Zirconia ceramic piece and preparation method thereof

A technology of zirconia ceramics and zirconia, which is applied in the field of zirconia ceramic chess pieces and its preparation, and can solve the problem that the shell cannot be used for other purposes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

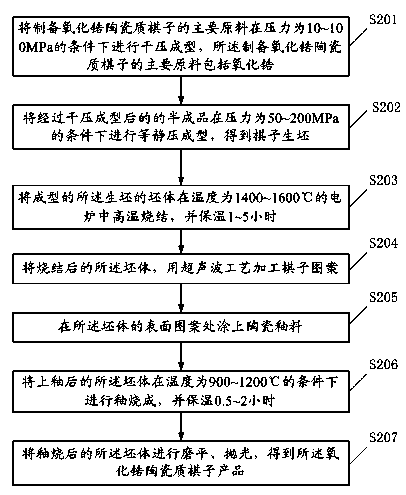

[0056] Correspondingly, as figure 1 As shown, the embodiment of the present invention provides a method for preparing a zirconia ceramic chess piece, which includes the following steps in turn:

[0057] S101, the main raw material for preparing zirconia ceramic chess pieces is formed by dry pressing and isostatic pressing to obtain a chess piece green body, wherein the main raw material for preparing zirconia ceramic chess pieces includes zirconia.

[0058] Preferably, the pressure of the dry pressing is 10-100 MPa, and the pressure of the isostatic pressing is 50-200 MPa.

[0059] Further preferably, the dry pressing forming pressure is 50 MPa, and the isostatic pressing forming pressure is 100 MPa.

[0060] S102, sintering the shaped body of the green body at a high temperature in an electric furnace, and the high temperature sintering temperature is 1400-1600°C.

[0061] Preferably, the high-temperature sintering temperature is 1400-1600° C., and the temperature is kept for...

Embodiment 1

[0121] The main raw material for preparing zirconia ceramic chess pieces: zirconia powder ZrO 2 90wt%, 6 wt% yttrium oxide, and 4 wt% cerium oxide are filled into the designed dry pressing mold, and dry pressing is performed in a dry pressing molding machine with a pressure of 10 MPa;

[0122] The semi-finished product after dry pressing is subjected to isostatic pressing under a pressure of 50 MPa to obtain a chess piece green body;

[0123] Sintering the shaped body of the green body at a high temperature in an electric furnace at a temperature of 1400° C., and keeping it warm for 1 hour;

[0124] The green body after sintering is processed chess piece pattern with ultrasonic technology;

[0125] Coating red and black ceramic glazes on the surface pattern of the green body;

[0126] The body after glazing is glazed and fired at a temperature of 900° C., and kept warm for 0.5 hours;

[0127] The glazed body is ground on both sides on a grinder, polished on a polishing mac...

Embodiment 2

[0129] The main raw material for preparing zirconia ceramic chess pieces: zirconia powder ZrO 2 94 wt%, 3 wt% yttrium oxide, and 3 wt% cerium oxide are filled into the designed dry pressing mold, and dry pressing is performed in a dry pressing molding machine with a pressure of 30MPa;

[0130] The dry-pressed semi-finished product is subjected to isostatic pressing under a pressure of 30 MPa to obtain a chess piece green body;

[0131] Sintering the shaped body of the green body at a high temperature in an electric furnace at a temperature of 1450° C., and keeping it warm for 2 hours;

[0132] The green body after sintering is processed chess piece pattern with ultrasonic technology;

[0133] Coating red and black ceramic glazes on the surface pattern of the green body;

[0134] The glazed green body is fired at a temperature of 1000° C. and kept warm for 1 hour;

[0135] The glazed body is ground on both sides on a grinder, polished on a polishing machine, and finally the z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com