Method for preparing electrolytes of all-vanadium flow battery

An all-vanadium redox flow battery and electrolyte technology, which is applied in the field of liquid flow battery preparation, can solve problems such as unfavorable evaporation and crystallization, unstable sulfurous acid, and difficult removal of impurities, so as to reduce energy consumption, reduce production time, and save equipment input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

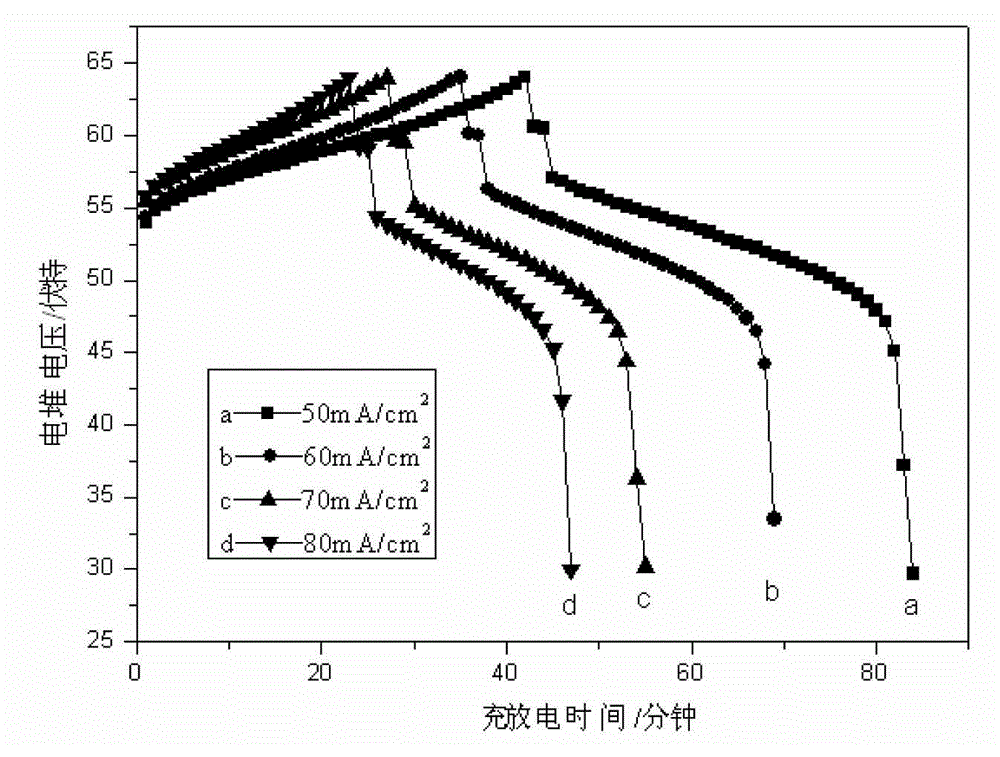

Embodiment 1

[0015] Take purity 99% H 2 2g, 99.8% pure V 2 o 5 18.2g, high temperature (80 ℃) sintering, the resulting solid (V 2 o 4 Powder, V 2 o 3 Powder) is dissolved in 9.8 g of concentrated sulfuric acid of 18.4 mol / liter to obtain an electrolyte solution that can be used in an all-vanadium redox flow battery. Put the prepared electrolyte into the electrolytic cell for charging and discharging experiments: the charging platform is 1.7V, the discharging platform is 1.4V, and in the assembled stack, the current density is 50mA / cm 2 , the obtained current efficiency is 93.8%, the voltage efficiency is 88.3%, and the energy efficiency is 82.%.

Embodiment 2

[0017] Take purity 99% H 2 4g, 99.8% pure V 2 o 5 18.2g, high temperature (210 ℃) sintering, the resulting solid (V 2 o 4 Powder, V 2 o 3 Powder) was dissolved with 9.8 g of concentrated sulfuric acid at 10.0 mol / liter to obtain an electrolyte that can be used for all-vanadium redox flow batteries. Put the prepared electrolyte into the electrolytic cell for charging and discharging experiments: the charging platform is 1.7V, the discharging platform is 1.4V, and in the assembled stack, the current density is 60mA / cm 2 , the obtained current efficiency is 93.9%, the voltage efficiency is 86.1%, and the energy efficiency is 80.8%.

Embodiment 3

[0019] Take purity 99% H 2 3g, 99.8% pure V 2 o 5 18.2g, high temperature (500 ℃) sintering, the resulting solid (V 2 o 4 Powder, V 2 o 3Powder) was dissolved in 9.8 g of 6 mol / L concentrated sulfuric acid to obtain a vanadium battery electrolyte of 1:1 ratio between trivalent vanadium and tetravalent vanadium. Put the prepared electrolyte into the electrolytic cell for charging and discharging experiments: the charging platform is 1.7V, the discharging platform is 1.4V, and in the assembled stack, the current density is 70mA / cm 2 , the obtained current efficiency is 94.9%, the voltage efficiency is 83.3%, and the energy efficiency is 79.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage efficiency | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com