Thermoplastic polyurethane elastomer foam material and preparation method thereof

A technology of thermoplastic polyurethane and foaming materials, which is applied in the field of polymer materials, can solve the problems of decreased mechanical properties, reduced use performance, and low foaming ratio, so as to improve the strength and resistance to compression set, and solve the problems of short service life, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

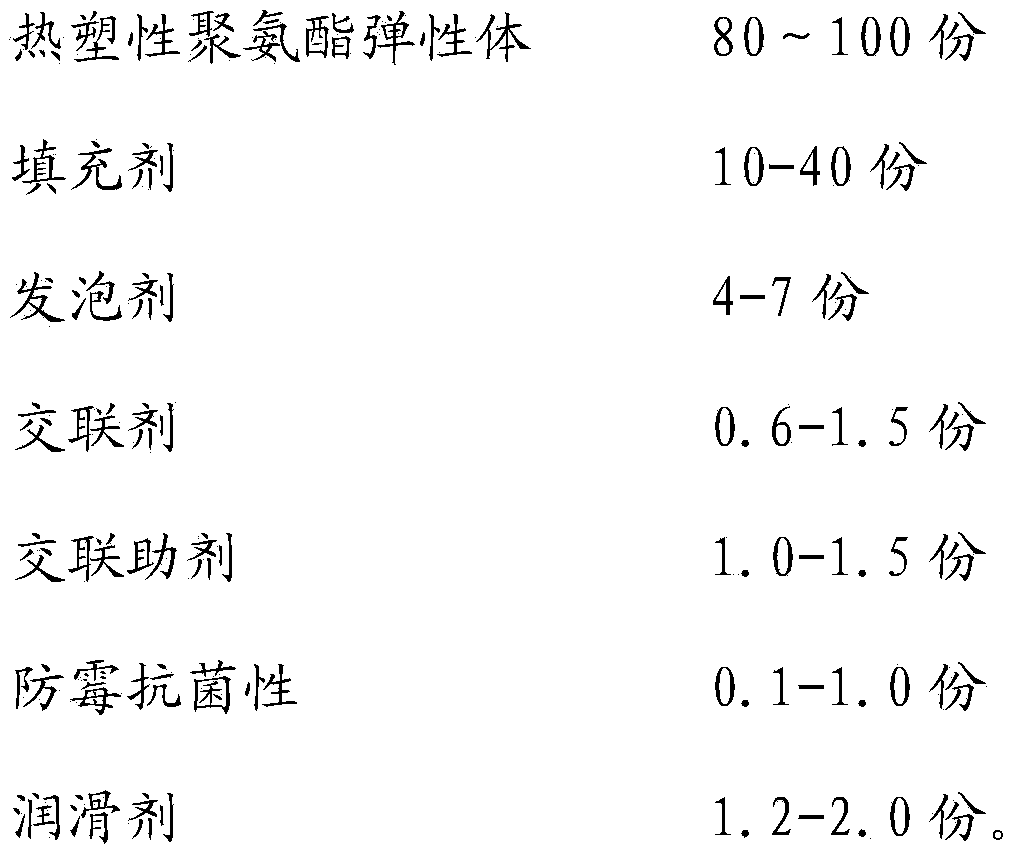

[0021] A thermoplastic polyurethane elastomer foaming material in Example 1 is mainly prepared from the following raw materials in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 10 parts of filler, 5 parts of foaming agent, 1.0 part of crosslinking agent, 1.0 part of cross-linking auxiliary agent, 0.1 part of anti-mildew and antibacterial property, 1.2 part of lubricant.

[0022] Among them, the thermoplastic polyurethane elastomer is a soft polyester thermoplastic polyurethane elastomer with a Shore hardness of 60-75HA, a Vicat softening point of 100-130°C, and a melt flow rate of 1.0-8.0g / 10min; the filler is Talc powder, stearic acid as a lubricant, azodicarbonamide as a foaming agent, bis-tert-butylperoxycumene as a crosslinking agent, triallyl isocyanurate as a crosslinking aid, The antifungal and antibacterial agent is 8-hydroxyquinolinone.

[0023] In the present embodiment, filler also can replace talcum powder with calcium carbonate or the mixing...

Embodiment 2

[0039]A thermoplastic polyurethane elastomer foaming material in the second embodiment is mainly prepared from the following raw materials in parts by weight: 80 parts of thermoplastic polyurethane elastomer, 40 parts of filler, 7 parts of foaming agent, 0.8 part of crosslinking agent, 1.2 parts of cross-linking auxiliary agent, 0.5 parts of mildew and antibacterial properties, and 1.5 parts of lubricant.

[0040] Among them, the thermoplastic polyurethane elastomer is a soft polyester thermoplastic polyurethane elastomer with a Shore hardness of 60-75HA, a Vicat softening point of 100-130°C, and a melt flow rate of 1.0-8.0g / 10min; the filler is Calcium carbonate, lubricant is stearic acid, foaming agent is azodicarbonamide, crosslinking agent is dicumyl peroxide, crosslinking agent is trimethylolpropane trimethacrylate, mildew and antibacterial The agent is nano silver antibacterial agent.

[0041] The preparation method of a kind of thermoplastic polyurethane elastomer foam...

Embodiment 3

[0050] A thermoplastic polyurethane elastomer foaming material in the third embodiment is mainly prepared from the following raw materials in parts by weight: 90 parts of thermoplastic polyurethane elastomer, 25 parts of filler, 5 parts of foaming agent, 0.9 part of crosslinking agent, 1.2 parts of cross-linking auxiliary agent, 1.0 parts of anti-mold and antibacterial properties, and 1.5 parts of lubricant.

[0051] Among them, the thermoplastic polyurethane elastomer is a soft polyester thermoplastic polyurethane elastomer with a Shore hardness of 60-75HA, a Vicat softening point of 100-130°C, and a melt flow rate of 1.0-8.0g / 10min; the filler is Calcium carbonate, unsaturated fatty acid zinc salt as lubricant, azodicarbonamide as foaming agent, dicumyl peroxide as crosslinking agent, trimethylolpropane trimethacrylate as crosslinking aid, anti The mildew antibacterial agent is an organosilicon quaternary ammonium salt antibacterial agent.

[0052] A kind of preparation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com