Preparation method of shape-controllable nano silver core/mesoporous silicon dioxide shell structure

A technology of mesoporous silica and nano-silver, applied in the intersection of nano-materials and biotechnology, can solve problems such as affecting catalytic efficiency, and achieve the effects of simple process, cheap and easy-to-obtain raw materials, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

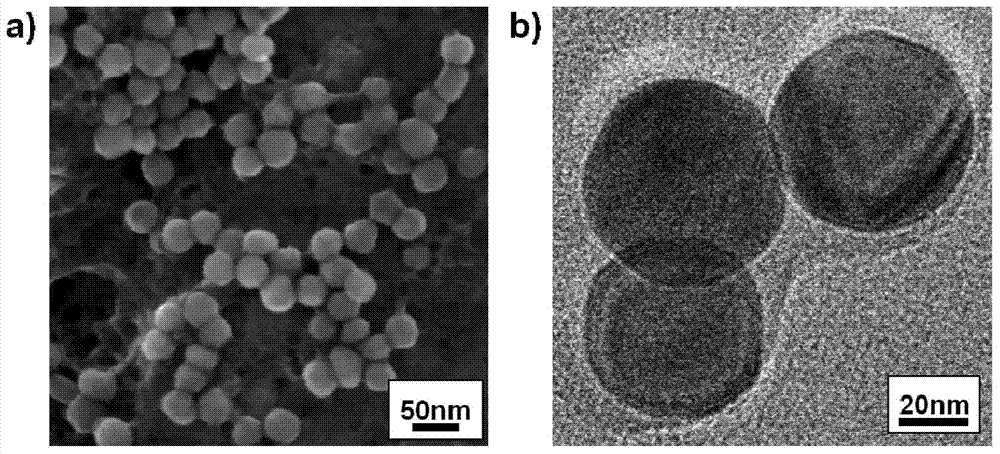

[0031] The present embodiment provides a kind of preparation method of sphere nano-silver core / sphere mesoporous silica shell, and it comprises the steps:

[0032] 1) Prepare spherical nano-silver particles: heat 5-10mL ethylene glycol to 150 degrees Celsius, add 60 microliters of 3mM sodium hydrosulfide solution, add 500 microliters of 3mM hydrochloric acid solution and 20mg / ml polyvinylpyrrolidone solution after 2 minutes 1.25 ml, after 2 minutes, add 400 microliters of 282 mM silver trifluoroacetate solution, keep for 10 minutes, centrifuge after ice bath, wash with acetone and deionized water, and finally disperse in the aqueous solution.

[0033] 2) Surface modification of nano-silver particles: Add 15mL of isopropanol to the above-mentioned aqueous solution of 5ml of deionized water, stirred for 15-30min.

