Magnesium chloride/silicon dioxide/tetrahydrofuran loaded late transition metal catalyst and preparation method and application thereof

A technology of late transition metal and silica, applied in the application field of the catalyst in the gas phase polymerization or copolymerization of ethylene, can solve the problems of high catalyst loading cost, limited industrial application, uncontrollable, etc., and achieve good hydrogen regulation sensitivity performance and copolymerization performance, high ethylene polymerization catalytic activity, good particle morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

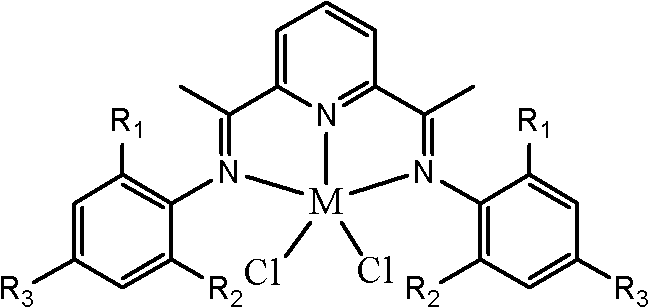

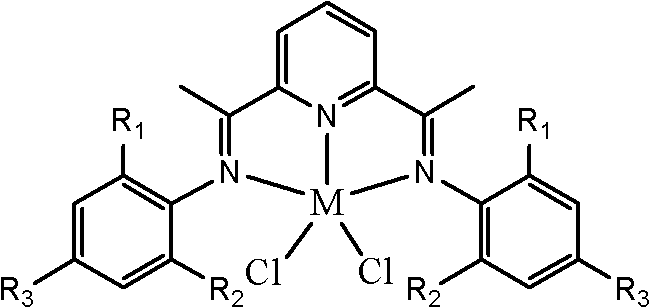

[0030] 1. Preparation of supported catalyst 2,6-bis[1-(2,6-dimethylphenylimine)ethyl]pyridine ferric dichloride Under nitrogen protection, in a 250mL reactor, add anhydrous magnesium chloride 4.868 g, add 130 mL of refined THF, and keep stirring at a constant temperature of 70°C for 1 hour. Add 7.510 g of TS-610 silica gel replaced by nitrogen into the reactor, keep the temperature at 30° C., and stir for 1 hour. Add 0.1937 g of iron homogeneous catalyst 2,6-bis[1-(2,6-dimethylbenzimine)ethyl]pyridine ferric dichloride, and stir at 30°C for 15 minutes. The stirred mother liquor is spray-dried with a spray drying device, the inlet temperature is set to 182°C, the outlet temperature is 98°C, the pumping speed percentage is 100%, the pump speed percentage is 30%, and the nozzle cleaning frequency is 7 times / min , 8.6219 g of the supported catalyst was obtained, the iron content measured by atomic absorption spectroscopy was 0.25%, the tetrahydrofuran content measured by gas chro...

Embodiment 2

[0034] 1. Preparation of supported catalyst 2,6-bis[1-(2,6-dimethylbenzimine) ethyl]pyridine ferric dichloride

[0035]Under the protection of nitrogen, in a 250mL reactor, add 4.85g of anhydrous magnesium chloride, add 130mL of refined THF, and keep stirring at a constant temperature of 70°C for 1 hour. Add 7.55 g of TS-610 silica gel replaced by nitrogen into the reactor, keep the temperature at 30° C., and stir for 1 hour. Add 0.3812 g of iron homogeneous catalyst 2,6-bis[1-(2,6-dimethylbenzimine)ethyl]pyridine ferric dichloride, and stir at 30°C for 15 minutes. The stirred mother liquor was spray-dried with a spray dryer, the inlet temperature was set to 182°C, the outlet temperature was 98°C, the pump speed percentage was 30%, the nozzle cleaning frequency was 7 times / min, and 8.7325g of supported catalyst was obtained. The iron content measured by absorption spectrum was 0.47%, the tetrahydrofuran content determined by gas chromatography was 29.5%, and the particle size...

Embodiment 3

[0039] 1. Preparation of supported catalyst 2,6-bis[1-(2,6-diisopropylphenylimine)ethyl]pyridine ferric dichloride

[0040] Under the protection of nitrogen, in a 250mL reactor, add 4.8703g of anhydrous magnesium chloride, add 130mL of refined THF, and keep heating and stirring at a constant temperature of 70°C for 1 hour. Add 7.5350 g of TS-610 silica gel replaced by nitrogen into the reactor, keep the temperature at 30° C., and stir for 1 hour. Add 0.2145 g of iron homogeneous catalyst 2,6-bis[1-(2,6-diisopropylphenylimine)ethyl]pyridine ferric dichloride, and stir at 30° C. for 15 minutes. The stirred mother liquor is spray-dried with a spray dryer, the inlet temperature is set to 182°C, the outlet temperature is 98°C, the pumping speed percentage is 100%, the pump speed percentage is 30%, and the nozzle cleaning frequency is 7 times / min. 8.9930 g of the supported catalyst was obtained, the iron content measured by atomic absorption spectroscopy was 0.22%, the tetrahydrofu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com