Liquid crystal alignment agent containing both polyamic acid ester and polyamic acid

A liquid crystal aligning agent, polyamic acid ester technology, applied in coatings, instruments, optics, etc., can solve the problems of unknown residual charge relaxation characteristics, slow residual charge relaxation, and high volume resistivity, achieving excellent electrical characteristics, Effects of improved liquid crystal alignment and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

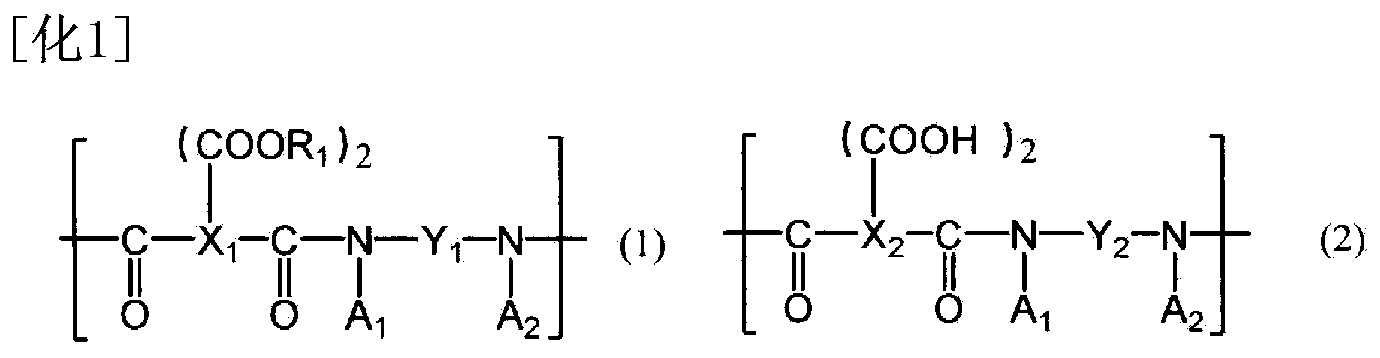

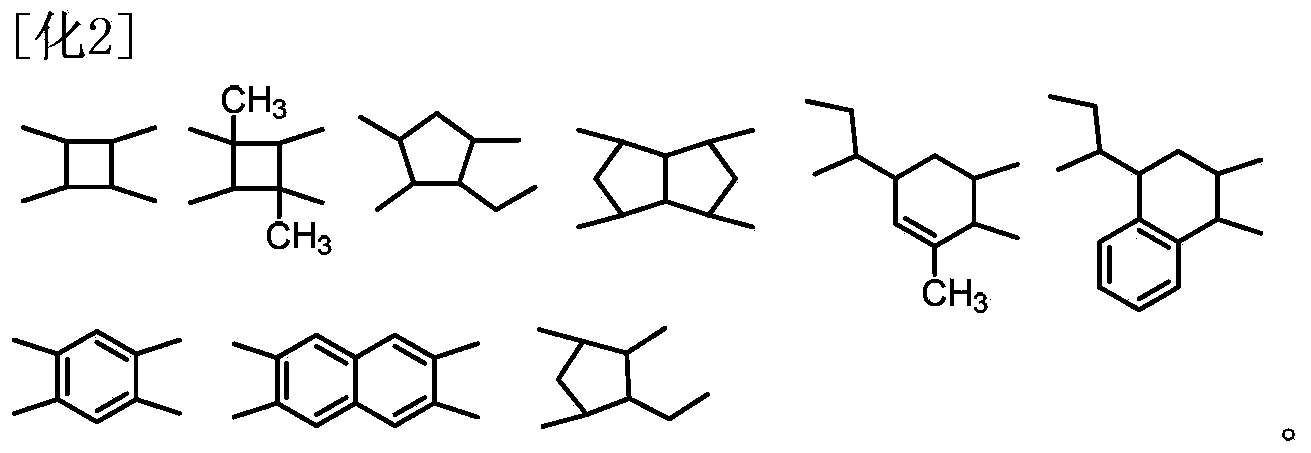

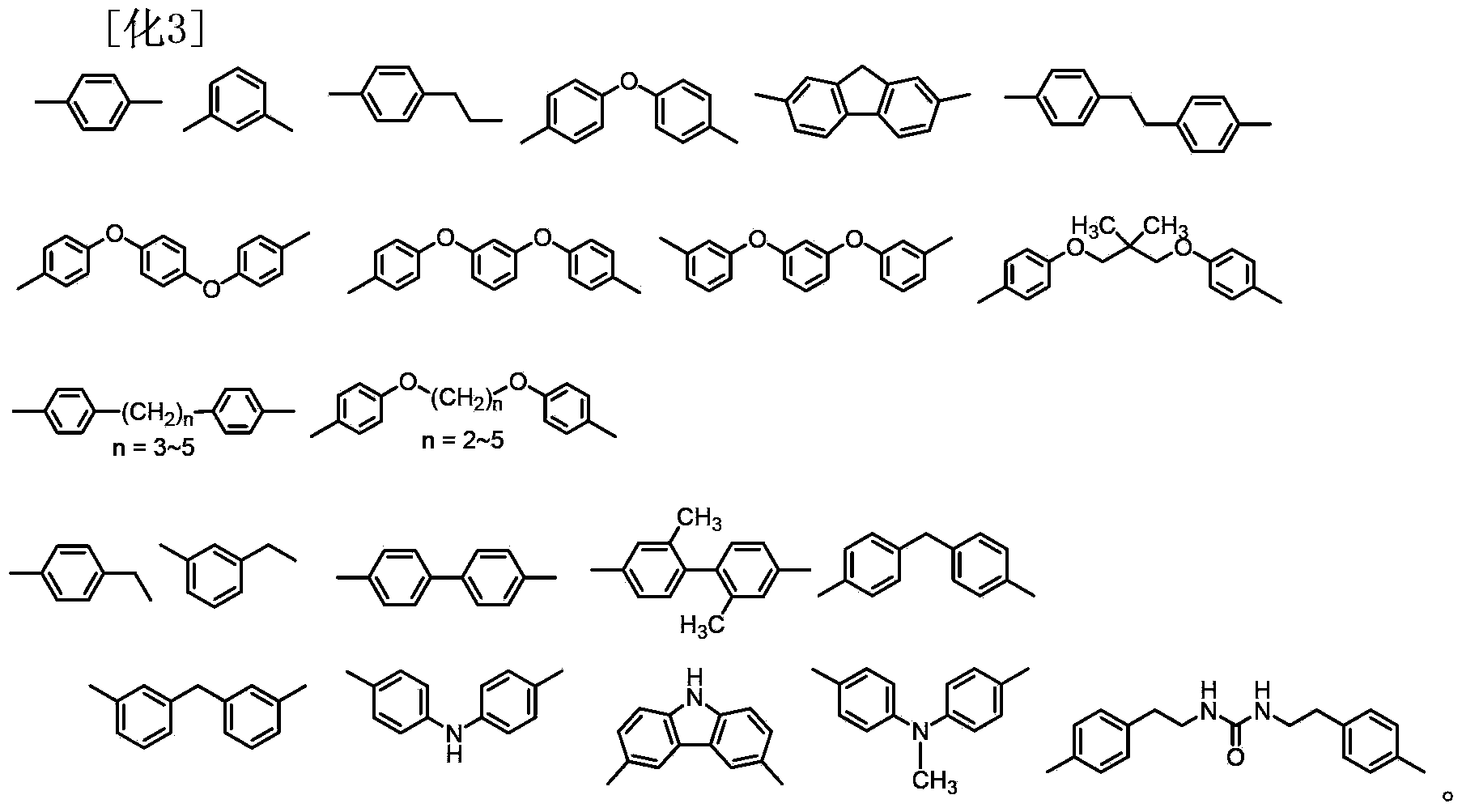

[0137] The abbreviations and structures of the compounds used in this synthesis example are shown below.

[0138] DMT-MM: 4-(4,6-Dimethoxy-1,3,5-triazin-2-yl)-4-methylmorpholine chloride

[0139] CBDE: 2,4-bis(methoxycarbonyl)cyclobutane-1,3-dicarboxylic acid

[0140] PMDE: 2,5-bis(methoxycarbonyl)benzene-1,4-dicarboxylic acid

[0141] CBDA: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0142] PMDA: pyromellitic dianhydride

[0143] DDE: 4,4'-diaminodiphenyl ether

[0144] DA-3MG: 1,3-bis(4-aminophenoxy)propane

[0145] DA-5MG: 1,5-bis(4-aminophenoxy)pentane

[0146] BAPU: 1,3-bis(4-aminophenethyl)urea

[0147] Me-DADPA: 4,4'-Diaminodiphenylmethylamine

[0148]

[0149]

[0150] Each measuring method of viscosity, solid content concentration, and average surface roughness is shown below.

[0151] [Viscosity]

[0152] In the synthesis example, the viscosity of the polyamic acid solution or the polyamic acid ester solution was measured using an E-type viscome...

Synthetic example 1

