Salt lake brine evaporation method and equipment thereof, and salt lake brine treatment method by utilizing salt lake brine evaporation method and device thereof

A salt lake brine and treatment method technology, applied in the directions of alkali metal chloride, energy input, etc., can solve the problems of long production cycle, disconnected production process in salt fields, and inability to guarantee the processing process of brine production, so as to improve production efficiency and product yield. The effect of improving the efficiency of halogenation, evaporation rate and brine production, shortening the period of halogenation and salt production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

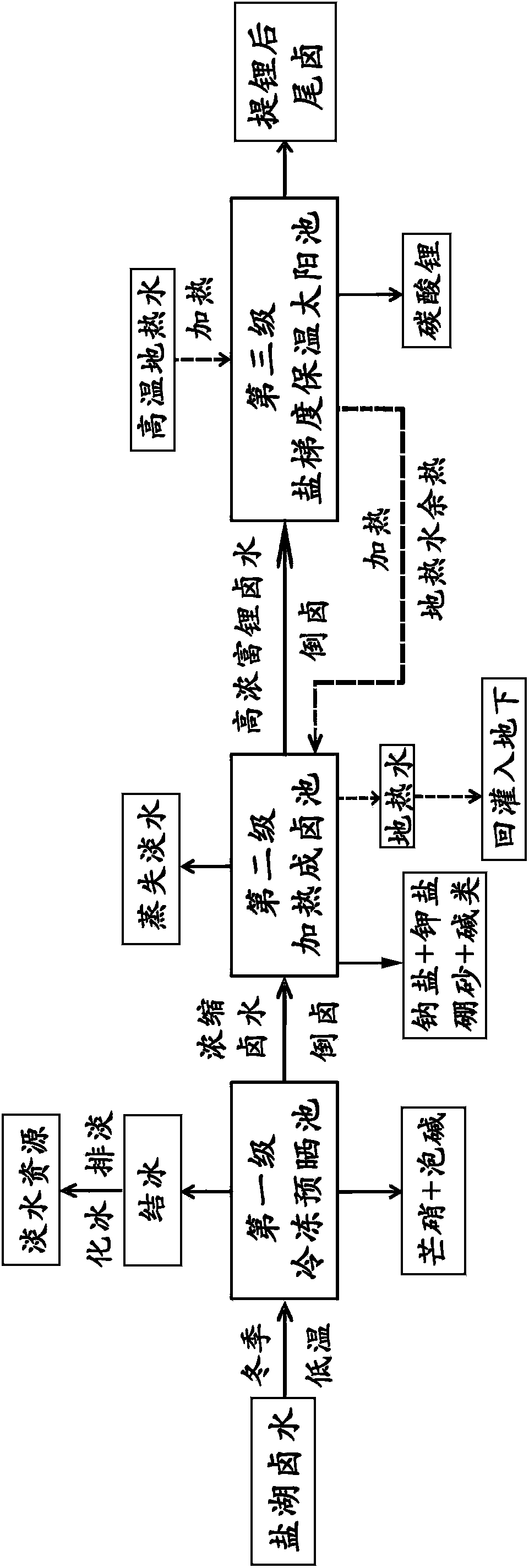

[0068] As a preferred embodiment of the present invention, it is a salt lake brine evaporation method and equipment, such as figure 1 As shown, the method includes:

[0069] Step 1: Pump the brine from carbonate-type salt lakes (such as Zabuye Salt Lake in Tibet, Dangxung Co Salt Lake, Bangor Lake, etc.) into the frozen pre-drying pool 1, so that the brine will freeze and freeze naturally under low temperature conditions in winter 13 , forming pre-concentrated brine under ice;

[0070] Step 2: After deicing, the pre-concentrated brine is naturally evaporated in the open air, and under the action of solar radiation and wind, Glauber's salt and natron 14 are precipitated from the pre-concentrated brine in advance, thereby obtaining concentrated brine 15 after separating nitrate .

[0071] The above two steps can be carried out chronologically, or they can be naturally evaporated while deicing, and carried out at the same time.

[0072] In order to make full use of solar energ...

Embodiment 1

[0109] (1) Use the carbonate-type brine of Damxung Co Salt Lake in Tibet as the raw material brine, and first pour it into the first-stage frozen pre-drying pool 1 in early winter (October to November). The lighting area of the frozen pre-drying pool 1 is 1000m 2 , It is directly made of clay, and the bottom of the pool and the inner wall of the pool are provided with thermal insulation layers. On the inner surface of the pool, there is also an anti-seepage liner layer laid by black EPDM waterproof membrane.

[0110] The raw brine is 0.6m deep, and the brine is frozen under low temperature conditions in winter (December to March), and ice crystals or thin ice are formed on the surface of the brine. The ice crystals or thin ice are manually removed in time, and the ice is placed in a freshwater pool until the climate warms up. When it is melted into fresh water for other use.

[0111] During this period, the temperature range of the brine in the freezing pre-drying pool 1 i...

Embodiment 2

[0116] Other conditions are the same as in Example 1, except that a salt gradient heat preservation solar pond is also provided, and the salt gradient heat preservation solar pond is directly built from clay, and the lighting area is 100m2 , the depth of the pool is 2.0m, the bottom of the pool and the inner wall of the pool are made of plastic film and thermal insulation materials to form a sandwich structure of thermal insulation layer, and the inner surface of the pool is equipped with high-density polyethylene sprayed canvas as an anti-seepage liner; Heat exchangers are laid at a height of about 0.5m. The high-concentration lithium-rich brine obtained in Example 1 was pumped into the salt gradient heat preservation solar pond, the high-concentration lithium-rich brine was 1.0 m deep, and 0.3 m of fresh water was laid on it.

[0117] The inlet temperature of the geothermal water entering the heat exchange pipe is also 60-70°C, and the outlet temperature of the geothermal wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com