Cyclone Separator for Circulating Fluidized Bed Boiler with Wear-Resistant Target Area and Guide

A technology of circulating fluidized bed and cyclone separator, which is applied to fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., can solve the problem of fine particles affecting boiler operation economy and the difficulty of corrugated surface construction , aggravate the wear and tear of the heating surface of the tail, and achieve the effects of harsh working environment, improved anti-wear performance and large thermal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

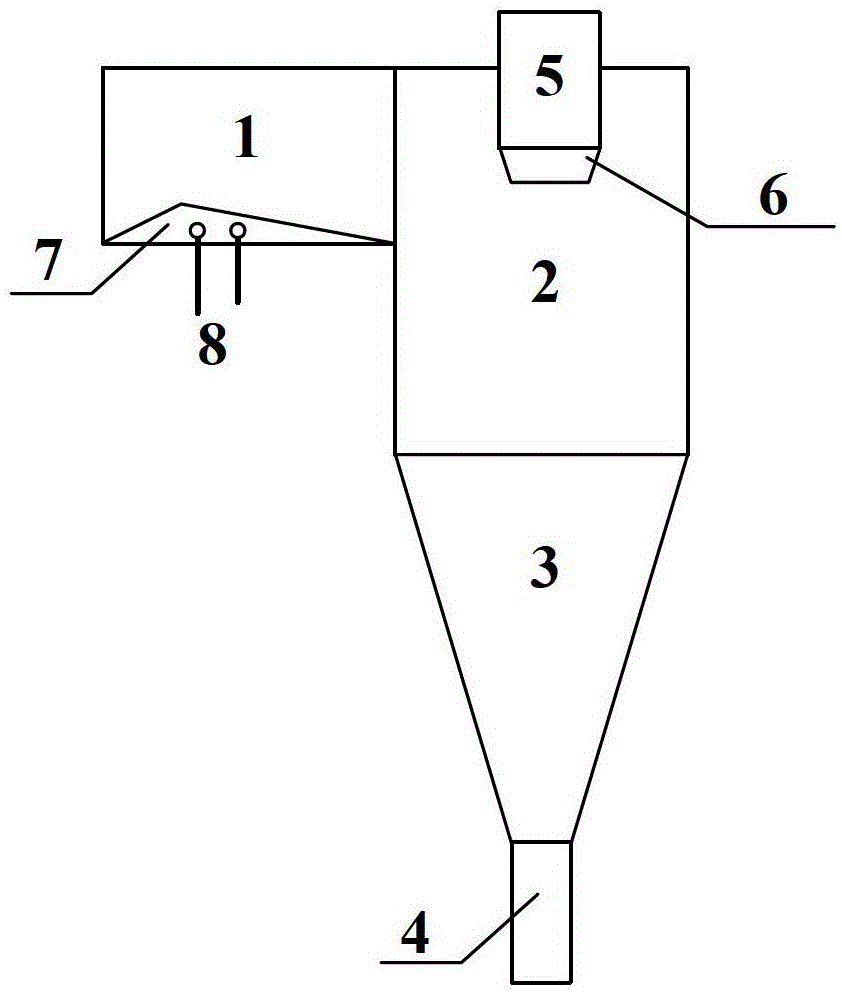

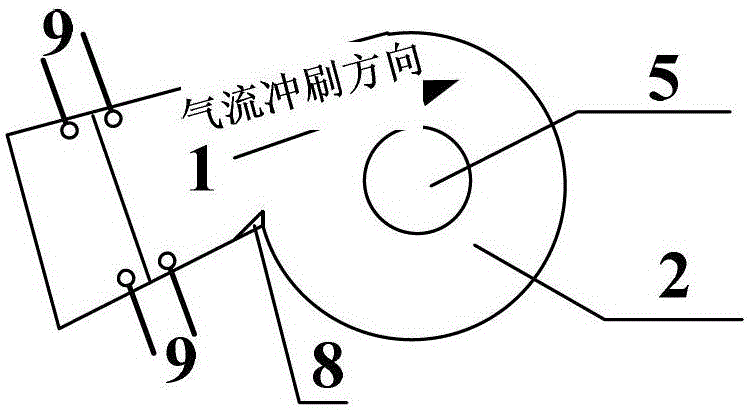

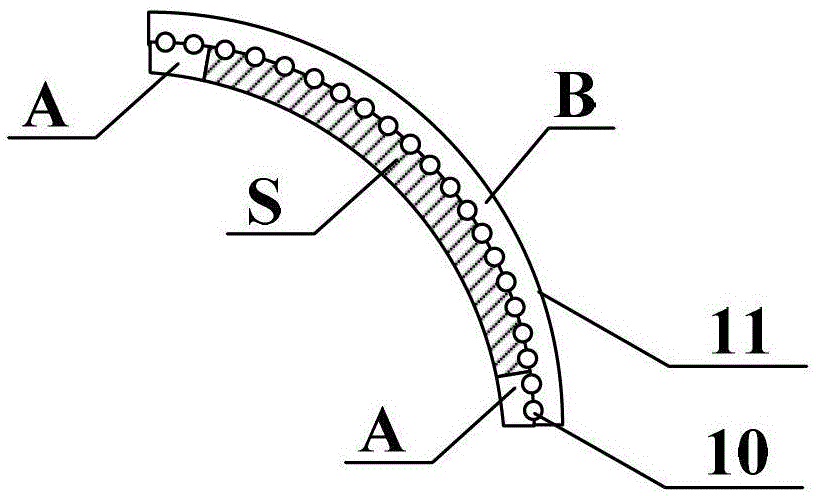

[0039] This embodiment is a circulating fluidized bed boiler cyclone separator with a wear-resistant target area and a guide device. The cyclone separator is a steam-cooled type. The total depth of the separator is 60% of the height of the inlet flue 1 of the separator, and the minimum diameter of the constriction 6 of the central cylinder is 60% of the diameter of the central cylinder 5; the inlet flue 1 of the separator is a tapered inlet flue, and its outlet area It is 50% of the entrance area; the flue gas guiding boss 7 is installed in the separator inlet flue 1, the angle between the flue gas guiding boss 7 near the boiler side and the horizontal plane is 30°, and it is close to the outlet side of the separator cylinder 2 The included angle with the horizontal plane is 10°; in addition, the end of the separator inlet flue 1 is provided with a flue gas guide port 8 for further optimizing the flow field in the separator to improve the separation efficiency. A soot purge po...

Embodiment 2

[0044] This embodiment is a circulating fluidized bed boiler cyclone separator with a wear-resistant target area and a guide device. The cyclone separator is adiabatic. The total depth of the separator is 80% of the height of the separator inlet flue 1, and the minimum diameter of the central cylinder necking 6 is 90% of the diameter of the central cylinder 5; the separator inlet flue 1 is a tapered inlet flue, and its outlet area is 70% of the entrance area; the flue gas guiding boss 7 is installed in the separator inlet flue 1, the angle between the flue gas guiding boss 7 near the boiler side and the horizontal plane is 40°, and the outlet side near the separator cylinder 2 and the The included angle of the horizontal plane is 15°; in addition, the end of the separator inlet flue 1 is provided with a flue gas guide port 8 for further optimizing the flow field in the separator to improve the separation efficiency. A soot purge port 9 is arranged around the flue gas guide bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com