Environment-friendly and easy-to-attract floor and manufacturing method thereof

A production method and floor technology are applied in the field of decoration products, which can solve the problems of non-moisture-proof, inelastic products, complicated construction, etc., and achieve the effect of increasing toughness and strong self-suction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

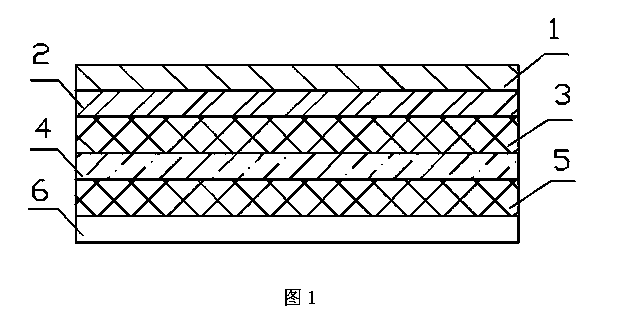

[0019] Such as figure 1 As shown, an environmentally friendly and easy-absorbing floor is composed of a wear-resistant layer 1, a printed leather layer 2, a first filling layer 3, a glass fiber layer 4, a second filling layer 5 and a self-absorbing layer 6 from bottom to bottom.

[0020] Its preparation method comprises the following steps:

[0021] The first step is to discharge the printed skin layer 2, the first filling layer 3, the glass fiber layer 4, the second filling layer 5 and the self-priming layer 6 from top to bottom in order at a temperature of 150 degrees and a pressure of 40-50 tons Pressing and shaping into semi-finished products;

[0022] In the second step, UV technology is used to cover the upper surface of the printed cortex 2 with 8-10 grams of UV paint per square meter;

[0023] The third step is tempering at a high temperature of 90 degrees,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com