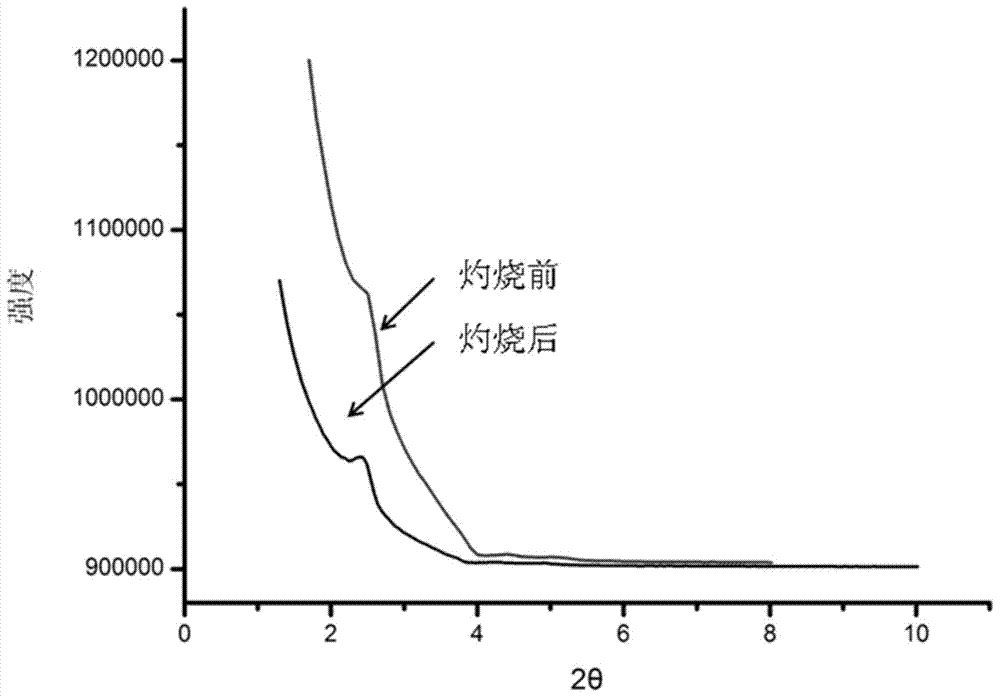

[0034] 3) Preparation of nano-silver core / mesoporous silica shell structure: Stir and add 100 microliters of 0.1mol / L sodium hydroxide solution and 50-100 microliter...

Embodiment 2

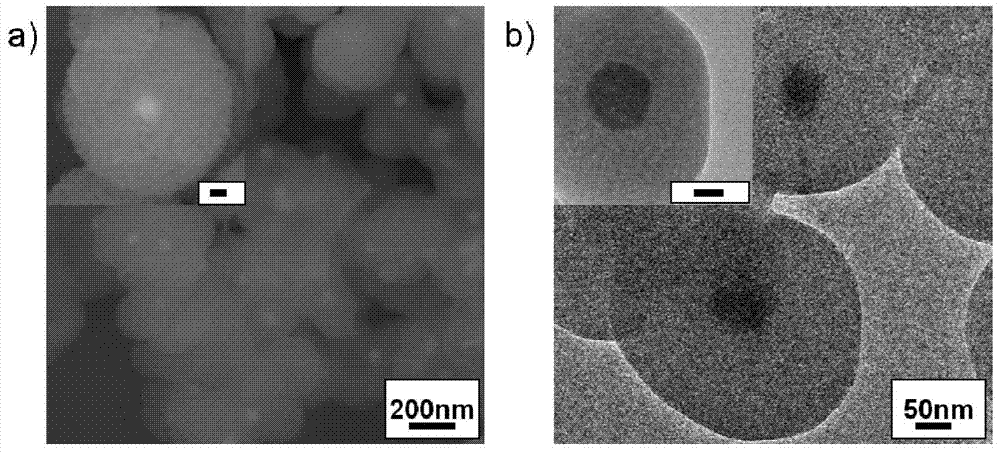

[0040] The present embodiment provides a kind of preparation method of cube nano-silver core / sphere mesoporous silica shell, and it comprises the following steps:

[0041] 1) Preparation of cubic nano-silver particles: heat 5-10mL ethylene glycol to 150 degrees, add 60 microliters of 3mM sodium hydrosulfide solution, add 500 microliters of 3mM hydrochloric acid solution and 20mg / ml polyethylene after 2-3 minutes 1.25 ml of pyrrolidone solution, 400 microliters of 282 mM silver trifluoroacetate solution was added after 2-3 minutes, kept for 20-30 minutes, centrifuged after ice bath, washed with acetone and deionized water, and finally dispersed in aqueous solution.

[0042] 2) Surface modification of nano-silver particles: Add 15 mL of isopropanol to the aqueous solution of nano-silver particles, take 0.3-0.5 g of CTAB powder, add 5 mL of deionized water to the solution, and stir for 15-30 min.

[0043] 3) Preparation of nano-silver core / mesoporous silica core-shell structure: ...

Embodiment 3

[0049] The present embodiment provides a kind of preparation method of cubic nano-silver core / cubic mesoporous silica shell, and it comprises the following steps:

[0050] 1) Preparation of cubic nano-silver particles: heat 5-10mL ethylene glycol to 150 degrees Celsius, add 60 microliters of 3mM sodium hydrosulfide solution, add 500 microliters of 3mM hydrochloric acid solution and 20mg / ml polyethylene after 2-3 minutes 1.25 ml of pyrrolidone solution, 400 microliters of 282 mM silver trifluoroacetate solution was added after 2-3 minutes, kept for 20-30 minutes, centrifuged after ice bath, washed with acetone and deionized water, and finally dispersed in aqueous solution.

[0051] 2) Surface modification of nano-silver particles: Add 15 mL of isopropanol to the aqueous solution of nano-silver particles, add 0.1-0.2 g of CTAB powder into the solution, then add 5 mL of deionized water, and sonicate for 1-20 min.

[0052] 3) Preparation of nano-silver core / mesoporous silica shell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com