Preparation method and application of hollow tin alloy nanoparticles with a particle size of less than 50 nm

A nanoparticle, tin alloy technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of active material pulverization, poor cycle performance, capacity reduction, etc., and achieve uniform particle size. , the effect of easy experimental conditions and simple experimental methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

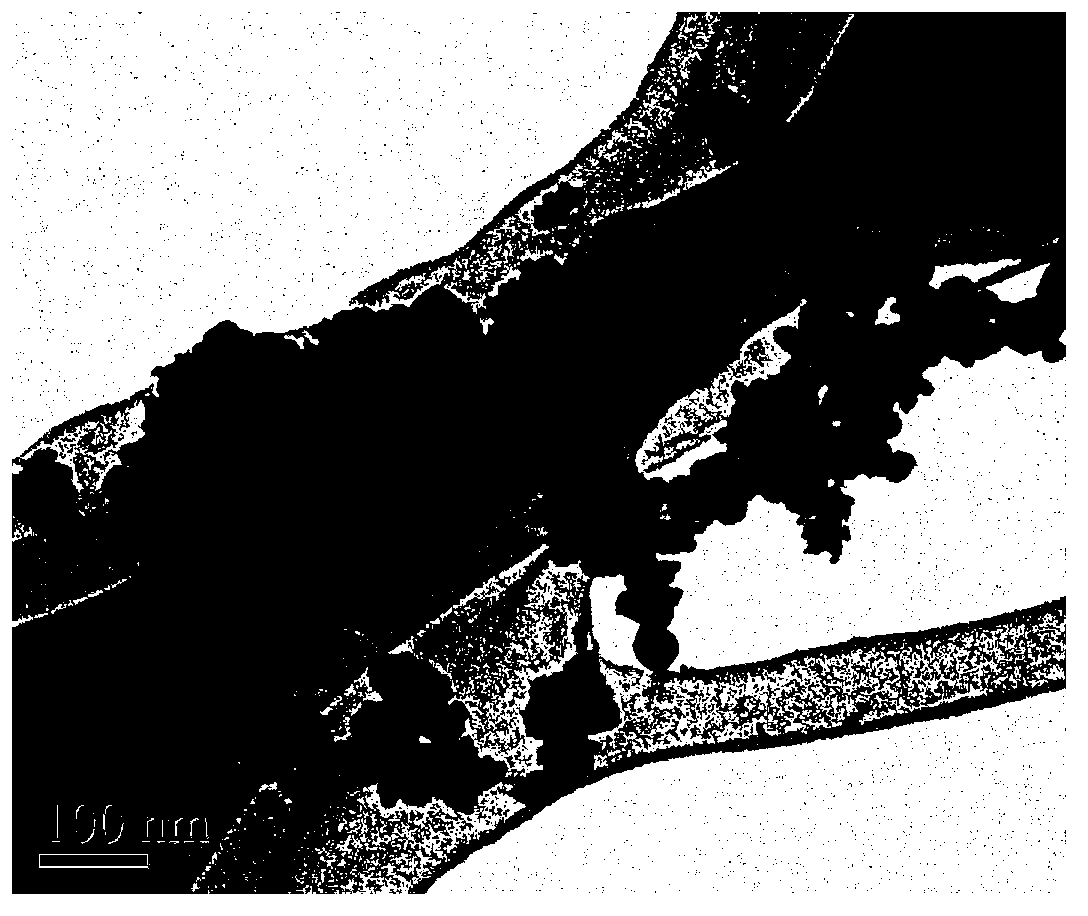

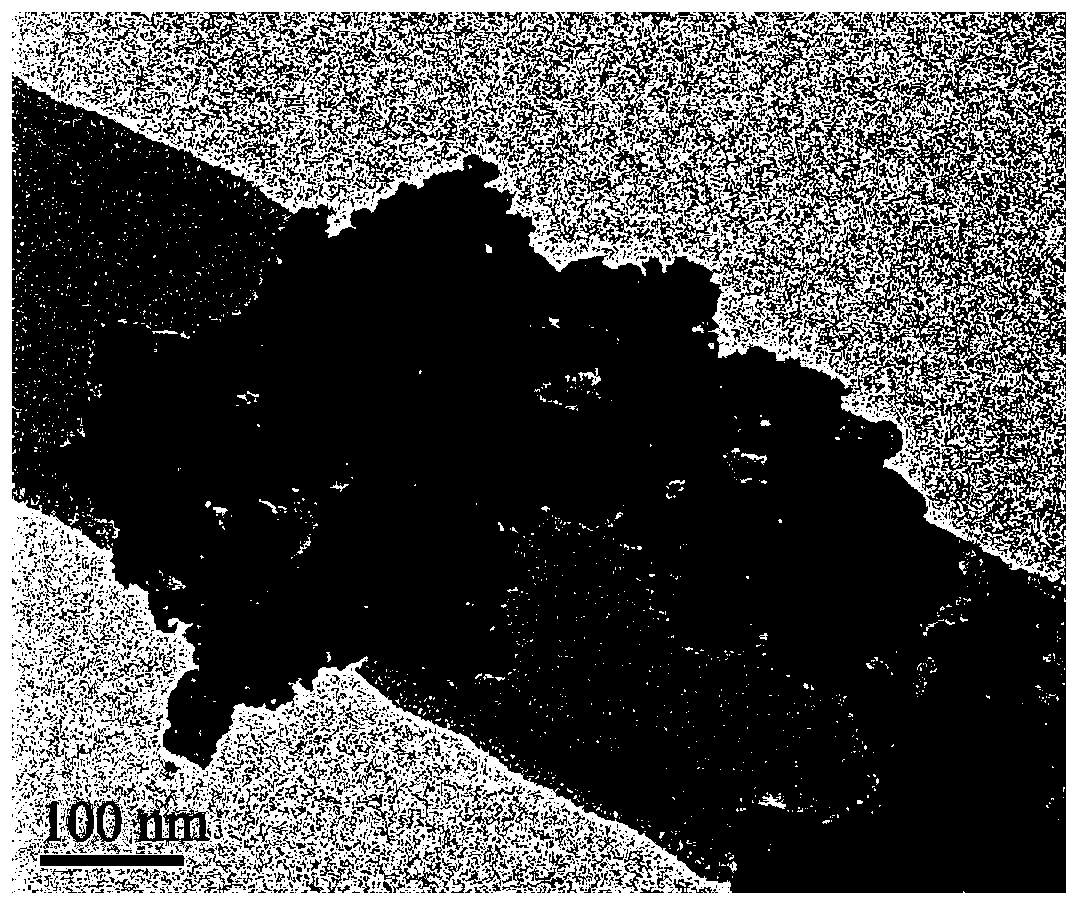

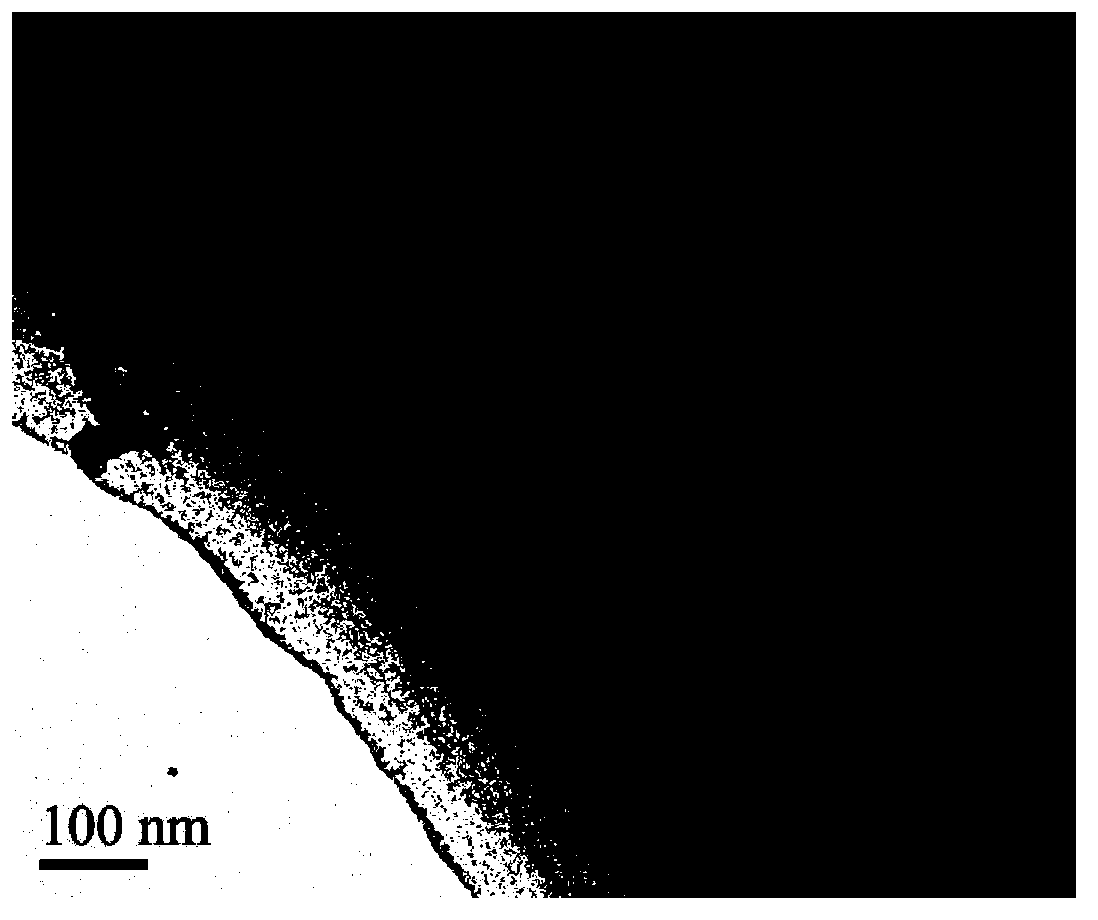

Image

Examples

Embodiment 1

[0024] 1) Measure 40ml of deionized water in a beaker, add 0.4g of concentrated sulfuric acid into it, stir to form a 0.01g / ml dilute sulfuric acid aqueous solution, then weigh stannous sulfate (SnSO 4 ) 0.4g, polyvinylpyrrolidone (PVP) 0.04g were added to dilute sulfuric acid solution, stirred and dissolved to form solution A, in which SnSO 4 and PVP concentrations were 0.01g / ml and 0.001g / ml;

[0025] 2) Measure 160ml of deionized water in a beaker, weigh 0.32g of sodium borohydride (NaBH 4 ) into it, stirred and dissolved to form a 0.002g / ml sodium borohydride aqueous solution, weighed 0.5g sodium hydroxide and dissolved in 40ml deionized water, dissolved to form a sodium hydroxide solution, and added the solution to the sodium borohydride solution, Adjust pH≧12 to obtain solution B;

