Preparation method of lithium ion battery negative electrode material

A lithium-ion battery and silicon negative electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low battery first efficiency, high oxygen content, poor cycle performance, etc., achieve rapid deintercalation and transfer, and high specific surface area , the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The silicon negative electrode material preparation method of lithium ion battery negative electrode material of the present invention comprises the following steps:

[0027] Put silicon monoxide into the reactor, feed inert gas and raise the temperature to 800°C-1100°C at a rate of 1-10°C / min, control the reaction temperature at 800°C-1100°C, keep the temperature constant for 3h-10h, and make the reactor fully react within;

[0028] After the reaction is completed, cool to room temperature, transfer to a container, then treat with acid or alkali, wash and dry to obtain silicon particles;

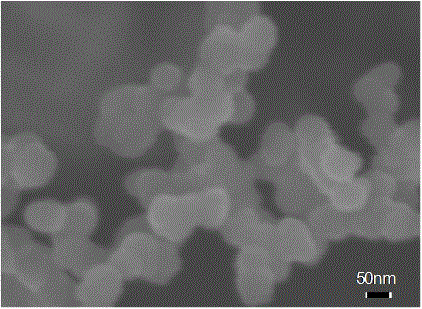

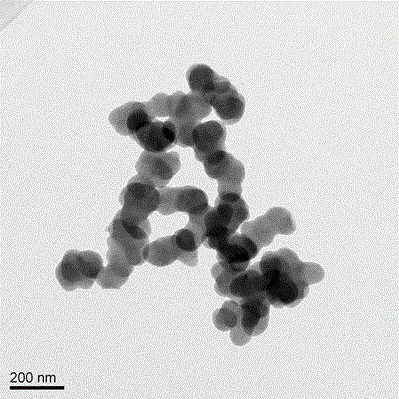

[0029] Put the above-mentioned silicon particles into the reactor again, feed carbon source gas with a flow rate of 1g / min to 20g / min, and carry out carbon coating at a temperature of 300°C to 1000°C, and the carbon coating reaction time is 0.1h to 1h After the carbon coating is completed, cool to room temperature to obtain a carbon-coated silicon negative electrode material. The si...

Embodiment 1

[0039] Prepare lithium ion battery negative electrode material by above-mentioned preparation method of the present invention:

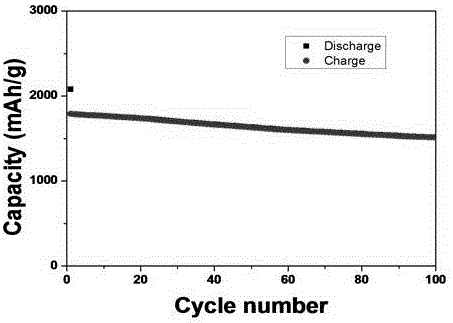

[0040] Put 1kg of SiO powder into the reaction furnace, pass inert gas, and increase the temperature at 5°C / min to 900°C, keep the temperature at a constant temperature for 6 hours to fully react in the reaction furnace and cool to room temperature, transfer the sample to the container, Treat with hydrofluoric acid for 5 hours, then wash and dry to obtain silicon particles of nano-silicon material;

[0041] Put the above-mentioned silicon particles into the reactor again, pass in an inert gas, then heat up to 500°C at a rate of 5°C / min, and then pass in an acetylene gas with a flow rate of 10g / min to treat the silicon negative electrode material. Carbon coating, constant temperature for 0.5h, and then cooling to room temperature to obtain a carbon-coated nano-silicon material, that is, the silicon negative electrode material of the present invention. ...

Embodiment 2

[0045] Prepare lithium ion battery negative electrode material by above-mentioned preparation method of the present invention:

[0046] Put 1kg of SiO powder into the reaction furnace, pass inert gas, and increase the temperature at 1°C / min to 800°C, keep the temperature at a constant temperature for 10 hours to fully react in the reaction furnace, then cool to room temperature, transfer the sample to the container, Treat with sodium hydroxide for 3h, then wash and dry to obtain silicon particles of nano-silicon material;

[0047] Put the above-mentioned silicon particles into the reactor again, pass inert gas, then heat up to 300°C at a rate of 2°C / min, and then pass in acetylene gas with a flow rate of 10g / min to treat the silicon negative electrode material. Carbon coating, constant temperature for 1 hour, and cooling to room temperature to obtain a carbon-coated nano-silicon material, that is, the silicon negative electrode material of the present invention.

[0048] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com