High-sensitivity non-enzymatic glucose electrochemical sensor and production method thereof

An electrochemical and glucose technology, applied in the direction of electrochemical variables of materials, can solve the problems of high detection limit and low sensitivity of electrochemical sensors, and achieve the effects of simple process, simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of NiONPs-CNFs

[0029] A. Weigh 0.01g of solid carbon nanofibers (30-100nm in diameter and 2-10μm in length) and add to the solution containing 0.127g NiCl 2 ·6H 2 O solution, ultrasonically stirred until uniform;

[0030] B. While stirring, use 5% (solute mass fraction) ammonia water to adjust the pH of the above solution to 11, and then stir for 3 hours;

[0031] C. Filtrate, wash, dry, and incubate at 300° C. for 2 hours to obtain NiONPs-CNFs.

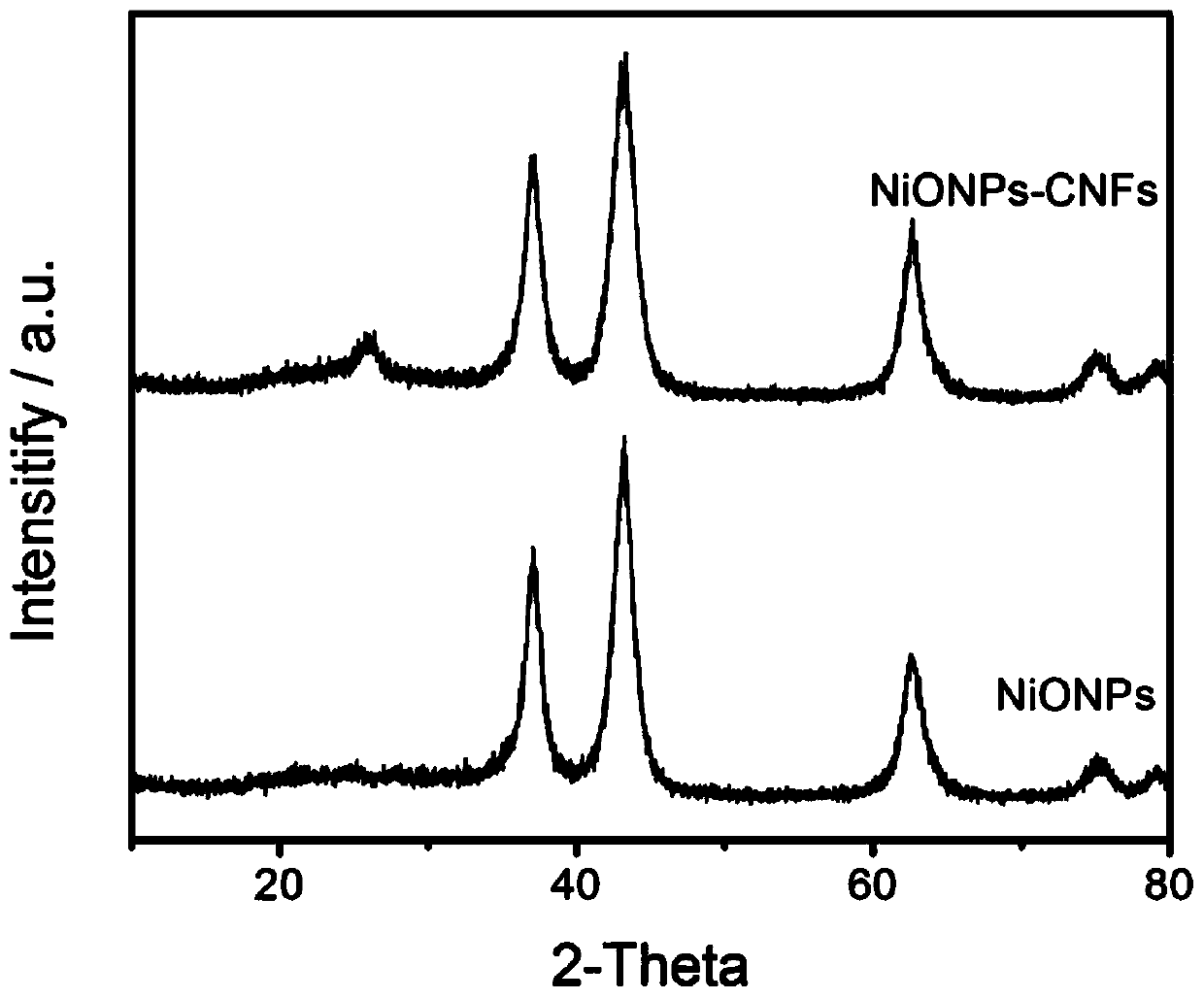

[0032] figure 1 It is the XRD pattern of NiONPs and NiONPs-CNFs prepared in this example. It can be seen from the figure that a strong diffraction peak appears at 25°, which is the (002) plane of CNFs with hexagonal crystal structure. According to the standard spectrum of NiONPs and the literature "Synthesis of CuONiO core-shell nanoparticles by homogeneous precipitation method", it shows that NiONPs-CNFs composites were successfully synthesized.

Embodiment 2

[0034] Preparation of High Sensitivity Glucose Sensor

[0035] A glassy carbon electrode with a diameter of 3 mm was used as the base electrode, and Al at 0.3 μm and 0.5 μm 2 o 3 After the polishing powder is polished to a mirror surface, it is ultrasonically washed with 1:1 nitric acid, ethanol and deionized water for 3 minutes.

