Low-cost nano aluminum oxide powder preparation method and nano aluminum oxide powder

A nano-alumina, alumina technology, applied in the preparation of alumina/hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of high price, low production and high cost, and achieve easy The effect of industrialized production, improvement of natural environment, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

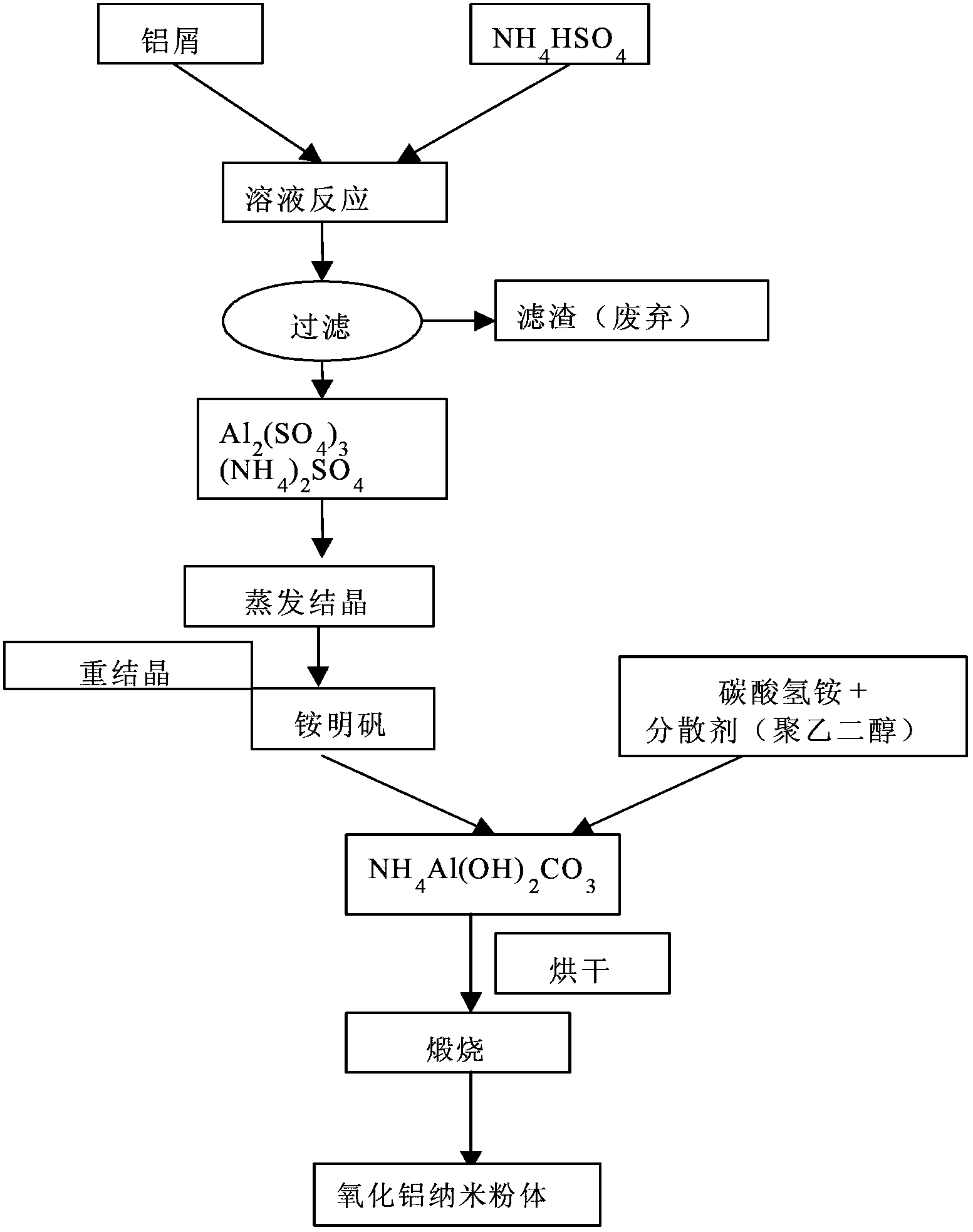

[0024] The preparation method of the present invention is to use industrial waste or cheap intermediate products (these raw materials are cheap but have various impurities) as substitute raw materials to produce nano-alumina powder materials with satisfactory purity. The preparation method of the present invention has two technical keys to be solved: 1) removal of impurities in raw materials; 2) selection of optimal conditions for large-scale production.

[0025] In the preparation method of the present invention, there are two kinds of raw materials that are easy to obtain: 1. Alumina waste catalysts in the petrochemical industry (some varieties contain more than 50% alumina, with an annual output of more than 1,000 tons, most of which cannot be used for landfill treatment); 2. Waste aluminum car scraps in the aluminum alloy processing industry (currently thousands of tons of this kind of waste is only in Shanghai every year, and 2,000 yuan per ton is used for waste treatment,...

Embodiment 1

[0053] Step 1. Preparation of aluminum ammonium sulfate crystal (ammonium alum)

[0054] Use alumina waste catalyst as raw material: grind the waste catalyst into powder, weigh the sample according to the molar ratio of alumina content to ammonium bisulfate as 1:10, add it to molten ammonium bisulfate several times, and react for 1 hour. After cooling, add water to dissolve;

[0055] Alternatively, use scrap aluminum scraps as raw materials: weigh the scrap aluminum scraps according to the molar ratio of aluminum content to ammonium bisulfate as 1:3, add them to the saturated solution of ammonium bisulfate several times as appropriate, and place them overnight (12 hours), let it fully react;

[0056] Filter the solution after the above reaction, take the filtrate, heat and concentrate the filtrate, recrystallize it three times, pulverize it, and dry it at 60°C for 2 hours to obtain aluminum ammonium sulfate crystals.

[0057] Step 2, the preparation of basic ammonium aluminu...

Embodiment 2

[0062] Step 1. Preparation of aluminum ammonium sulfate crystal (ammonium alum)

[0063] Use alumina waste catalyst as raw material: grind the waste catalyst into powder, weigh the sample according to the molar ratio of alumina content to ammonium bisulfate as 1:8, add it to molten ammonium bisulfate several times, and react for 0.5 hours. After cooling, add water to dissolve;

[0064] Alternatively, use scrap aluminum scraps as raw materials: weigh the scrap aluminum scraps according to the aluminum content and ammonium bisulfate molar ratio of 1:3, add them to the saturated solution of ammonium bisulfate several times as appropriate, and place them overnight (8 hours), let it fully react;

[0065] Filter the solution after the above reaction, take the filtrate, heat and concentrate the filtrate, recrystallize it three times, pulverize it, and dry it at 60°C for 2 hours to obtain aluminum ammonium sulfate crystals.

[0066] Step 2, the preparation of basic ammonium aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com