[0026] 3) Add solution A to solution B drop by drop under stirring at room temperature, and react for about 3 hours until no bubbles are generated. After the reaction is finished, the solu...

Embodiment 2

[0031] 1) Measure 40ml of deionized water in a beaker, add 0.8g of concentrated sulfuric acid into it, stir to form a 0.02g / ml dilute sulfuric acid aqueous solution, then weigh stannous sulfate (SnSO 4 ) 0.8g, polyvinylpyrrolidone (PVP) 0.06g were added to dilute sulfuric acid solution, stirred and dissolved to form solution A, in which SnSO 4 and PVP concentrations were 0.02g / ml and 0.0015g / ml;

[0032] 2) Measure 160ml of deionized water in a beaker, weigh 0.64g of sodium borohydride (NaBH 4 ) into it, stirred and dissolved to form a 0.004g / ml sodium borohydride aqueous solution, weighed 0.5g sodium hydroxide and dissolved in 40ml deionized water, dissolved to form a sodium hydroxide solution, and added the solution to the sodium borohydride solution, Adjust pH≧12 to obtain solution B;

[0033] 3) Add solution A to solution B drop by drop under stirring at room temperature, and react for about 3 hours until no bubbles are generated. After the reaction is finished, the sol...

Embodiment 3

[0038] 1) Measure 40ml of deionized water in a beaker, add 1.2g of concentrated sulfuric acid into it, stir to form a 0.03g / ml dilute sulfuric acid aqueous solution, and then weigh stannous sulfate (SnSO 4 ) 1.2g, polyvinylpyrrolidone (PVP) 0.08g were added to the dilute sulfuric acid solution, stirred and dissolved to form solution A, in which SnSO 4 and PVP concentrations were 0.03g / ml and 0.002g / ml;

[0039] 2) Measure 160ml of deionized water in a beaker, weigh 0.96g of sodium borohydride (NaBH 4 ) into it, stirred and dissolved to form a 0.006g / ml sodium borohydride aqueous solution, weighed 0.5g sodium hydroxide and dissolved in 40ml deionized water, dissolved to form a sodium hydroxide solution, and added the solution to the sodium borohydride solution, Adjust pH≧12 to obtain solution B;

[0040] 3) Add solution A to solution B drop by drop under stirring at room temperature, and react for about 3 hours until no bubbles are generated. After the reaction is finished, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com