motor control unit

A technology of motor control and magnetic flux controller, applied in motor generator control, AC motor control, control of electromechanical transmission devices, etc. High-speed threading, suppression of sudden change in excitation current, and improvement of characteristic deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0066] [Structure of Motor Control Unit]

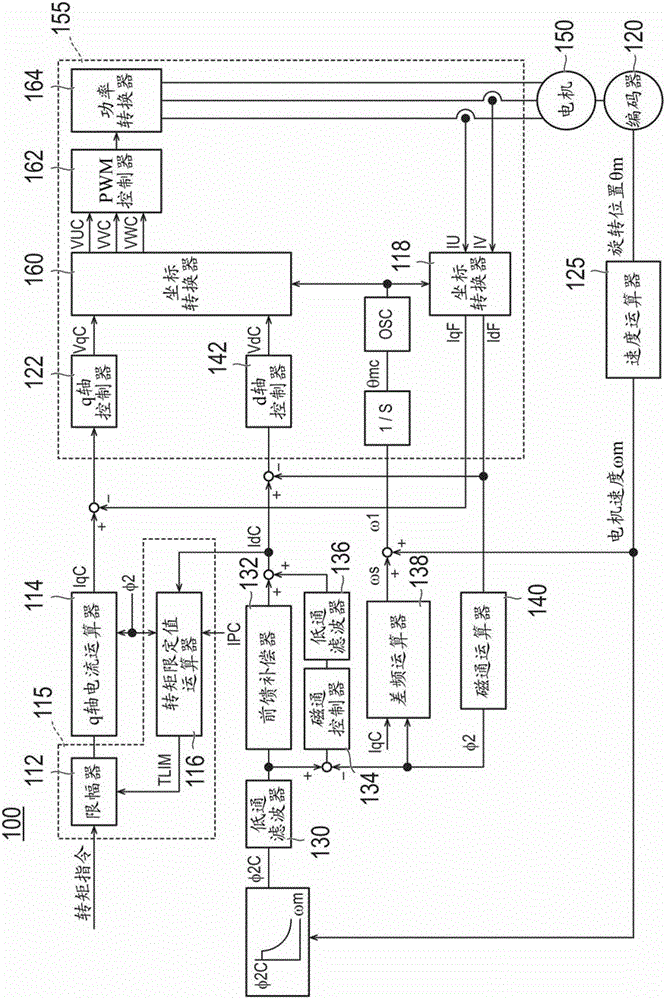

[0067] figure 1 It is a block diagram of the motor control device 100 of Embodiment 1.

[0068] As a system for providing the q-axis voltage command VqC, the motor control device 100 has a limiter 112, a q-axis current calculator 114, a torque limit value calculator 116, a coordinate converter 118, an encoder 120, a q-axis controller 122 and Speed calculator 125. In addition, a torque command limiting unit 115 is constituted by a limiter 112 and a torque limit value calculator 116 .

[0069] The limiter 112 limits the received torque command using the torque limit value TLIM calculated by the torque limit value calculator 116 .

[0070] The q-axis current calculator 114 is used to output the q-axis current command IqC, which is obtained from the torque command output by the limiter 112 and the magnetic flux φ2 output by the magnetic flux calculator 140 .

[0071] Torque limit calculator 116 calculates torque limit TLIM received...

Embodiment approach 2

[0118] [Structure of Motor Control Unit]

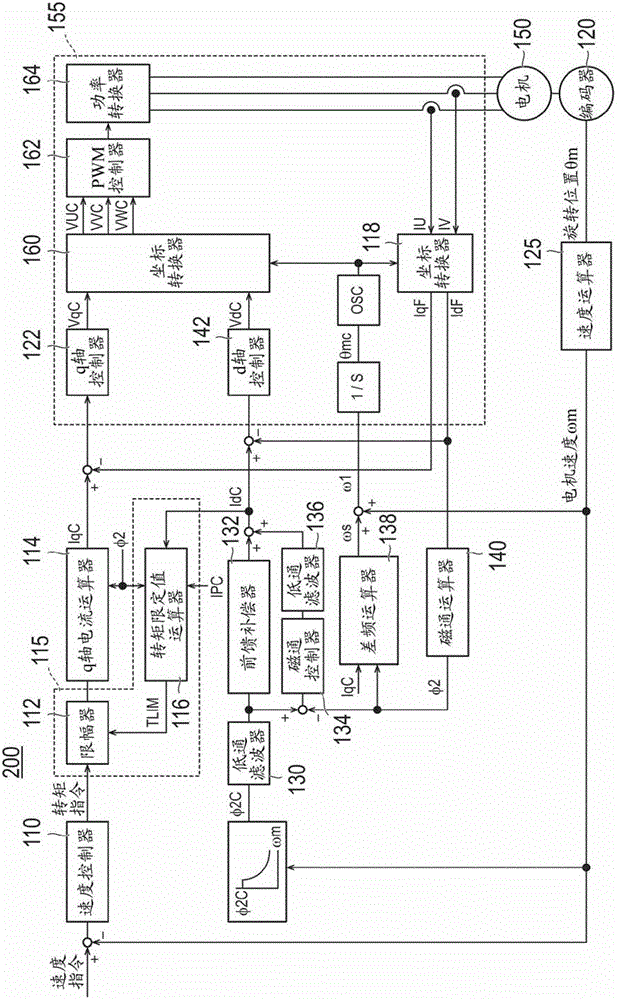

[0119] figure 2 It is a block diagram of the motor control device 200 of Embodiment 2. right figure 2 in and figure 1 The same constituent elements, labeled with figure 1 The same reference numerals.

[0120] The motor control device 200 differs from the motor control device 100 of the first embodiment in that only the speed controller 110 is provided as a system for providing the q-axis voltage command VqC.

[0121] The speed controller 110 subtracts the speed feedback from the speed calculator 125 from the received speed command, and outputs a torque command from the subtracted speed command.

[0122] The limiter 112 limits the torque command output from the speed controller 110 using the torque limit value TLIM calculated by the torque limit value calculator 116 .

[0123] The functions of the q-axis current calculator 114 , the torque limit value calculator 116 , the coordinate converter 118 , the encoder 120 , the q-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com