High-heat-insulation, ultraviolet-isolation and transparent colored master batch and preparation method thereof

An ultraviolet and masterbatch technology, applied in the field of high heat insulation ultraviolet shielding transparent colored masterbatch and its preparation, can solve the problems of difficult adhesion of PET materials, many impurities in coating process particles, uneven color, etc., and achieve uniform color, The effect of good smoothness and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

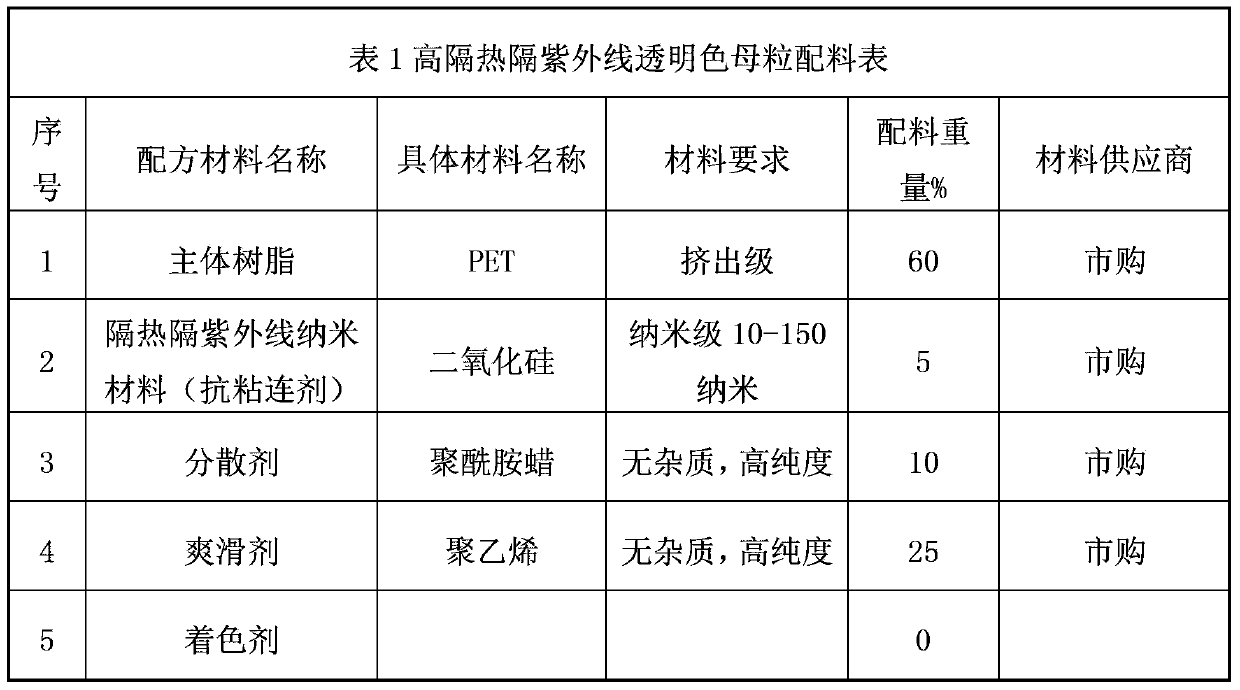

[0023] Embodiment 1: See Table 1 for masterbatch ingredients.

[0024]

[0025] 1) Under normal temperature and pressure, in the high-speed mixer, turn on the stirring paddle and control the rotation speed to 600r / min, and the heating and mixing temperature is 85°C;

[0026] 2) After weighing the materials as stated in the ingredient list, first put in 50% of the total amount of PET resin, and then put in other components according to the proportion of ingredients, and wait for the materials to be mixed for 10 minutes to ensure that the slip agent has completely melted and the materials are formed into knots. block, add the rest of the PET resin after cooling;

[0027] 3) Then control the speed of the mixer to 480r / min to disperse the material into granules to complete the initial melting and mixing of the material, and the dispersing time is 1h;

[0028] 4) Put the pre-melted and mixed materials into the twin-screw machine for further melt blending. The melting temperatur...

Embodiment 2

[0030] Embodiment 2: See Table 2 for masterbatch ingredients.

[0031]

[0032] 1) Under normal temperature and pressure, in the high-speed mixer, turn on the stirring paddle and control the rotation speed to 1000r / min, and the heating and mixing temperature is 100°C;

[0033] 2) After weighing the materials according to the ingredients list, first put in 50% of the total amount of PET resin, and then put in other components according to the proportion of ingredients, and wait for the materials to be mixed for 15 minutes to ensure that the slip agent has completely melted and the materials are formed into knots. block, add the rest of the PET resin after cooling;

[0034] 3) Then control the speed of the mixer to 250r / min to disperse the material into granules to complete the initial melting and mixing of the material, and the dispersing time is 10h;

[0035] 4) Put the preliminarily melted and mixed materials into a twin-screw machine for further melt blending. The meltin...

Embodiment 3

[0037] Embodiment 3: See Table 3 for masterbatch ingredients.

[0038]

[0039] 1) Under normal temperature and pressure, in the high-speed mixer, turn on the stirring paddle and control the rotation speed to 800r / min, and the heating and mixing temperature is 95°C;

[0040] 2) After weighing the materials according to the ingredient list, first put in 50% of the total amount of PET resin, and then put in other components according to the proportion of ingredients, and wait for the materials to mix for 25 minutes to ensure that the slip agent has completely melted and the materials are formed into knots. block, add the rest of the PET resin after cooling;

[0041] 3) Control the speed of the mixer to 500r / min to disperse the material into granules to complete the initial melting and mixing of the material, and the dispersing time is 5 hours;

[0042] 4) Put the pre-melted and mixed materials into a twin-screw machine for further melt-blending. The melting temperature is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com