Hollow polymer particle and manufacturing method thereof

A manufacturing method and polymer technology, which can be used in the preparation of microspheres, microcapsule preparations, temperature recording methods, etc., can solve the problems of low hollow particles and other problems, reduce the generation of concave particles, improve the thermal insulation effect, and make a leap in recording sensitivity Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In a 1000 ml four-necked flask to which 201.2 g of deionized water was added, 0.6 g of a condensate of adipic acid and diethanolamine was dissolved as a dispersing aid, and 8.5 g of colloidal silica was added as a dispersing agent. The pH of this aqueous solution was adjusted to 3.0 with 4.5 g of 3% dilute sulfuric acid aqueous solution, and it was set as the aqueous phase.

[0077] 11.2 g of methyl methacrylate, 1.3 g of acrylonitrile as a polymerizable monomer, 12.5 g of trimethylolpropane trimethacrylate as a crosslinking agent, and 150.0 g of n-heptane as an organic solvent were mixed to form an oil phase.

[0078] Mix the water phase and the oil phase, and stir for 6 minutes with a T.K automatic homomixer M type (manufactured by Tokuki Kagaku Kogyo Co., Ltd.) at a speed of 12,000 rpm. After adjusting the particle size to 1 to 10 μm, add 2,2'-azo 0.1 g of bisisobutyronitrile was used as a polymerization initiator, nitrogen substitution was performed, and polymerizat...

Embodiment 2

[0086] As a diluent of the fine particle dispersion which contains n-heptane inside and the polymerization is completed, 385.0 g of warm water (85° C.) which has an azeotropic point of n-heptane and water, which is 79° C. or higher, is added. In the same manner, polymer microparticles with a high hollow ratio in a wet state were produced.

[0087] Maintaining the temperature of the dispersion from the start of the polymerization reaction to the vaporization and removal of the organic solvent has never been cooled, and performed the same operation as in Example 1 to vaporize and remove n-heptane contained in the microparticles, thereby obtaining Made of hollow particles in a wet state.