[0036] The NiONPs-CNFs prepared in Example 1 were dispersed in DMF solvent with a concentration of 4 mg mL -1 , sonicate for 30 minutes, take 2 μL with a micro-sampler, drop-coat it on the surface of the above-mentioned glassy carbon electrode that has been treated, dry it at room temperature, put the electrode into 0.2M NaOH solution, and use cyclic voltammetry At a scan rate of 100 mV / s, it was activated for 15 cycles, thereby preparing the glucose electrochemical sensor.

Embodiment 3

[0038] Detection experiment

[0039] The detection experiment was carried out on a CHI411A electrochemical workstation and a three-electrode system. The reference electrode was a saturated calomel electrode, the counter electrode was a platinum wire electrode, and the working electrode was the electrochemical sensor prepared in Example 2 of the present invention. The solution is the bottom liquid, and at 0.45V, the time-current curves obtained by adding different concentrations of glucose are as follows: figure 2 as shown,

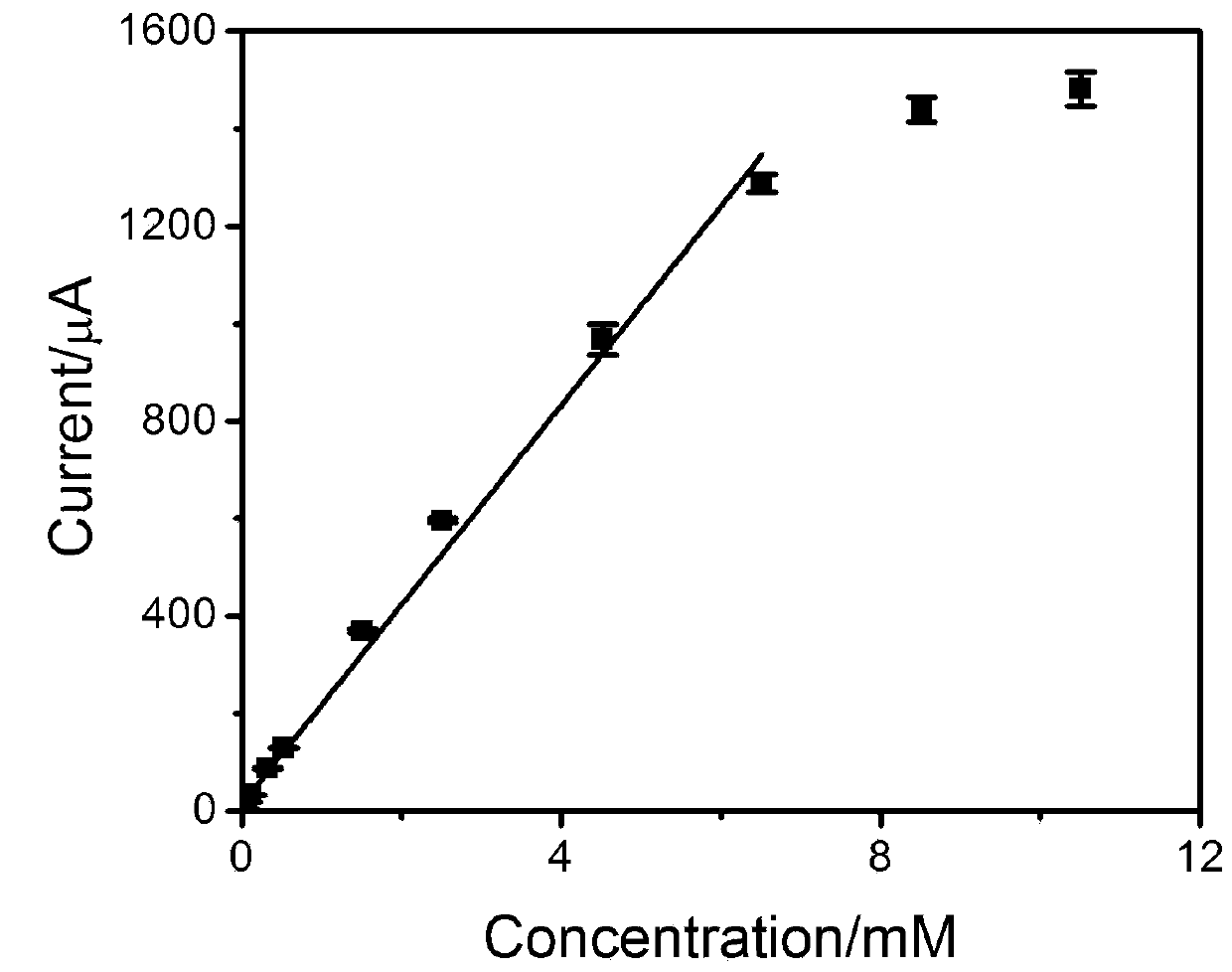

[0040] The linear range of this glucose electrochemical sensor can be derived (as image 3 shown) is 0.5μM~6.5mM, the sensitivity is as high as 2891.7μA mM -1 cm -2 , the linear correlation is very good, R=0.997, and the detection limit is as low as 0.2μM.

[0041] So far, the technology similar to the present invention, such as: A highly sensitive nonenzymatic glucose sensor based on NiO-modified multi-walled carbon nanotubes, the linear range is 2μM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Linear range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com