Alicyclobacillus immunomagnetic microspheres and application thereof

A Bacillus and magnetic microsphere technology, applied in the field of immunomagnetic microspheres, can solve the problems of high cost, increased production cost, decreased filtering effect, etc., and achieves the effects of low cost, good effect and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

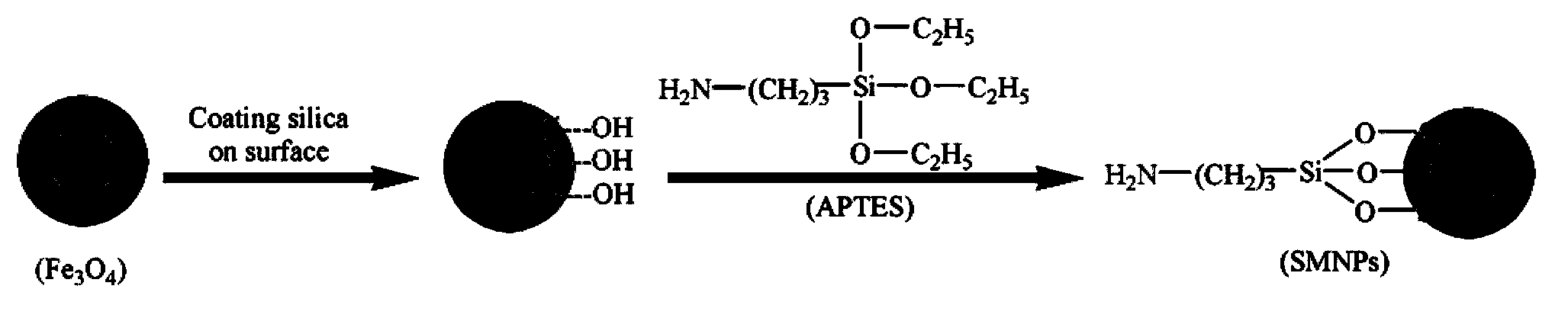

[0044] (1) Silanization reaction of magnetic microspheres

[0045] Dissolve 9.5g of sodium silicate in 200mL of deionized water and adjust the pH value to 12-13 with hydrochloric acid, add 5g of Fe to the sodium silicate solution 3 o 4 Ultrasonic treatment with magnetic core for 30 minutes, adjust the pH of the reaction system to 6-7 with hydrochloric acid in a water bath at 80-90°C, obtain microspheres by magnetic separation and wash with water to obtain silanized magnetic microspheres with a neutral pH;

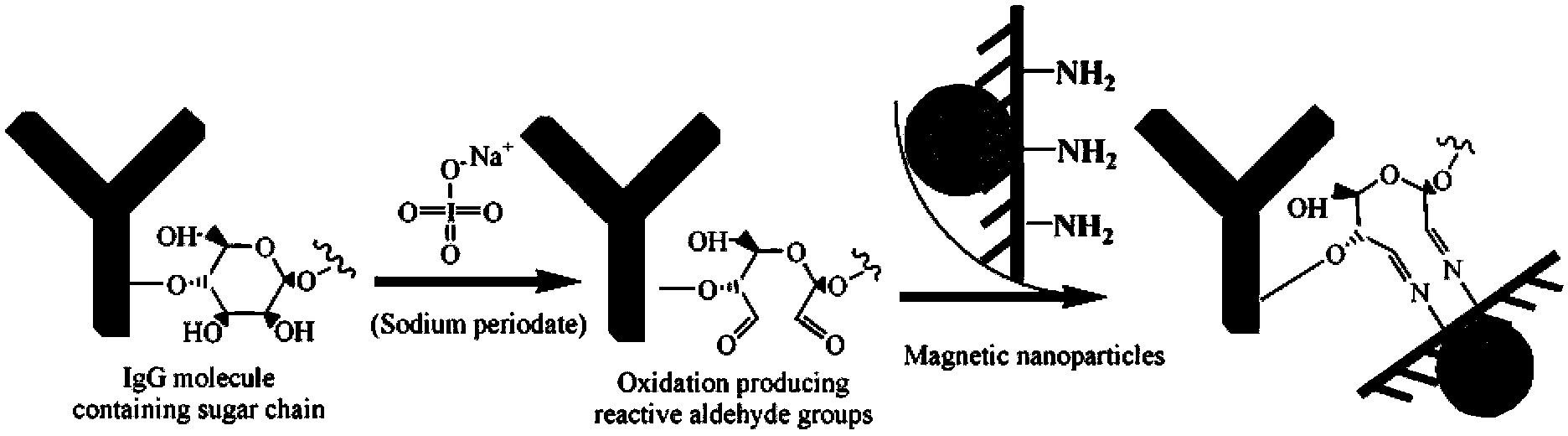

[0046] (2) Amination modification of magnetic microspheres

[0047] Add 2 grams of silanized magnetic microsphere suspension, 1mL deionized water and 10mL APTES to 150mL methanol, add 150mL glycerin after ultrasonic treatment for 30min, fully react at 85-90℃ for 3h, obtain microspheres by magnetic separation, and use methanol and deionized water Washing three times respectively, freeze-drying to obtain aminated magnetic microspheres, and the particle diameter of the amina...

