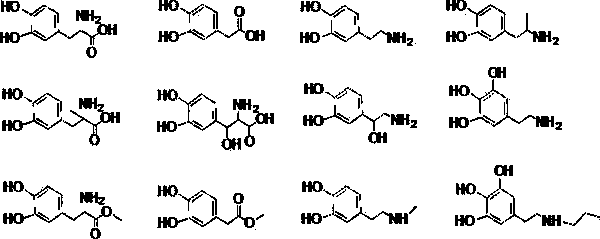

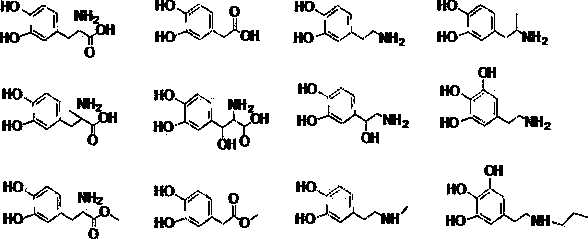

Nanometer functionalization surface modification method based on o-dihydroxybenzene derivatives

A surface modification, nano-functional technology, applied in chemical instruments and methods, material electrochemical variables, coatings, etc., to achieve the effect of strong universality, easy industrialization, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0026] Soak the plastic monolith in 0.2 mmol / L borate buffer solution (pH7.4), then add 3,4-dihydroxyphenylacetic acid at a concentration of 0.05 mg / mL, and add ammonium persulfate (0.5 mg / mL ). Stir or shake the solution continuously for 7 days, take out the single piece, and wash it repeatedly with 50% ethanol aqueous solution to remove unreacted 3,4-dihydroxyphenylacetic acid and unattached poly-3,4-dihydroxyphenylacetic acid. Then the poly-3,4-dihydroxyphenylacetic acid-coated plastic monolithic sheet was soaked in different concentrations of copper nanoparticle solutions (0.001 mMol / L, 1 mMol / L, 100 mMol / L, 500 mMol / L, 1 Mol / L L) After 24 hours (at room temperature), after cleaning the excess saline solution, let the plastic single piece dry naturally, and test the conductivity. The results show that a good conductive layer is formed on the non-conductive plastic monolithic surface after the growth of copper nanoparticles, and plastic electroplating parts can be formed o...

Embodiment 6-9

[0028] Soak the glassy carbon electrode in 1 mmol / L phosphate buffer solution (pH7.0), then add 3,4-dihydroxybenzylamine at a concentration of 100 mg / mL, and add sodium periodate (0.5mg / mL). Stir or shake the solution continuously for 5 minutes, take out the electrode, and wash it repeatedly with 50% ethanol aqueous solution to remove unreacted 3,4-dihydroxybenzylamine and unattached poly-3,4-dihydroxybenzylamine. Then soak the glassy carbon electrode coated with poly-3,4-dihydroxybenzylamine in different concentrations of polyaminopyridine solutions (51 mMol / L, 100 mMol / L, 500 mMol / L, 1 Mol / L) 24 hours (room temperature), followed by treatment to activate the electrode and test the electrochemical behavior of caffeine on the electrode. The results show that the electrode has a good electrocatalytic ability for the electrooxidation reaction of caffeine, and the oxidation peak potential difference increases, so that the motor can achieve a good detection effect.

Embodiment 10

[0030] The forward osmosis membrane was soaked in 10 mmol / L Tris(TRIS) hydrochloric acid buffer solution (pH 8.5), and then 3,4-dihydroxyphenylacetic acid (DOPAC) was added at a concentration of 2 mg / mL. Stir or shake the solution continuously for 1 hour, take out the forward osmosis membrane, and wash it repeatedly with pure water to remove unreacted DOPAC and unattached poly-DOPAC. Then the forward osmosis membrane coated with poly-DOPAC was soaked in the silver nanosol with a concentration of 100 mMol / L for 10 hours (room temperature), and then the excess salt solution was washed. Antibacterial experiments have found that the forward osmosis membrane produced by silver nanoparticles has an antibacterial effect of 100% against various bacteria, including Escherichia coli and streptococcus. The forward osmosis membrane produced by silver nanoparticles has an efficiency of 100% in the attachment and growth inhibition of Escherichia coli.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com