Parallel light curing equipment with staggered area array light sources and curing method thereof

A technology of dislocation arrangement and curing equipment, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., which can solve the problem of low calorific value, UVLED luminous intensity, uniformity, and important indicators that are difficult to achieve actual results. And other problems, to improve the uniformity of irradiation, improve the effect of curing, improve the effect of optical power density and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

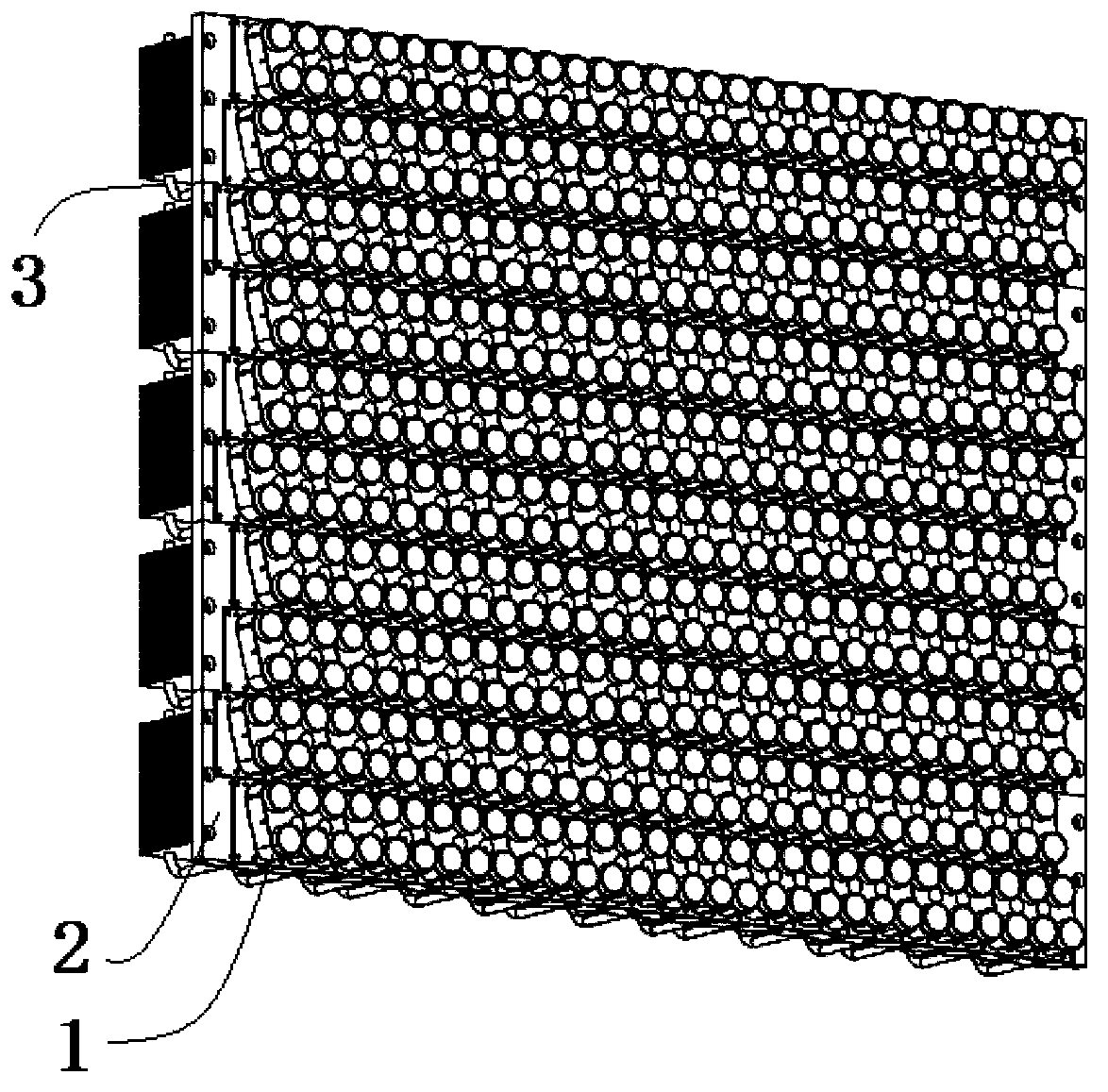

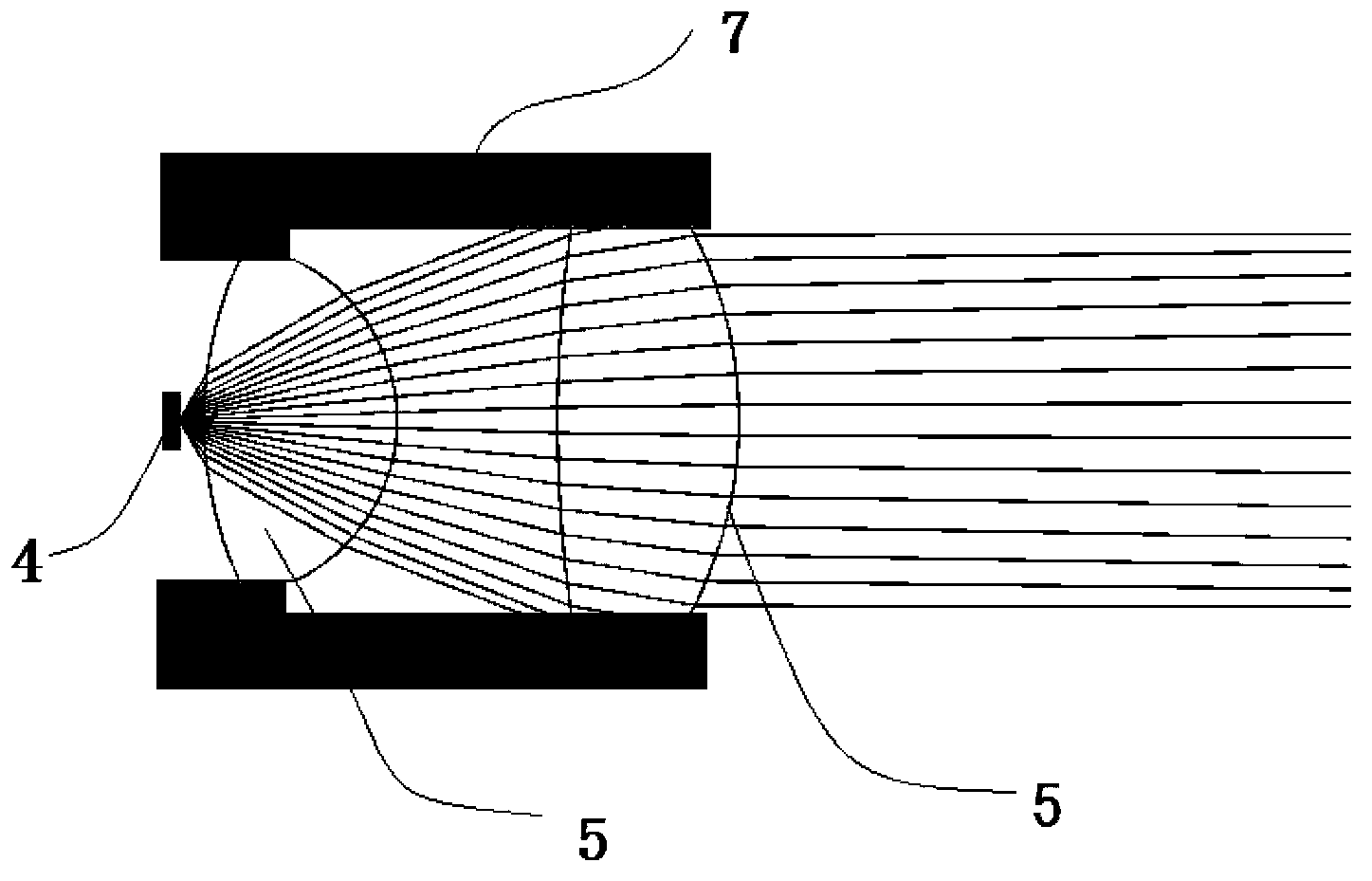

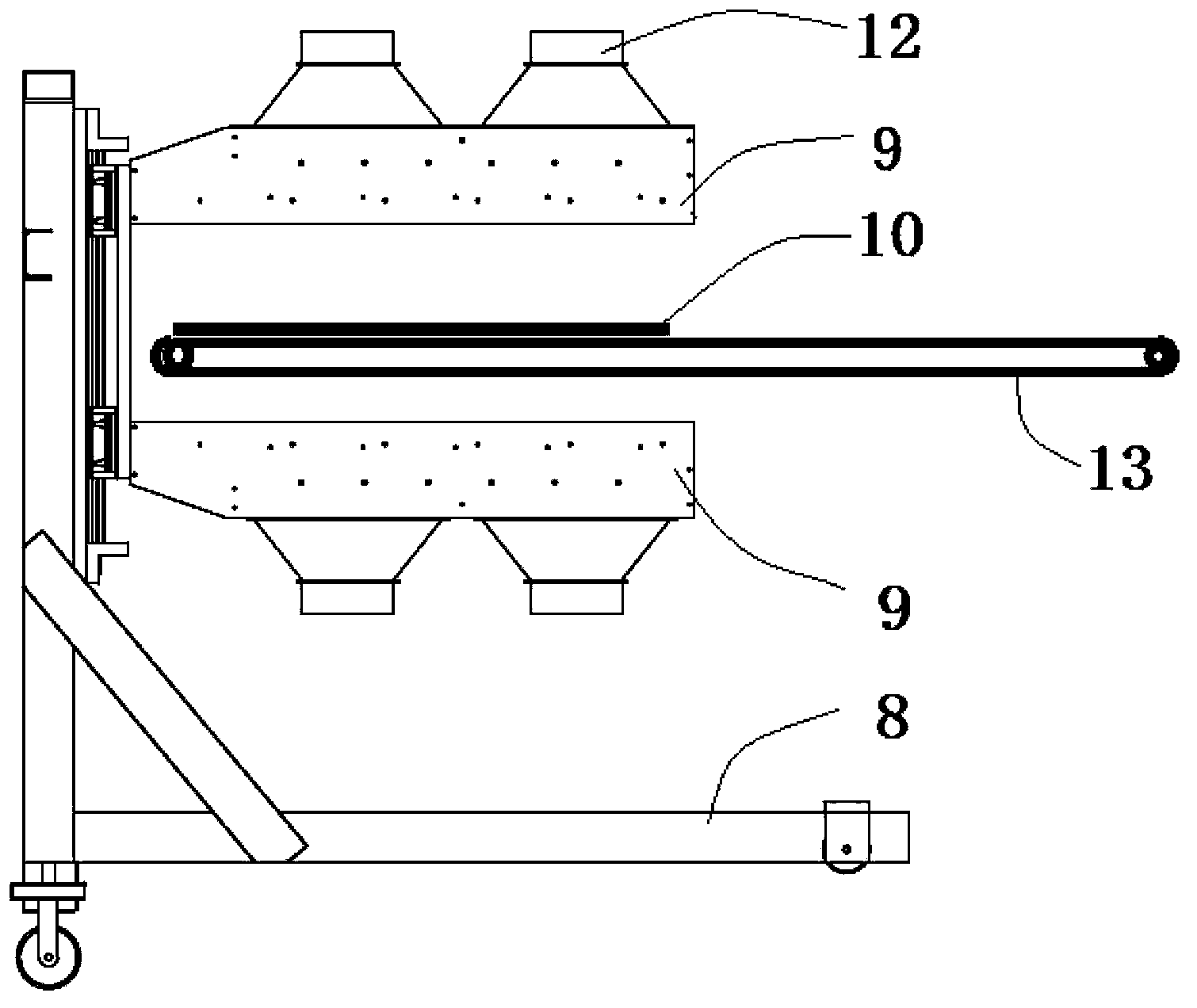

[0046] join Figure 1 to Figure 5 , the parallel photocuring equipment of the area array light source dislocation arrangement provided by the present invention, it comprises a conveying device 13, an area array light source curing device, a heat dissipation device connected with the area array light source curing device, a connection with the area array light source curing device The light source control device and the workbench for installing the above-mentioned devices; the workbench includes a trolley 8, which is movably arranged in the workbench, and the upper part of the trolley 8 is provided with a longitudinal guide rail and a guide rail drive mechanism, the area array light source curing device is arranged on the guide rail of the trolley 8; the conveying device 13 fixes a workpiece 10 to be cured by vacuuming, and transports the workpiece 10 to be cured to the area array light source curing device. directly above or directly below.

[0047] The area array light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com