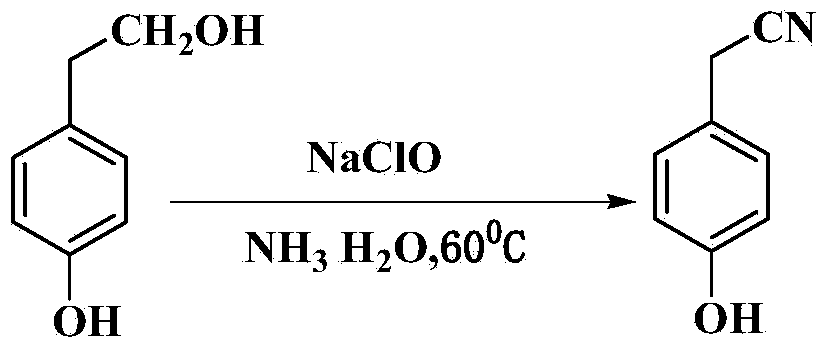

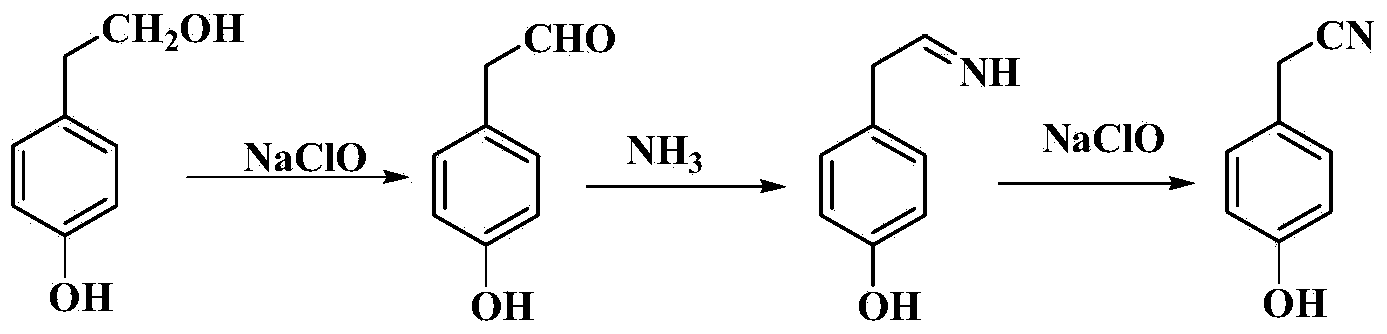

Method for preparing para hydroxybenzene acetonitrile

A technology of hydroxyphenylacetonitrile and p-hydroxyphenylethanol, which is applied in the field of organic chemical synthesis, can solve the problem of high price, and achieve the effects of short route, mild reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 4.56 g (0.033 mol) of p-hydroxyphenethyl alcohol and 8.8 mL (0.132 mol) of ammonia water (28 wt%) into a 100 mL three-necked flask (equipped with a thermometer, magnetic stirring, reflux condenser and constant pressure dropping funnel), and the reaction mixture Heat to 50°C to dissolve p-hydroxyphenethyl alcohol, then slowly add 36.3mL (0.073mol) of 6.5wt% sodium hypochlorite aqueous solution dropwise, and control the reaction temperature at 50°C. Reaction adopts TLC detection reaction to carry out degree, developing agent sherwood oil / ethyl acetate (volume ratio 2:1), the R of p-hydroxyphenylacetonitrile f About = 0.6. After 20 hours of reaction, the reaction was completed, and the reaction solution was cooled to about 0°C to crystallize. After suction filtration and drying, 4.13 g of p-hydroxybenzonitrile was obtained, with a yield of 95.0% and a purity of 98.8% by gas chromatography.

[0025] m.p.: 69-71°C;

[0026] 1 HNMR (CDCl 3 , 400M), TMS): δ3.63 (s, 2H...

Embodiment 2

[0028] Add 9.12 grams (0.066mol) of p-hydroxyphenylethyl alcohol and 17.6mL (0.264mol) of ammonia water (28wt%) into a 250mL three-neck flask (equipped with a thermometer, magnetic stirring, reflux condenser and constant pressure dropping funnel), and the reaction mixture Heat to 60°C to dissolve p-hydroxyphenethyl alcohol. Then, 99.0 mL (0.198 mol) of 6.5 wt % sodium hypochlorite aqueous solution was slowly added dropwise, and the reaction temperature was controlled at 60 °C. The progress of the reaction was detected by TLC. After 10 hours of reaction, the reaction was completed, and the reaction solution was cooled to about 0°C to crystallize. After suction filtration and drying, 8.63 g of p-hydroxybenzonitrile was obtained with a yield of 98.2% and a purity of 99.0% by gas chromatography.

Embodiment 3

[0030] Add 9.12 grams (0.066mol) of p-hydroxyphenylethyl alcohol and 16.0mL (0.30mol) of ammonia water (35wt%) into a 250mL three-necked flask (equipped with a thermometer, magnetic stirring, reflux condenser and constant pressure dropping funnel), and the reaction mixture Heat to 60°C to dissolve p-hydroxyphenethyl alcohol. Then, 99.0 mL (0.198 mol) of 6.5 wt % sodium hypochlorite aqueous solution was slowly added dropwise, and the reaction temperature was controlled at 60 °C. The progress of the reaction was detected by TLC. After reacting for 9 hours, the reaction was completed, and the reaction solution was cooled to about 0°C to crystallize. After suction filtration and drying, 8.65 g of p-hydroxybenzonitrile was obtained with a yield of 98.4% and a purity of 99.2% by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com