Preparation method of high-performance PVDF composite ultrafiltration membrane with surface loaded with TiO2 thin membrane

A surface-loaded, high-performance technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult industrial production, complicated process, and high cost of membrane production, and achieve the effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

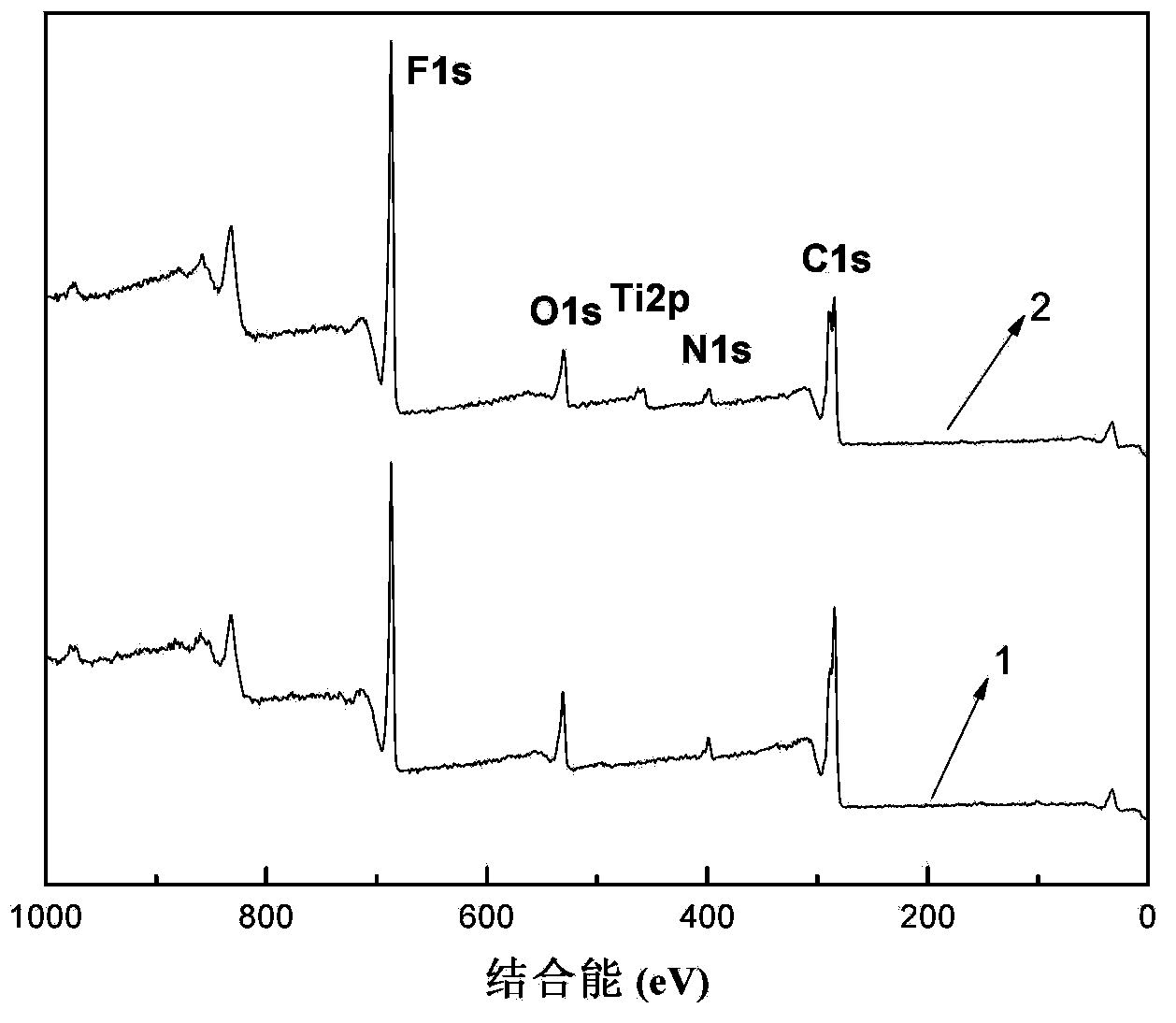

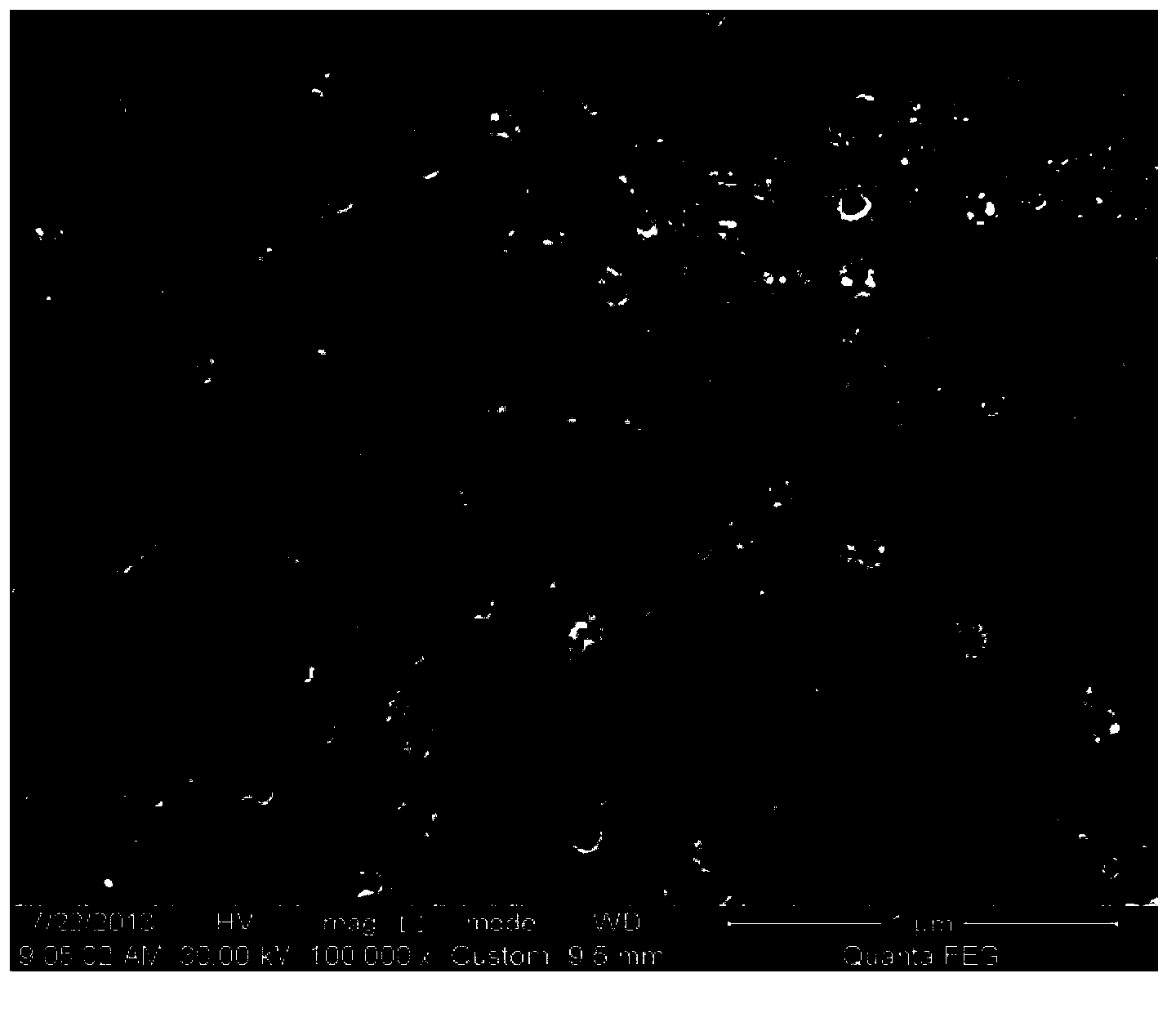

[0019] Specific embodiment one: a kind of surface load TiO of this embodiment 2 The preparation method of the high-performance PVDF composite ultrafiltration membrane of thin film, carries out according to the following steps:

[0020] Step 1. Preparation of ultrafiltration base membrane by immersion-precipitation method: Prepare PVDF polymer casting solution, pour the prepared casting solution on a glass plate, scrape and coat the casting solution on the glass plate with a film scraper, and then Immerse the glass plate in distilled water at room temperature, and form a layer of film after the casting solution is solidified, then immerse the obtained film in distilled water, let it stand for more than 9 hours, and take it out for use; wherein, the casting solution is composed of PVDF, PVP and Solvent composition, the mass percentage of the PVDF is 12%-20%, the mass percentage of the PVP is 0.20%-0.30%, and the mass percentage of the solvent is 87.80%-79.70% , the solvent is N...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass percentage of PVDF in the PVDF polymer casting solution described in step 1 is 14%, 16% or 18%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass percentage of PVP described in step 1 is 0.26%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Retention rate | aaaaa | aaaaa |

| Retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com