Composite method for modifying flax fabric via crystal lattice change

A linen fabric and composite crystal technology, which is applied in the processing of textile materials, plant fibers, textiles and papermaking, can solve problems such as unevenness, reduced crystallinity, and inconspicuousness, and achieve excellent softness and improved dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

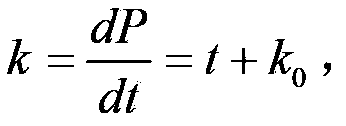

[0026] A compound crystal transformation modification method of flax fabrics, the flax fabrics of 5 × 5, 250 strands / 10cm × 100 strands / 10cm are placed in a closed container, filled with liquid ammonia, and boosted in a linear boosting manner, The boost rate k satisfies the relation Initial boost rate k 0 0.5MPa / min, pressurize to 1Mpa modified pressure, keep the pressure for 1min, and release to 0.005Mpa within 5 seconds at a depressurization rate of 2MPa / s. Finally, the modified medium in the flax fabric was removed by high-speed centrifugal spin dehydration, microwave heating and vacuuming in parallel to obtain the composite crystal-modified flax fabric. Among them, the high-speed centrifugal rotation speed reaches 120rpm, the rotation time can reach 10min, and the radial draft reaches 1.2mm; the power of a single modification kettle in microwave heating is 1kW; the vacuum is pumped to negative pressure and below. Compared with the microscopic lattice of the linen fabric...

Embodiment 2

[0028] A compound crystal transformation modification method of flax fabrics, the linen fabrics of 30 pieces × 36 pieces, 218 pieces / 10cm×196 pieces / 10cm are placed in a closed container, filled with liquid ammonia, and the pressure is boosted in a linear boosting manner, The boost rate k satisfies the relation Initial boost rate k 0 0.8MPa / min, pressurize to 1.5Mpa for modified pressure, keep the pressure for 5min, and release to 0.0015Mpa within 5 seconds at a depressurization rate of 3MPa / s. Finally, the modified medium in the flax fabric was removed by high-speed centrifugal spin dehydration, microwave heating and vacuuming in parallel to obtain the composite crystal-modified flax fabric. Among them, the high-speed centrifugal rotation speed reaches 150rpm, the rotation time can reach 10min, and the radial draft can reach 2mm; the power of a single modified kettle in microwave heating is 5kW; the vacuum is pumped to negative pressure and below. Compared with the microsc...

Embodiment 3

[0030] A compound crystal transformation modification method of flax fabrics, the linen fabrics of 21 pieces × 36 pieces, 236 pieces / 10cm×190 pieces / 10cm are placed in a closed container, filled with liquid ammonia, and the pressure is boosted in a linear boosting manner, The boost rate k satisfies the relation Initial boost rate k 0 The pressure is 0.8MPa / min, boosted to a modified pressure of 1.5Mpa, maintained for 5 minutes, and then released to 0.0015Mpa instantaneously within 4 seconds at a depressurization rate of 3MPa / s. Finally, the modified medium in the flax fabric was removed by high-speed centrifugal spin dehydration, microwave heating and vacuuming in parallel to obtain the composite crystal-modified flax fabric. Among them, the high-speed centrifugal rotation speed reaches 150rpm, the rotation time can reach 10min, and the radial draft can reach 2mm; the power of a single modified kettle in microwave heating is 10kW; the vacuum is pumped to negative pressure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com