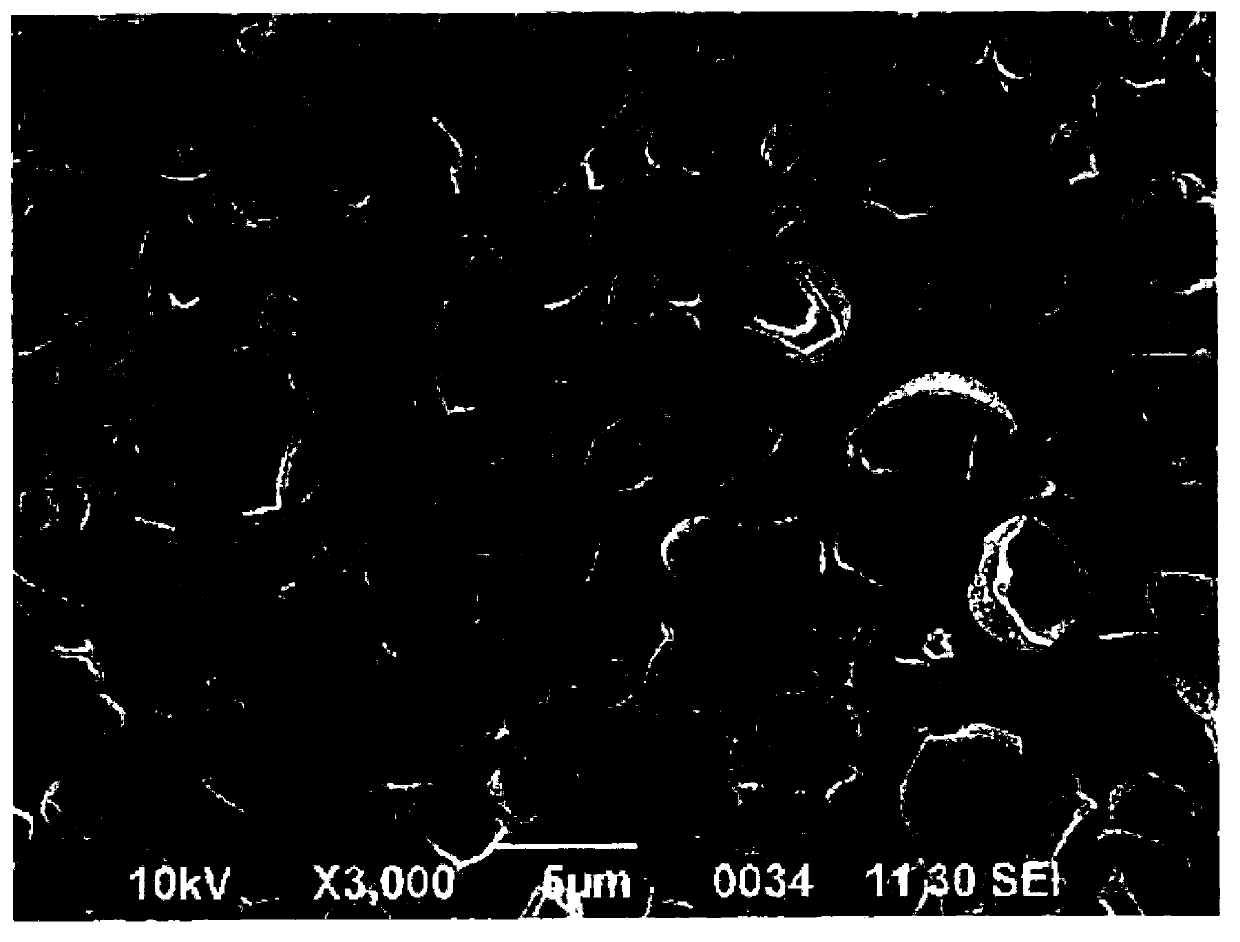

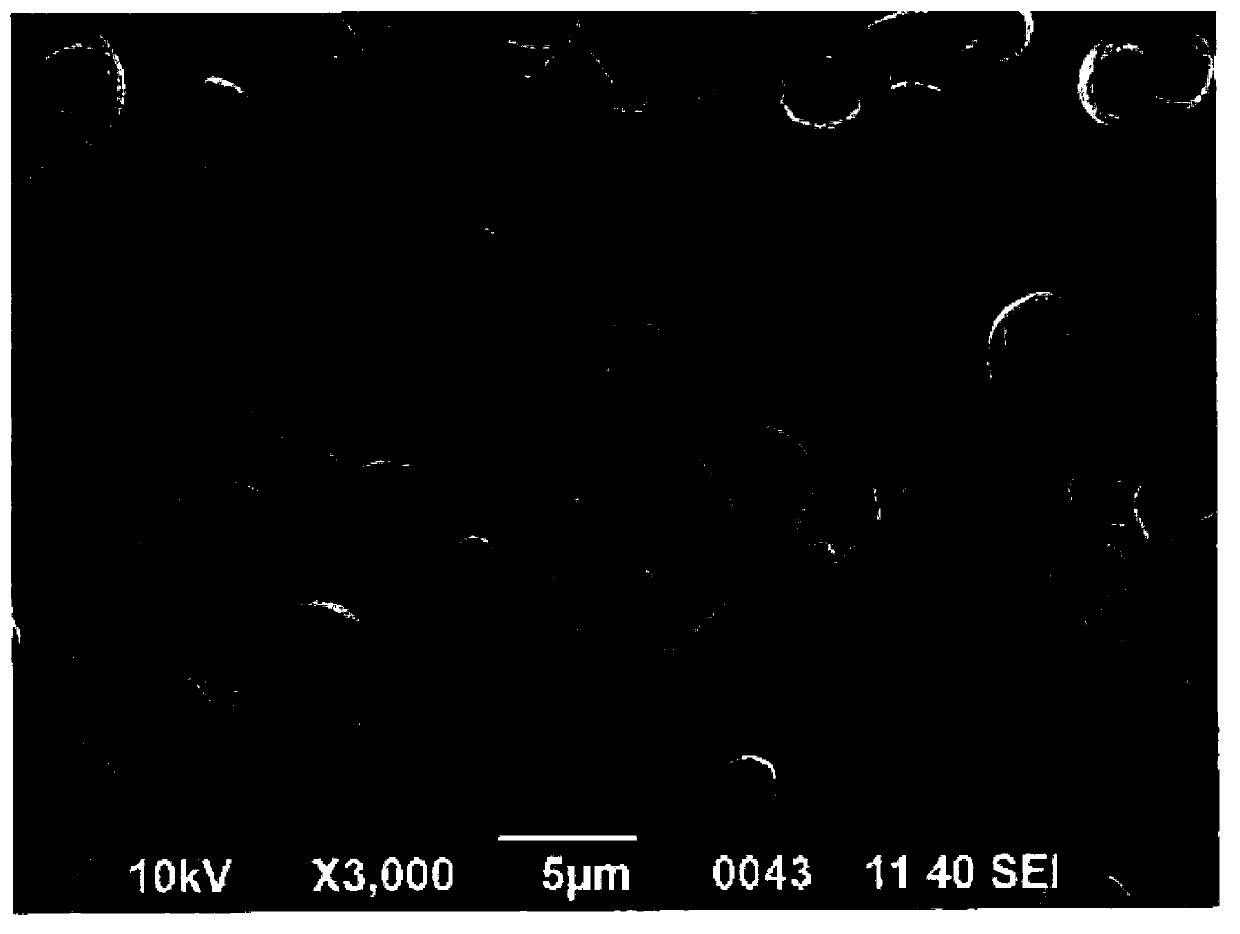

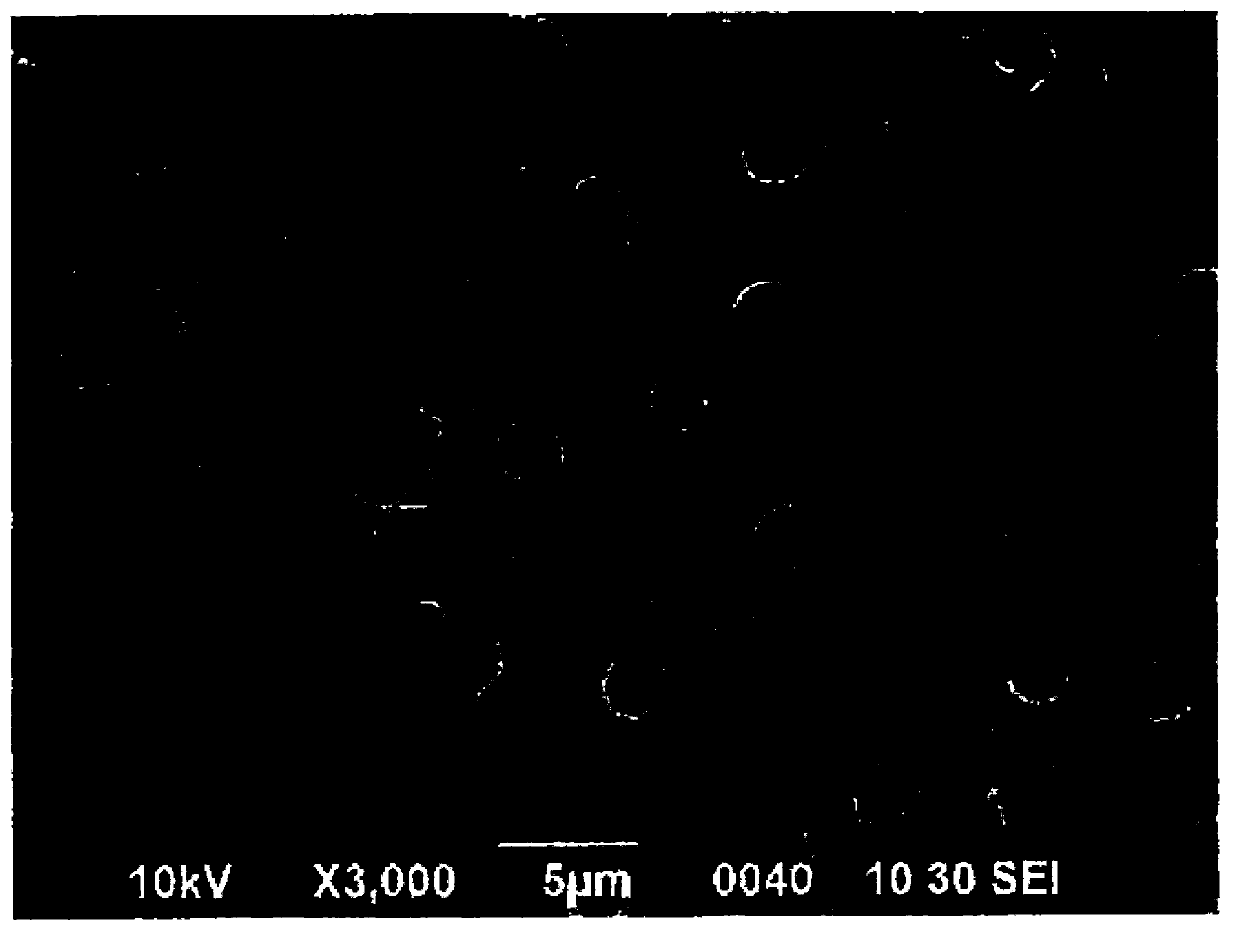

[0088] A magnified image obtained by photographing the obtained polymer particles with an electron microscope is shown in image 3 . by the image 3 It can be confirmed that the obtained polymer microparticles are different from the hollow polymer microparticles ( figure 1 ) compared with,...

Embodiment 3

[0093] The deionized water used when preparing the water phase was set to 586.2 g, and no diluent was used after emulsification dispersion and suspension polymerization. In addition, the same operation was carried out as in Example 2 to carry out the n-heptane contained in the microparticles. The gasification and removal, so as to obtain the particles made of hollow wet state.

[0094] It was confirmed that the number of depressed concave particles among the polymer particles decreased, and the number of hollow polymer particles with a high hollow ratio further increased, which was almost the same as in Example 2.

[0095] Table 1 shows the visual shape of the microparticles obtained in Example 3, and Table 2 shows the recording sensitivity of a thermosensitive recording medium using the microparticles as a heat insulating material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com