Embodiment 2

[0053] This example differs from example 1 in that the Fe used in this example 3 o 4 The magnetic core is prepared by the following method:

[0054] 3.4g of FeCl 3 ·6H 2 O with 1.2g FeCl 2 4H 2 O was added to 800mL deionized water, and 4g PEG-4000 was added, fully stirred and dissolved under the protection of nitrogen, and ammonia solution was added dropwise to make the pH of the reaction system greater than 10; after that, the reaction system was fully matured in a water bath at 75-85°C for 20-40min , the microspheres were obtained by magnetic separation and washed with water to obtain Fe 3 o 4 Magnetic nucleus; the Fe was detected 3 o 4 The magnetic core particle size is 15-25nm, and the magnetic saturation magnetization is 72.18emu / g.

Embodiment 3

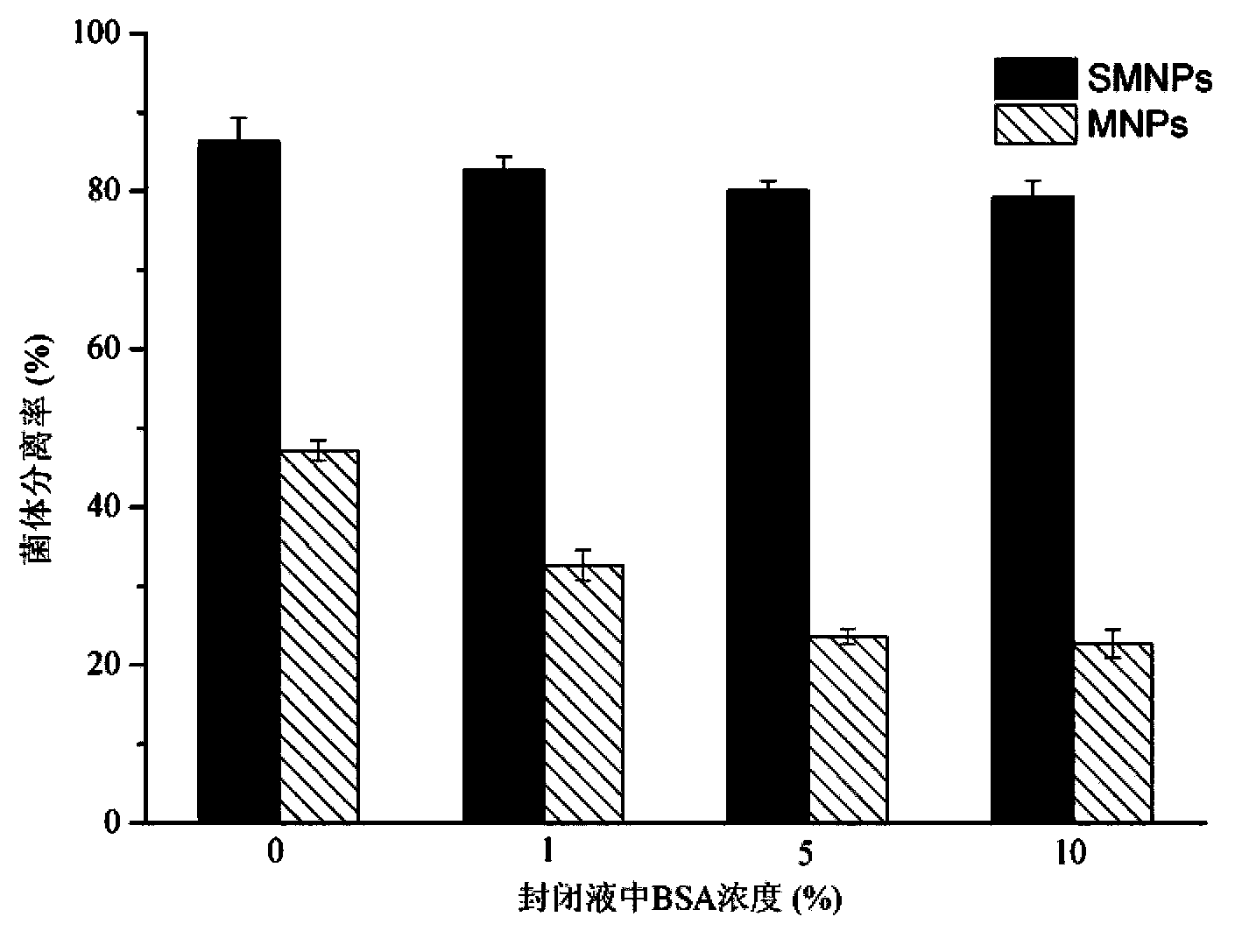

[0056] The difference between this example and Example 1 is that the immunomagnetic microspheres of this example are blocked by a blocking solution: use a mixed system containing 5g BSA and 0.05ml Tween-20 per 100ml of PBS as the blocking solution, and add the adsorbed antibody The immunomagnetic microspheres were reacted at 37° C. for 60 min, and then magnetically separated and fully washed to obtain the immunomagnetic microspheres after blocking treatment.

[0057] One, utilize the immunomagnetic microsphere prepared in embodiment 3 to separate Alicyclobacillus:

[0058] The specific operation steps are: prepare 10 mL of the concentration gradient samples shown in Table 1, add 20 mg of immunomagnetic microspheres to each sample to separate and remove the target bacteria: 120-180 rpm, reaction adsorption time 60 min; magnetic separation and adsorption of bacteria The immunomagnetic microbeads were washed with sterile water and suspended in 200 μL of PBS buffer. The change of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com