Direct reduced iron water cooling cylinder device

A reduced iron, direct technology, applied in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of increased useless water, short contact time, and large water consumption in the system, so as to reduce the degree of line of sight barrier and improve heat exchange Time, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

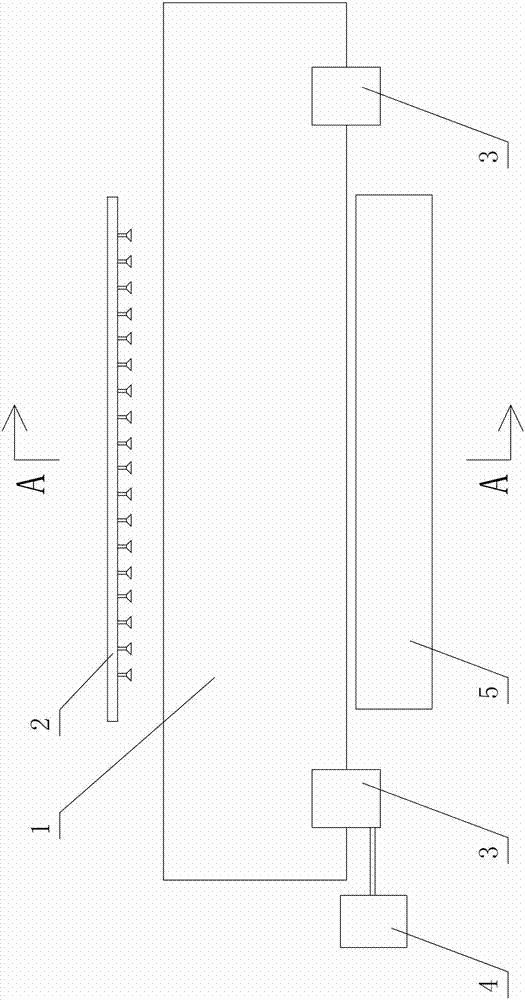

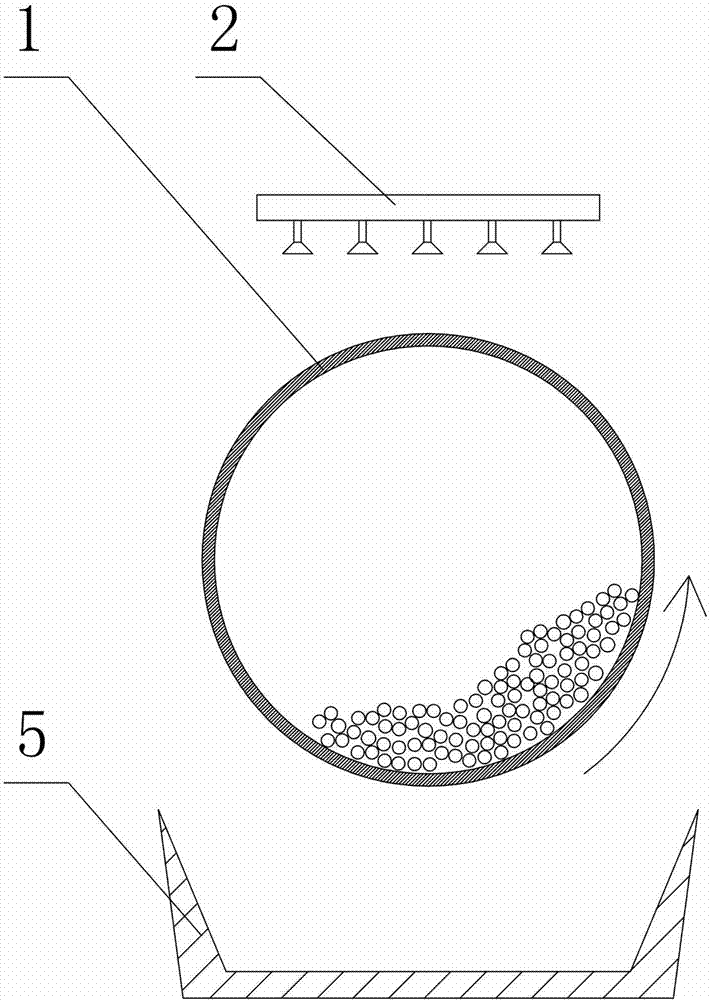

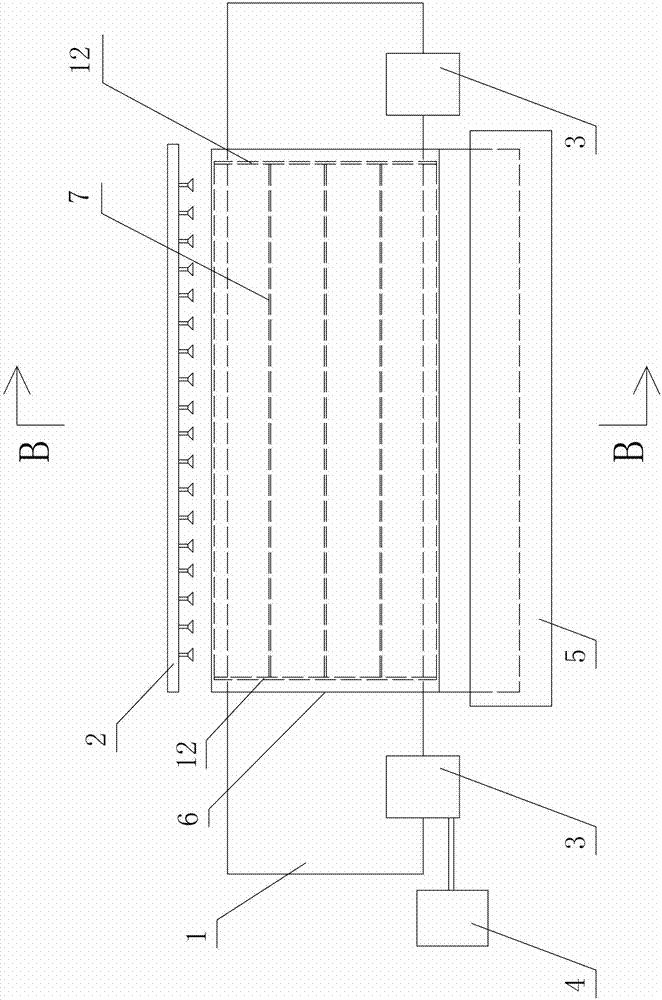

[0035] Figure 3 to Figure 5 An embodiment of the direct reduced iron water-cooled cylinder device of the present invention is shown, the device includes a cooling cylinder 1 containing materials and a water spray assembly 2, and the water spray assembly 2 includes a plurality of showers arranged above the cooling cylinder 1, Used to spray cooling water to the outer wall of the cooling cylinder 1. The cooling cylinder 1 is in the shape of a horizontal cylinder, driven to rotate by the driving assembly, so that the circumferential outer wall of the cooling cylinder 1 is cooled by cooling water; the driving assembly includes the idler mechanism 3 supported on the bottom of the cooling cylinder 1 and the idler mechanism 3 connected rotary drive mechanism 4 (such as a motor). A cover tube 6 is sleeved on the outside of the cooling tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com