Low-viscosity grinding cutting fluid

A cutting fluid, low viscosity technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of high treatment cost, oily wastewater, pollution of the environment, etc., and achieve the effects of easy cleaning, low viscosity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

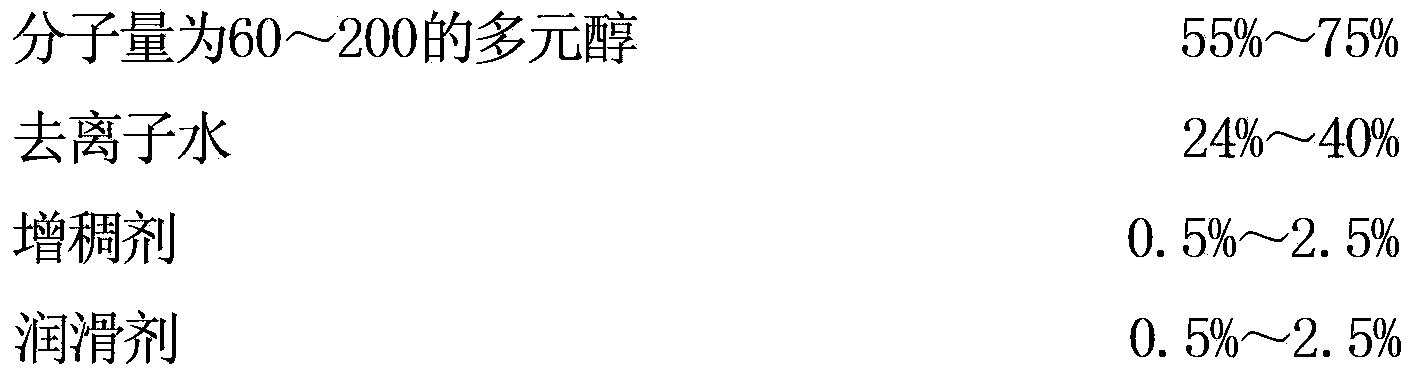

[0017] Taking the preparation of 1kg of low-viscosity grinding and cutting fluid as an example, the raw materials and quality ratios used are as follows:

[0018]

[0019] The preparation method of the above-mentioned low-viscosity grinding and cutting fluid is as follows: according to the mass ratio of the above-mentioned raw materials, 343g of deionized water, 285g of glycerin and 350g of 1,2-propanediol are sequentially added to a 2L stirring tank, and the low-speed stirrer is started to heat the material. When the temperature of the material in the mixing tank is 45°C, slowly add 7g of hydroxyethyl cellulose, continue to stir until the cellulose particles are soaked, start the high-speed disperser, stir at 1000 rpm for 60 minutes, add 15g of triethanolamine boron Ester, continue to stir for 120 minutes, and prepare 1 kg of low-viscosity abrasive cutting fluid.

Embodiment 2

[0021] Taking the preparation of 1kg of low-viscosity grinding and cutting fluid as an example, the raw materials and quality ratios used are as follows:

[0022]

[0023] The aforementioned Cabot fumed silica CAB-O-SIL M-5 was provided by Shanghai Kaiyin Chemical Co., Ltd.

[0024] Its preparation method is identical with embodiment 1.

Embodiment 3

[0026] Taking the preparation of 1kg of low-viscosity grinding and cutting fluid as an example, the raw materials and quality ratios used are as follows:

[0027]

[0028] The above-mentioned bentonite YH-D was provided by Zhejiang Anji Yuhong Clay Chemical Co., Ltd.

[0029] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com