Catalyst for removing alkadiene in C4 and preparation method thereof

A catalyst and diene technology, which can be used in the purification/separation of hydrocarbons, chemical instruments and methods, catalysts for physical/chemical processes, etc. The effect of strong poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

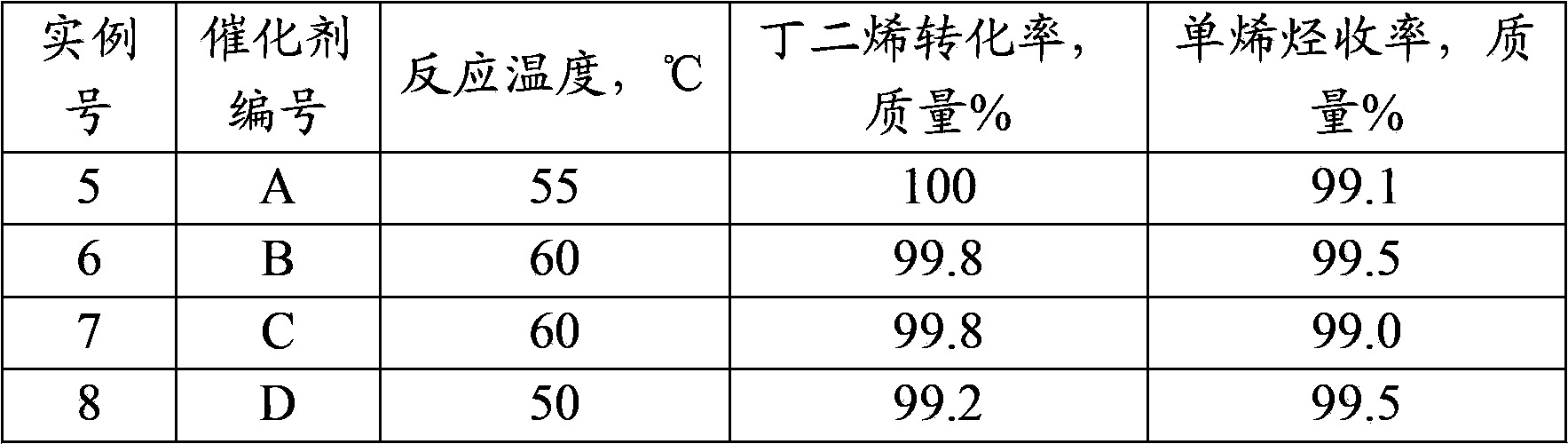

Examples

preparation example Construction

[0017] The preparation method of the catalyst provided by the present invention includes kneading calcium salt and alumina hydrate, molding, drying and roasting to obtain a composite carrier, impregnating the composite carrier with an aqueous solution of tungsten salt or tungstic acid, drying and roasting, and then water-soluble palladium-containing The solution of the compound is impregnated, dried and calcined.

[0018] In the above method, the method of kneading the calcium salt and the hydrated alumina is: adding dilute nitric acid solution to the powder of the calcium salt and the hydrated alumina, the concentration of the nitric acid aqueous solution is 1 to 3% by mass, kneading after stirring, and then extruding , the shaped shape can be strip, column or clover, preferably strip or clover. The shaped solid is dried and calcined to obtain a composite carrier. The drying temperature is preferably 80-130°C, the drying time is preferably 1-16 hours, the calcination tempera...

example 1

[0025] (1) Preparation of composite carrier

[0026] Get 900g pseudo-boehmite powder, 28g concentration is the HNO of 65 mass % 3 Add 900g deionized water, then add 84.5g Ca(NO 3 ) 2 4H 2 O to make a mixed solution, add this mixed solution to pseudo-boehmite powder and knead, extrude, dry at 120°C for 6 hours, and roast at 850°C for 6 hours to obtain a composite carrier, which contains 2.0% by mass of CaO, 98% by mass Aluminum oxide with a specific surface area of 124m 2 / g, the pore volume is 0.51ml / g.

[0027] (2) Preparation of catalyst

[0028] Take 36.67g of ammonium metatungstate, add deionized water to adjust the volume to 480ml to prepare an impregnation solution, immerse the composite carrier in the solution for 2 hours, dry at 120°C for 12 hours, and bake at 500°C for 6 hours to obtain a tungsten-containing carrier.

[0029] Take 5.67g PdCl 2 Dissolve the powder with hydrochloric acid, add deionized water to adjust the volume to 480ml, and obtain PdCl 2 sol...

example 2

[0031] Catalyst is prepared by the method for example 1, difference is (1) step used Ca (NO 3 ) 2 4H 2 O is 169g, contains 4.0% by mass of CaO, 96% by mass of alumina in the composite carrier obtained, and its specific surface area is 102m 2 / g, the pore volume is 0.38ml / g. After introducing tungsten and palladium in this composite carrier, obtain catalyst B, its Pd content calculated based on the composite carrier is 0.2 mass %, WO 3 The content is 3.0% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com