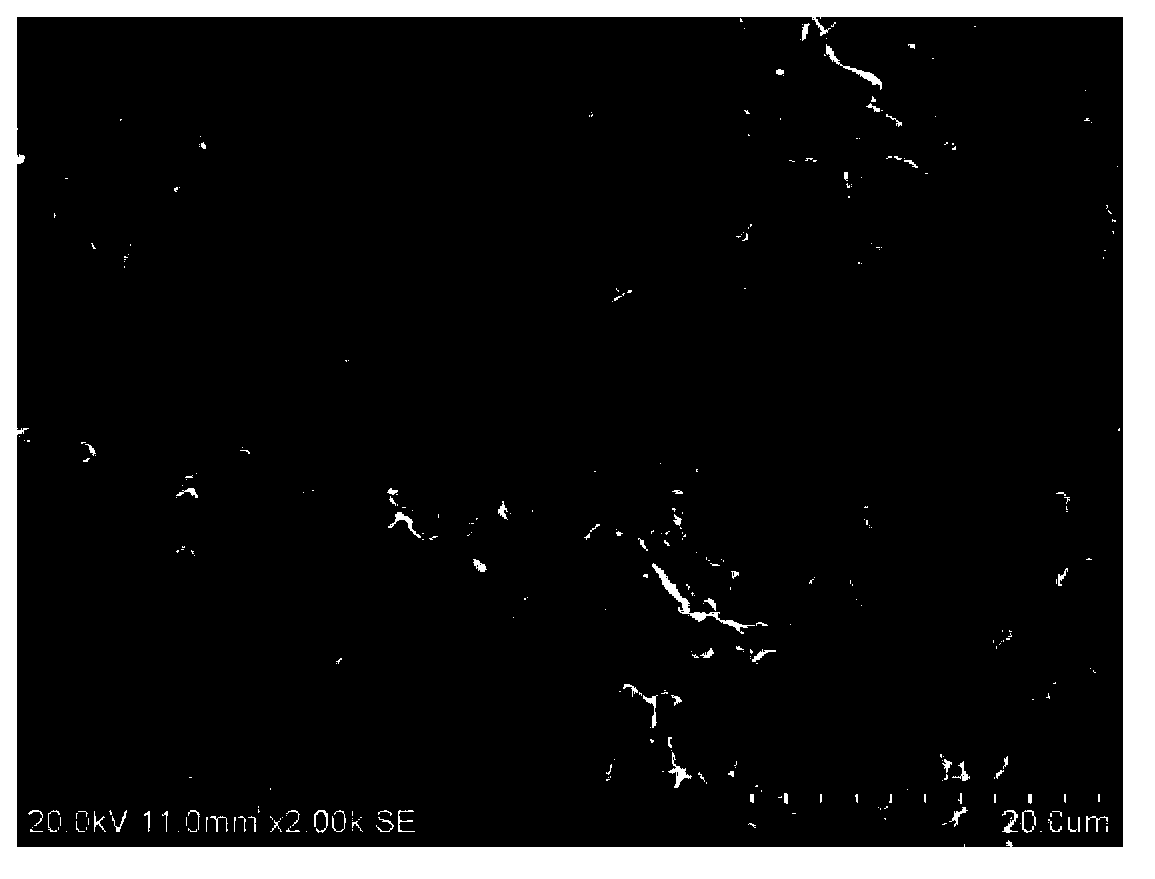

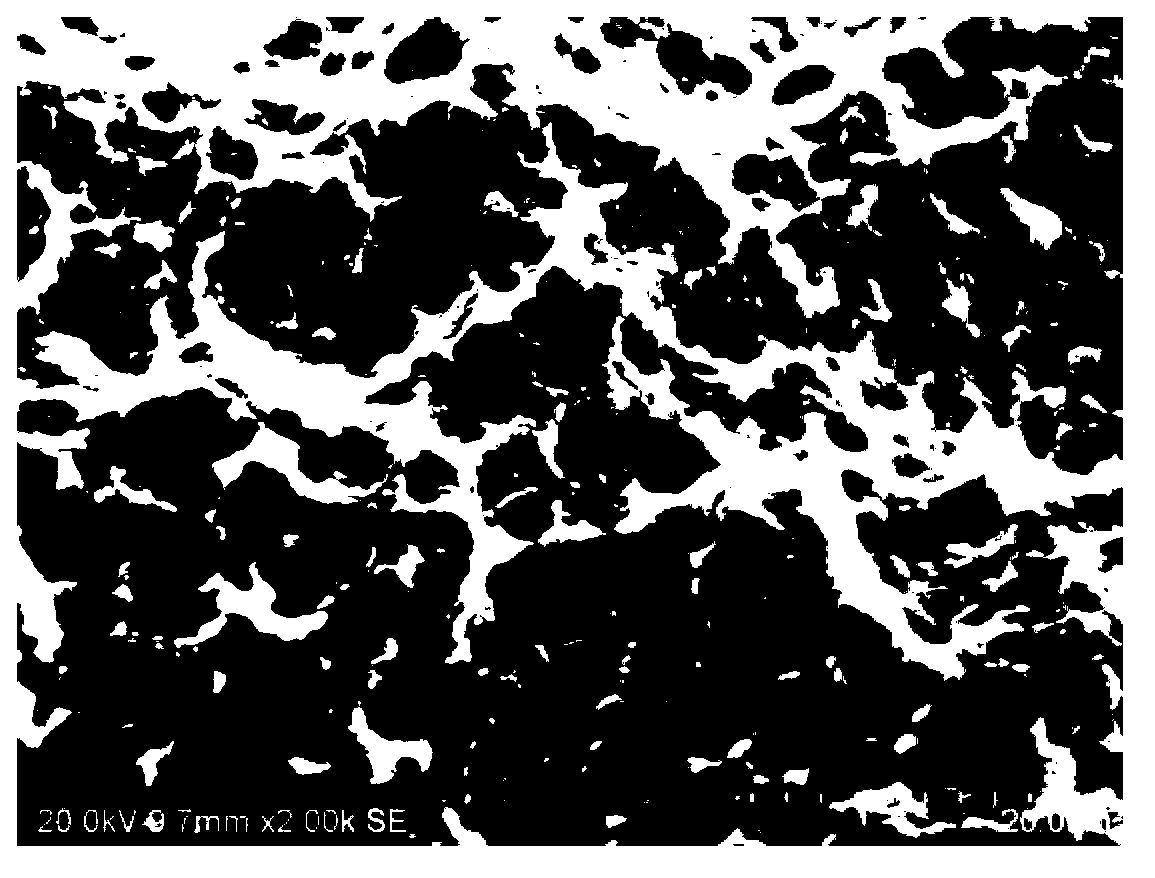

[0026] b. Sandblasting treatment: Use 24-70 mesh white corundum to perform sandblasting treatment on the surface of the pretreated titanium metal implant. The axial direction of the spray gun metal titanium implant is 45°. 0.5Mpa, the spray distance is 10cm, sandblasting until the surface of metal titanium implants is uniform gray, so that the surface of metal titanium implants forms a porous three-dimensional structure, the roughness Ra is 3μm; the diameter of the pits of the porous structure is 10-40μm First-level pits, and perform pure hydration ultrasonic clean...

Embodiment 2)

[0031] In this example, the steps of machining a cylindrical threaded titanium implant are:

[0032] a. Pretreatment: provide a metal titanium implant that has been machined and finely ground, and use acetone, absolute ethanol, and purified water to perform ultrasonic cleaning and degreasing treatment on the surface of the metal titanium implant twice each, Five minutes at a time; to clean and degrease, then dry.

[0033] b. Sandblasting treatment: Use 24-70 mesh white corundum to perform sandblasting treatment on the surface of the pretreated titanium metal implant. The axial direction of the spray gun metal titanium implant is 45°. 0.5Mpa, the spray distance is 10cm, sandblasting until the surface of metal titanium implants is uniform gray, so that the surface of metal titanium implants forms a porous three-dimensional structure, the roughness Ra is 3μm; the diameter of the pits of the porous structure is 10-40μm First-level pits, and perform pure hydration ultrasonic clean...

Embodiment 3)

[0038] In this example, the steps of machining a cylindrical threaded titanium implant are:

[0039] a. Pretreatment: provide a metal titanium implant that has been machined and finely ground, and use acetone, absolute ethanol, and purified water to perform ultrasonic cleaning and degreasing treatment on the surface of the metal titanium implant twice each, Five minutes at a time; to clean and degrease, then dry.

[0040]b. Sandblasting treatment: Use 24-70 mesh white corundum to perform sandblasting treatment on the surface of the pretreated titanium metal implant. It is 0.4Mpa, the spray distance is 8cm, sandblasting until the surface of the metal titanium implant is uniform gray, so that the surface of the metal titanium implant forms a porous three-dimensional structure, the roughness Ra is 4μm; the diameter of the pit of the porous structure is 10-40μm First-level pits, and perform pure hydration ultrasonic cleaning and drying;

[0041] c. Acid etching treatment: soak t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com