[0167]8.47 g (30 mmol) of PMDE and 17.2 g (66 mmol) of CBDE were weighed into a 1 L (liter) separable flask to which a stirring bar was added, and 684 g of N-methyl-2-pyrrolidone was added and dissolved by stirring. Next, 5.06 g (50 mmol) of triethylamine and 25.8 g (100 mmol) of DA-3MG were added and dissolved by stirring. While stirring this solution, 83.0 g (300 mmol) of DMT-MM (15±2 wt % hydrate) was added, and 122 g of N-methyl-2-pyrrolidone was added, and the solution was stirred at room temperature for 5 hours to obtain a polyamic acid ester. solution. The viscosity of the polyamic acid ester solution at a temperature of 25°C was 32.3 mPa·s.

[0168] This polyamic acid ester solution was injected|thrown-in to methanol (5676g), and the obtained precipitate was isolate|separated by filtration. The precipitate was washed with methanol, and then dried under reduced pressure at a temperature of 100°C to obtain a polyamic acid ester powder.

[0169] 4.03 g of this polyamic...

Synthetic example 2

[0171] In a 200 mL four-necked flask to which a stirring bar was added, 2.68 g (9.5 mmol) of PMDE was weighed, 70 g of N-methyl-2-pyrrolidone was added, and the mixture was stirred and dissolved. Next, 0.51 g (5 mmol) of triethylamine and 2.58 g (10 mmol) of DA-3MG were added and dissolved by stirring. While stirring this solution, 9.96 g (36 mmol) of DMT-MM (15±2 wt % hydrate) was added, and 13 g of N-methyl-2-pyrrolidone was added, and the solution was stirred at room temperature for 4 hours to obtain polyamic acid ester. solution. The viscosity of the polyamic acid ester solution at a temperature of 25°C was 35.9 mPa·s.

[0172] The polyamic acid ester solution was put into methanol (589 g), and the obtained precipitate was separated by filtration. The precipitate was washed with methanol, and then dried under reduced pressure at a temperature of 100°C to obtain a polyamic acid ester powder.

[0173] 2.23 g of this polyamic acid ester powder was weighed in a 50 mL Erlenm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com