Organometallic compounds and thin film using same

An organic metal and metal thin film technology, which is applied in the fields of organic chemistry, compounds of Group 5/15 elements of the periodic table, metal material coating processes, etc. Semiconductor mass production process and other issues, to achieve the effects of excellent chemical and thermal stability, improved film deposition rate, and excellent step coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] On the other hand, in relation to this, the present invention provides a method for preparing a metal-containing thin film, the method comprising: step a) providing a vapor containing the various types of organometallic compounds; and step b) making the vapor according to a deposition method It reacts with the substrate to form a metal-containing complex layer on at least one surface of the substrate.

[0082] The use of the above preparation method to form a substrate can not only improve the substrate adsorption efficiency, but also improve safety, and can increase the film deposition speed to shorten the process time. Moreover, not only can the pollution in the process be reduced, but it can also be used in a wider temperature range, and the reliability and efficiency of the manufacturing process can be significantly improved. In addition, a thin film with good uniformity and improved step coating characteristics can be obtained by the above preparation method.

[0083] ...

Embodiment 1

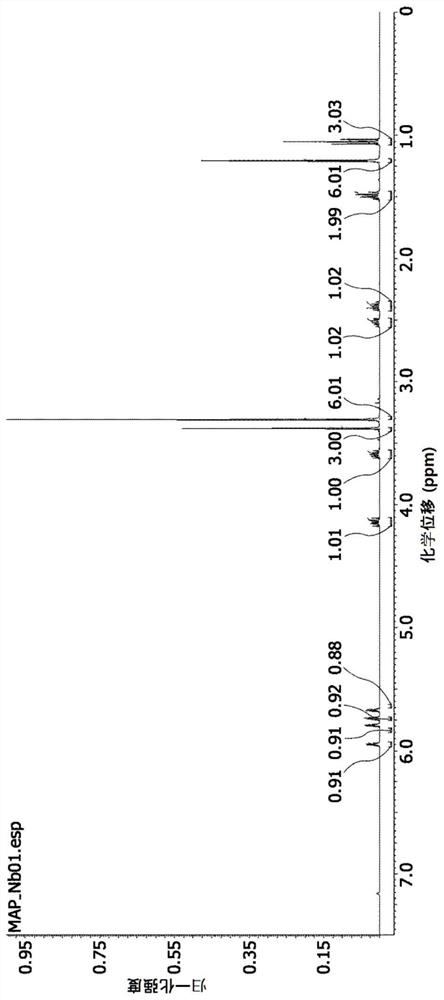

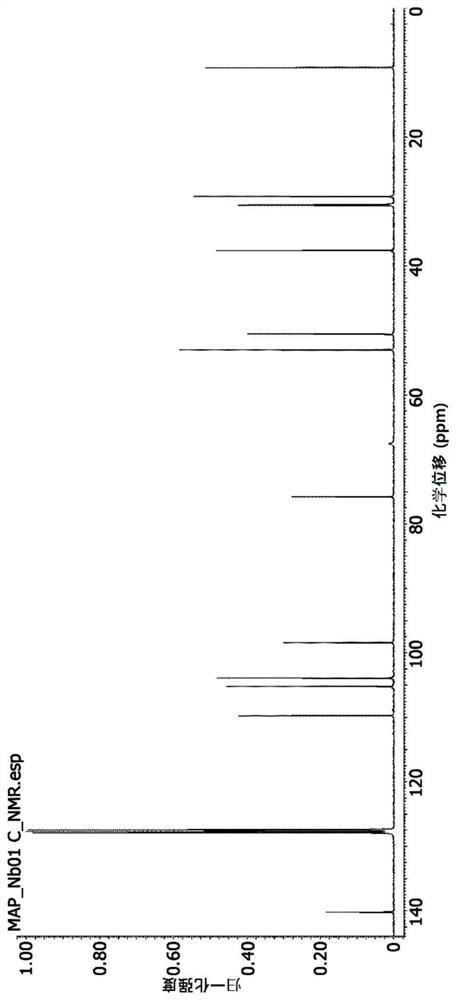

[0101] Example 1 (Nb)

[0102] (1) Preparation and synthesis of novel compounds

[0103] [Reaction formula 1]

[0104]

[0105] After dissolving 17g of dimethylamine in toluene, the solution was added dropwise to 141ml of 2.5M butyllithium solution at -20°C, and stirred at room temperature for 2 hours to obtain dimethylamine lithium salt. Rate: 90%). After 32.7 g of tert-amylamine was dissolved in toluene, 22.5 mL of chlorotrimethylsilane was added dropwise, and the mixture was stirred for 15 minutes. After that, after passing the reaction product through diatomaceous earth, the reaction product was dropped into a reaction vessel containing toluene in which 21.8 g of niobium chloride was dissolved, and the mixture was stirred for 1 hour. 25 mL of pyridine was added dropwise thereto, and the mixture was stirred for 12 hours. After that, the reaction product was passed through diatomaceous earth, and then the solvent was removed under reduced pressure to obtain tert-amylamine niobi...

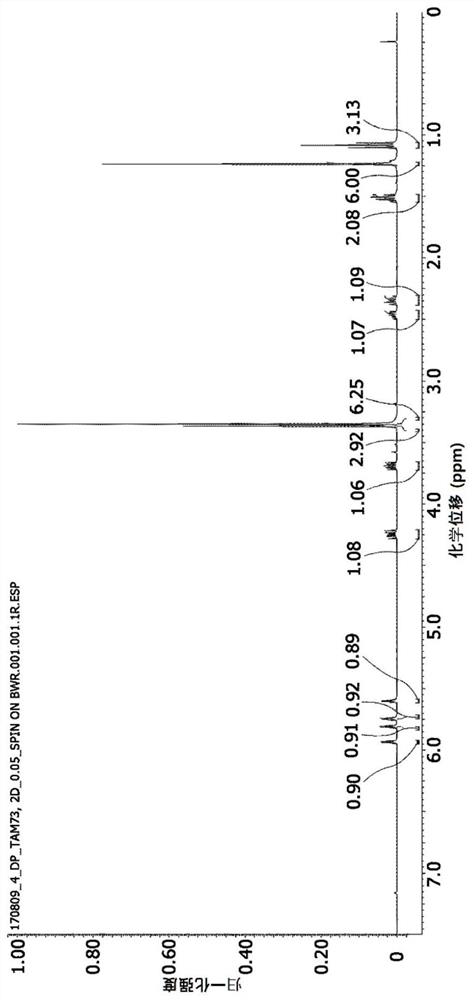

Embodiment 1-1

[0108] The silicon wafer is immersed in sulfuric acid (H 2 SO 4 ) And hydrogen peroxide water (H 2 O 3 ) In a piranha solution mixed at a volume ratio of 4:1 for 10 minutes and taken out, then the silicon wafer is immersed in a dilute HF aqueous solution for 2 minutes to form a pure silicon surface, and then the above Map-Nb01 is used as the precursor To deposit NbN film by plasma atomic layer deposition (PEALD) method. At this time, the temperature of the substrate is heated to 300°C to 450°C, and the precursor is diluted with octane in a stainless steel container so that the viscosity is adjusted to 4 cps to 10 cps, and evaporated by an evaporator. At this time, the supply time to the precursor in the reactor is 5 seconds to 20 seconds, the flow rate of ammonia gas as a reducing agent is 100 sccm, and the supply time is adjusted to 5 seconds to 20 seconds.

[0109] After supplying the precursor and ammonia gas, argon gas was added as a purge gas for 30 seconds. It can be seen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com