A preparation method of precursor for magnetic flocculation and iron removal of hydrometallurgical acid leaching liquid

An acid leachate and hydrometallurgy technology, applied in the field of comprehensive utilization of resources, can solve the problems of unsatisfactory quality of precipitated slag, difficult filtration of fine particles, slow sedimentation and sedimentation speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

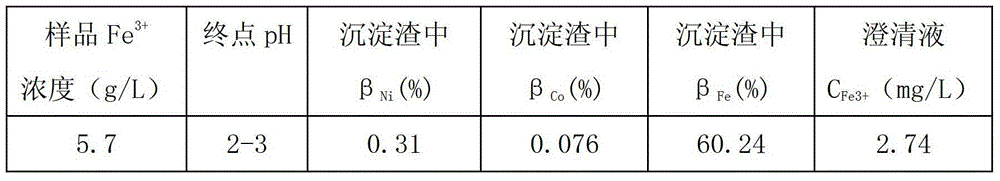

[0031] Grind fayalite until the particle size is less than 74um, take 1 part and add 10 parts to phosphate starch solution with a mass concentration of 0.1%, soak for 1 hour, filter and separate; grind pyrolusite until the particle size is less than 74um, take 1 part and add 10 Soak in a CGM solution with a mass concentration of 0.1% for 0.5 hours, filter, separate and dry; mix pyrolusite and fayalite at a mass ratio of 1:2, and grind in a ceramic ball mill for 1 hour to obtain a precursor. It is used in the iron removal process of nickel sulfate in the high-pressure leaching solution of nickel smelting. Table 1 is the main component of the precipitated slag obtained in this embodiment and Fe 3+ concentration.

[0032] Table 1

[0033]

Embodiment 2

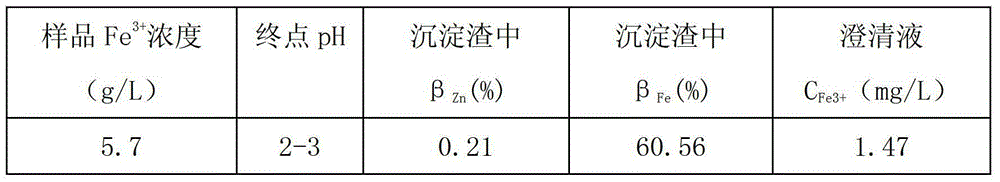

[0035] Grind the magnetite until the particle size is less than 74um, take 1 part and add 7 parts to the CMC solution with a mass concentration of 0.1%, soak for 1 hour, filter and separate; grind the ilmenite until the particle size is less than 74um, take 1 part and add 5 parts Soak in CGM solution with a mass concentration of 0.1% for 0.5 hours, filter, separate and dry; mix ilmenite and magnetite at a mass ratio of 1:3, grind in a ceramic stirring mill for 1 hour, and dry to obtain a precursor . It is used in the iron removal process of zinc sulfate in the high-pressure leaching solution of zinc smelting. Table 2 is the main component of the precipitated slag obtained in this embodiment and Fe 3+ concentration.

[0036] Table 2

[0037]

Embodiment 3

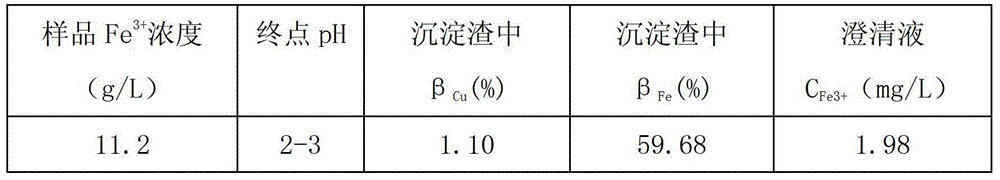

[0039] Grind titanomagnetite to a particle size of less than 74um, take 1 part and add 5 parts of xanthate starch solution with a mass concentration of 0.1%, soak for 1 hour, filter and separate; grind hematite to a particle size of less than 74um, take 1 Add 5 parts of CGM solution with a mass concentration of 0.1% and soak for 0.5 hours, filter, separate and dry; mix titanomagnetite and hematite at a mass ratio of 1:2, grind in a planetary mill for 0.5 hours, and dry , to obtain the precursor. It is used in the iron removal process of copper sulfate in the high-pressure leaching solution of copper smelting. Table 3 is the main component of the precipitated slag obtained in this embodiment and Fe 3+ concentration.

[0040] table 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com