Gamma ray irradiation-resistant polypropylene material and preparation method thereof

A polypropylene material and gamma ray technology, applied in the field of polypropylene material and its preparation, can solve the problems of accelerated PP oxidation degradation, product color yellowing, etc., and achieve good mechanical properties and low yellowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a gamma ray radiation-resistant polypropylene material, comprising the following steps:

[0026] 1) Dry the raw materials;

[0027] 2) Put the dried polypropylene in boiling xylene, add the dried stabilizer and antioxidant, stir for 2-3 hours, cool down to room temperature, suction filter and dry to obtain a masterbatch, and place the masterbatch in Melt and extrude in an extruder, draw, cool, dry, and pelletize.

[0028] The dosage ratio of polypropylene and xylene is 1g: (100-150)ml.

Embodiment 1

[0031] A kind of gamma ray radiation-resistant polypropylene material, its formula composition is as follows:

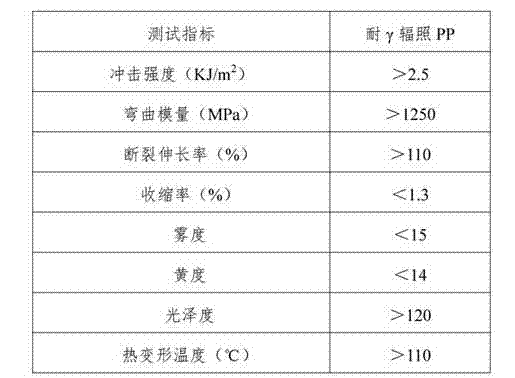

[0032] Table 1

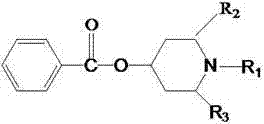

[0033] raw material mass percentage PP 99 % Antioxidant 1076 0.5% (1,2,2,6,6-pentamethyl)piperidinol benzoate margin

Embodiment 2

[0035] A kind of gamma ray radiation-resistant polypropylene material, its formula composition is as follows:

[0036] Table 2

[0037] raw material mass percentage PP 99% Antioxidant 1010 0.3% (1,2,2,6,6-pentamethyl)piperidinol benzoate margin

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com