Preparation method of porous graphene-polymer composite material

A porous composite material and porous material technology, which is applied in the field of graphene-polymer composite material preparation, can solve problems such as few studies, and achieve the effects of large specific surface area, low cost and controllable pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

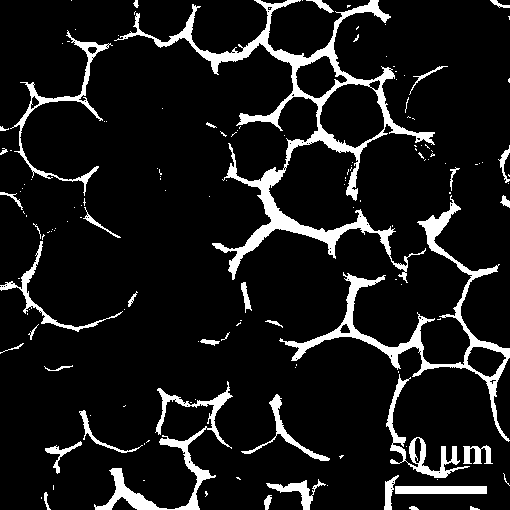

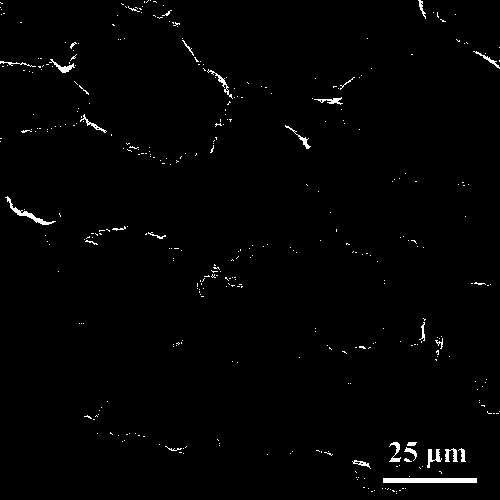

Image

Examples

Embodiment 1

[0026] 1. In 100 parts of water, add 0.05 parts of GO, the average size of the GO sheet used is 5 μm. In the GO aqueous dispersion, add 0.025 parts of CTAB while stirring while dripping, and continue to sonicate for 40 min to make the dispersion uniform. Centrifuge and wash to remove excess surfactant. Re-dispersed in water, the mass fraction of GO at this time is 0.05%.

[0027] 2. In the above modified GO aqueous dispersion, add methyl methacrylate monomer, whose mass is 15% of the mass of the water phase, and add crosslinking agent ethylene glycol dimethacrylate, whose mass is mono 20% of the body mass, and finally add the initiator azobisisobutyronitrile, whose mass is 1% of the monomer mass.

[0028] 3. Homogenize the above mixed liquid at 5000 rpm for 15 min to form W / O type HIPE. The obtained HIPE is transferred to a hydrothermal reactor, filled with nitrogen and sealed. Put in 65 o C. In a blast oven, react for 24 h.

[0029] 4. Put the product obtained from the above re...

Embodiment 2

[0031] 1. The experimental device and operation are the same as in Example 1. Replace CTAB in Example 1 with di-C 10 A mixture of BA and dodecyltrimethylammonium bromide, where di-C 10 The weight ratio of BA to dodecyltrimethylammonium bromide is 2:1, the average size of the GO sheet is 50 nm, the mass fraction of the GO aqueous dispersion is changed to 0.2%, and the surfactant is twice the mass of GO .

[0032] 2. The experimental device and operation are the same as in Example 1. The monomer is changed to styrene, whose mass is 10% of the mass of the water phase; the cross-linking agent is changed to divinylbenzene, whose mass is 100% of the mass of styrene; initiator Changed to azobisisoheptonitrile, the mass is 2% of styrene.

[0033] 3. The experimental device and operation are the same as in Example 1. The homogenization is changed to ultrasonic treatment, the ultrasonic power is 1000 W, and the time is 50 min; the oven temperature is changed to 51 o C. The reaction time is ...

Embodiment 3

[0036] 1. The experimental device and operation are the same as in Example 1. The mass fraction of the GO aqueous dispersion in Example 1 is changed to 0.005%, the average size of the GO sheet is 20 μm, and the CTAB is changed to dodecyltrimethylammonium bromide , Its quality is 10% of GO quality.

[0037] 2. The experimental device and operation are the same as in Example 1. The monomer is changed to acrylamide, whose mass is 40% of the water phase; the crosslinking agent is changed to bisacrylamide, whose mass is 10% of the monomer; the initiator is changed to Potassium persulfate, its mass is 2% of the monomer; adding the porogen cyclohexane, the mass is 5 times that of the water phase.

[0038] 3. The experimental device and operation are the same as in Example 1. The speed is adjusted to 500 rpm; the time is changed to 5 min; the O / W type HIPE is obtained; the oven temperature is changed to 75 o C, the reaction time is changed to 8 h.

[0039] 4. The product obtained by the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com