Nonmetal-doped titanium dioxide, preparation method thereof and degradable plastic film

A technology of titanium dioxide and plastic film, which is applied in the field of degradable plastic film, can solve the problems of plastic pollution, achieve the effects of low cost, cheap and non-toxic raw materials, and increase the utilization rate of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Adding N-TiO 2 Photooxidation-Biodegradation of Composite Thin Films

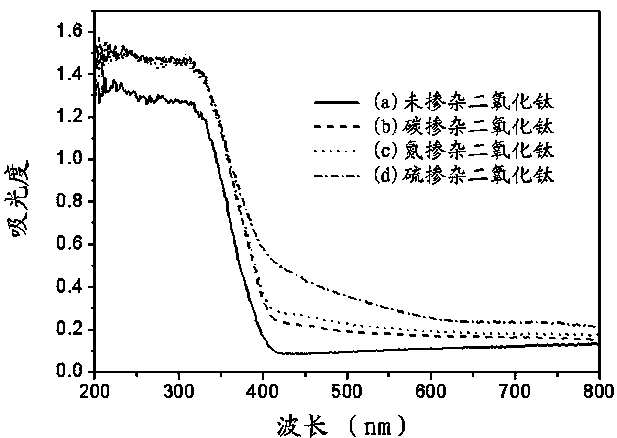

[0031] S1. Nitrogen-doped titanium dioxide (N-TiO 2 ) powder preparation: add 6.0g nano-titanium dioxide, 0.6g hexamethylenetetramine (or urea, ammonium carbonate and other nitrogen sources), 4 large stainless steel balls, and 20 small stainless steel balls in a stainless steel grinding jar. Seal it well. On a planetary ball mill (or other ball mill), the speed is 300~400 rpm, ball mill for 1~4 hours, take out the ground powder, grind it finely, put it into a crucible, and in a muffle furnace, 400~ Calcined at 500°C for 1 to 2 hours to obtain nitrogen-doped titanium dioxide (N-TiO 2 )powder. Determination of the properties of nitrogen-doped titanium dioxide, the results show that N-TiO 2 The absorption band edge of the undoped titanium dioxide is obviously red-shifted, and in the ultraviolet and visible parts of N-TiO 2 The absorption spectrum of the titanium dioxide is stronger than ...

Embodiment 2

[0033] Example 2: Adding S-TiO 2 or C-TiO 2 Photooxidation-Biodegradation of Composite Thin Films

[0034] S1. Sulfur-doped titanium dioxide (S-TiO 2 ) or carbon-doped titanium dioxide (C-TiO 2 ) powder preparation: the same as step S1 of the above-mentioned embodiment 1, but the doping source is adjusted, the sulfur source is thiourea, elemental sulfur, etc., and the carbon source is carbon tetrachloride, xylene and other hydrocarbon compounds. Prepared S-TiO 2 and C-TiO 2 catalyst powder. The analysis shows that, like the photocatalysts prepared in Example 1, their absorption band edges are all more red-shifted than those of undoped titanium dioxide, and in the ultraviolet and visible parts S-TiO 2 and C-TiO 2 The absorption spectrum of the titanium dioxide is stronger than that of undoped titanium dioxide, and it has the activity of degrading the film under ultraviolet and visible light. The results are shown in figure 1 .

[0035] S2. is the same as step S2 of the...

Embodiment 3

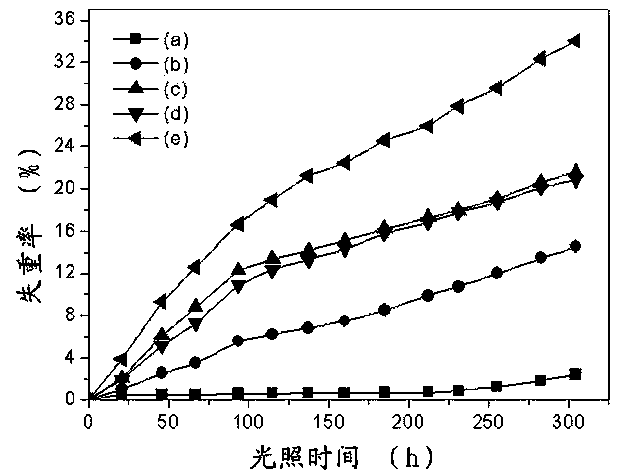

[0038] Embodiment 3: adding different S-TiO 2 Photooxidation-Biodegradation of Mass Ratio Composite Thin Films

[0039] S1. Sulfur-doped titanium dioxide (S-TiO 2 ) powder preparation: the same as step S1 of the above-mentioned embodiment 2, the doping source is thiourea, and S-TiO 2 catalyst powder.

[0040] S2. Same as step S2 of the above-mentioned embodiment 1, but adjust S-TiO 2 The proportions of powder and LDPE resin were 1%, 2% and 3%, respectively, to obtain LDPE / 1%S-TiO 2 、LDPE / 2%S-TiO 2 、LDPE / 3%S-TiO 2 Composite film. Studies have shown that after 300 hours of UV light, LDPE / 1%S-TiO 2 、LDPE / 2%S-TiO 2 、LDPE / 3%S-TiO 2 The weight of the composite film is reduced by 34%, 40%, and 45% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com