Lithium-ion battery gel electrolyte and its monomer, its preparation method and preparation method of lithium-ion battery

A gel electrolyte, lithium ion battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problem of graphite carbon negative electrode compatibility needs to be improved, etc., to achieve easy mass production, enhance sports ability , the effect of reducing the presence of free solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

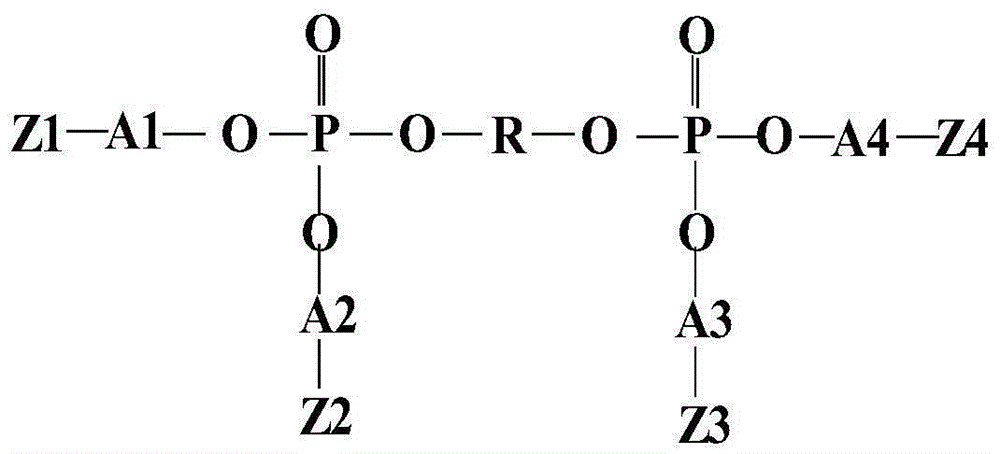

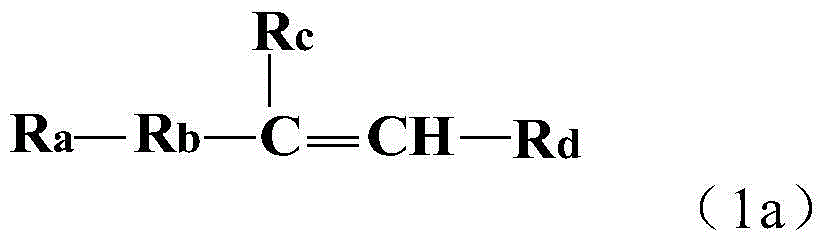

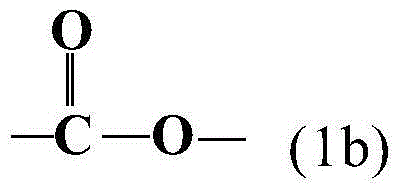

[0031] According to the preparation method of the monomer for lithium ion battery gel electrolyte according to the second aspect of the present invention, it prepares the monomer for lithium ion battery gel electrolyte according to the first aspect of the present invention, comprising the steps of: adding phosphorus oxychloride Dissolved in an organic solvent; adding at least one of dibasic alcohol, dibasic epoxy or diglycidyl ether; optionally adding the corresponding catalyst triphenylphosphine when dibasic epoxy is selected; adding alkenyl The esters react with the acid-binding agent triethylamine in the reflux state of the organic solvent to obtain a monomer for lithium-ion battery gel electrolyte.

[0032] In the above steps, the order of adding at least one of dibasic alcohol, dibasic epoxy or diglycidyl ether and adding alkenyl esters and acid-binding agent triethylamine can be reversed.

[0033] In the preparation method of the monomer for lithium ion battery gel electro...

Embodiment A

[0053] Add 40ml of ethyl acetate and 0.4mol of phosphorus oxychloride into a 250ml three-necked flask and stir to dissolve;

[0054] Slowly add 0.2mol of 1,3-propanediol dropwise into a 250ml three-necked flask at 15°C, and react at constant temperature for 1h;

[0055] At room temperature, add 1 mol of triethylamine and 0.8 mol of hydroxyethyl acrylate into a 250ml three-necked flask, raise the temperature to 50°C, and react at a constant temperature for 10 hours;

[0056] After extraction, washing with water, filtration, vacuum distillation at 70°C and 850MPa, and drying, a light yellow oily product was obtained with a yield of 90%.

[0057] The structural formula of the lithium-ion battery gel electrolyte monomer prepared by embodiment A is as follows:

[0058]

[0059] The monomer with the above structural formula is named tetrakis (acryloyloxyethyl) propylene glycol bisphosphate, TABP for short.

Embodiment B

[0061] Add 40ml toluene and 0.4mol phosphorus oxychloride to a 250ml three-necked flask and stir to dissolve;

[0062] Mix 1 mol of triethylamine and 0.8 mol of hydroxyethyl acrylate, drop them into a three-necked flask at room temperature, and react at 35°C for 5 hours;

[0063] Add 0.18mol of epoxy resin E51 (its relative molecular mass is 392) into a 250ml three-necked flask, heat up to 50°C, and stir at constant temperature for 1h;

[0064] The catalyst triphenylphosphine was added into a 250ml three-necked flask, and the temperature was raised to 80°C for a constant temperature reaction for 2 hours. After the reaction was completed, the pure product was obtained by filtering, washing, and drying with a yield of 80%.

[0065] The structural formula of the lithium ion battery gel electrolyte monomer that embodiment B makes is as follows:

[0066]

[0067] Where n=1, the monomer having the above structural formula is named tetrakis(acryloyloxyethyl)bisphenol A bisphospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com