Method for preparing active-carbon-containing colloid gas foam for preventing gas emission in gob

A colloidal foam and gas gushing technology, which is applied in mining equipment, chemical instruments and methods, dust prevention, etc., can solve problems such as tight drainage, heavy construction work, and long drainage time, and achieve the purpose of suppressing the release of gas, The effect of delayed crosslinking and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

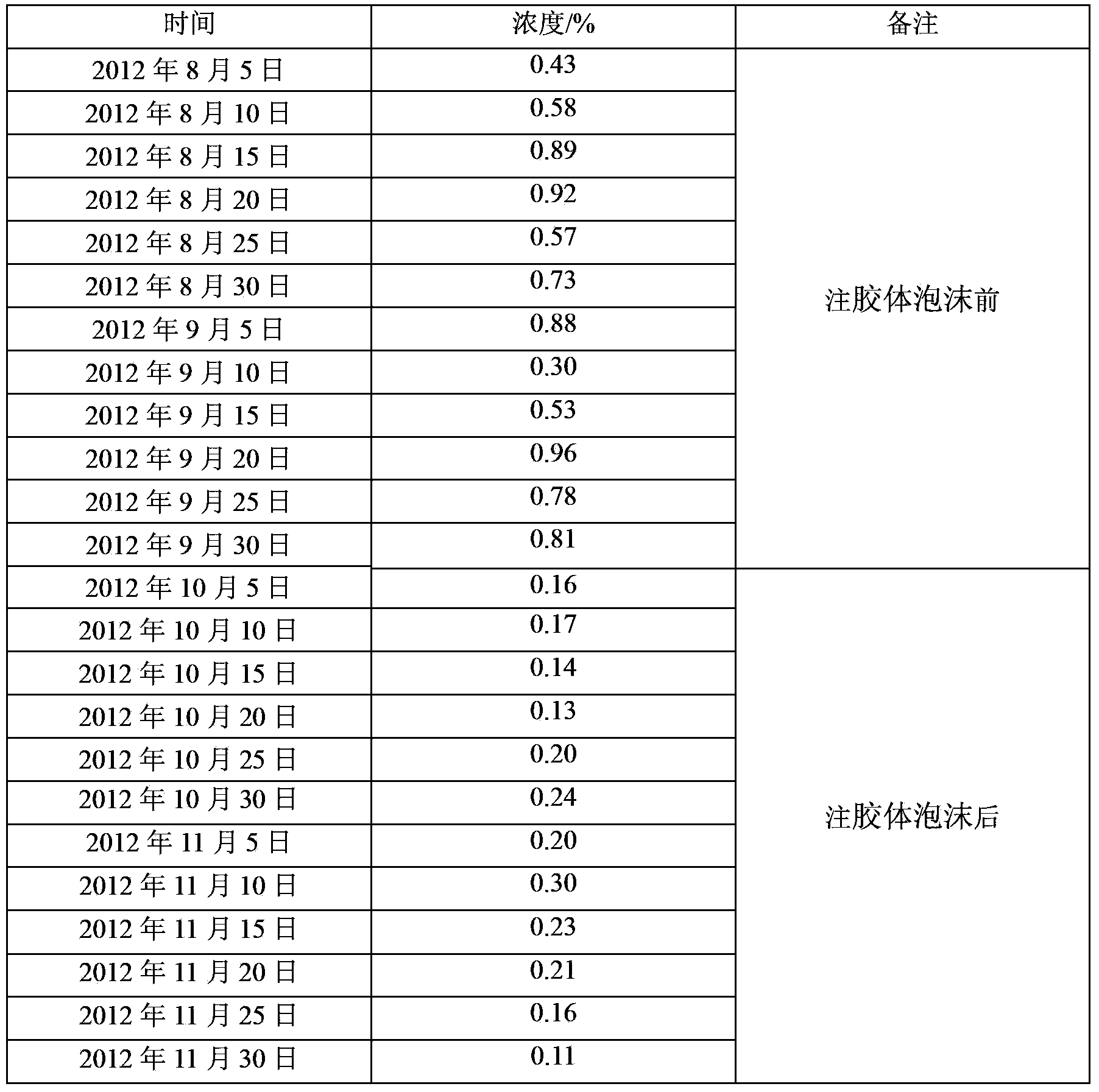

[0013] Example 1: The Buertai Coal Mine of Shendong Coal Company is a modern high-yield and high-efficiency mine, with a daily output of 15,000t at the working face. Due to the high mining intensity, the gas concentration in the upper corner is high, and it is difficult to effectively solve the gas in the upper corner by conventional methods. Using the method of colloidal foam with mining and injection, the solid phase is activated carbon with a diameter of less than 500 μm, the gas phase is compressed air generated by an air compressor, and the liquid phase is groundwater. Configure a thickening solution with a mass ratio of activated carbon, viscous agent and water of 1:0.03:10. After stirring evenly, add sodium silicate and dodecyldimethylbenzylammonium chloride to the thickening solution at the same time. Sodium silicate, dodecyl dimethyl benzyl ammonium chloride and thickened solution are prepared in a mass ratio of 3:4:1000, and are stirred to form a mixed solution. At t...

Embodiment 2

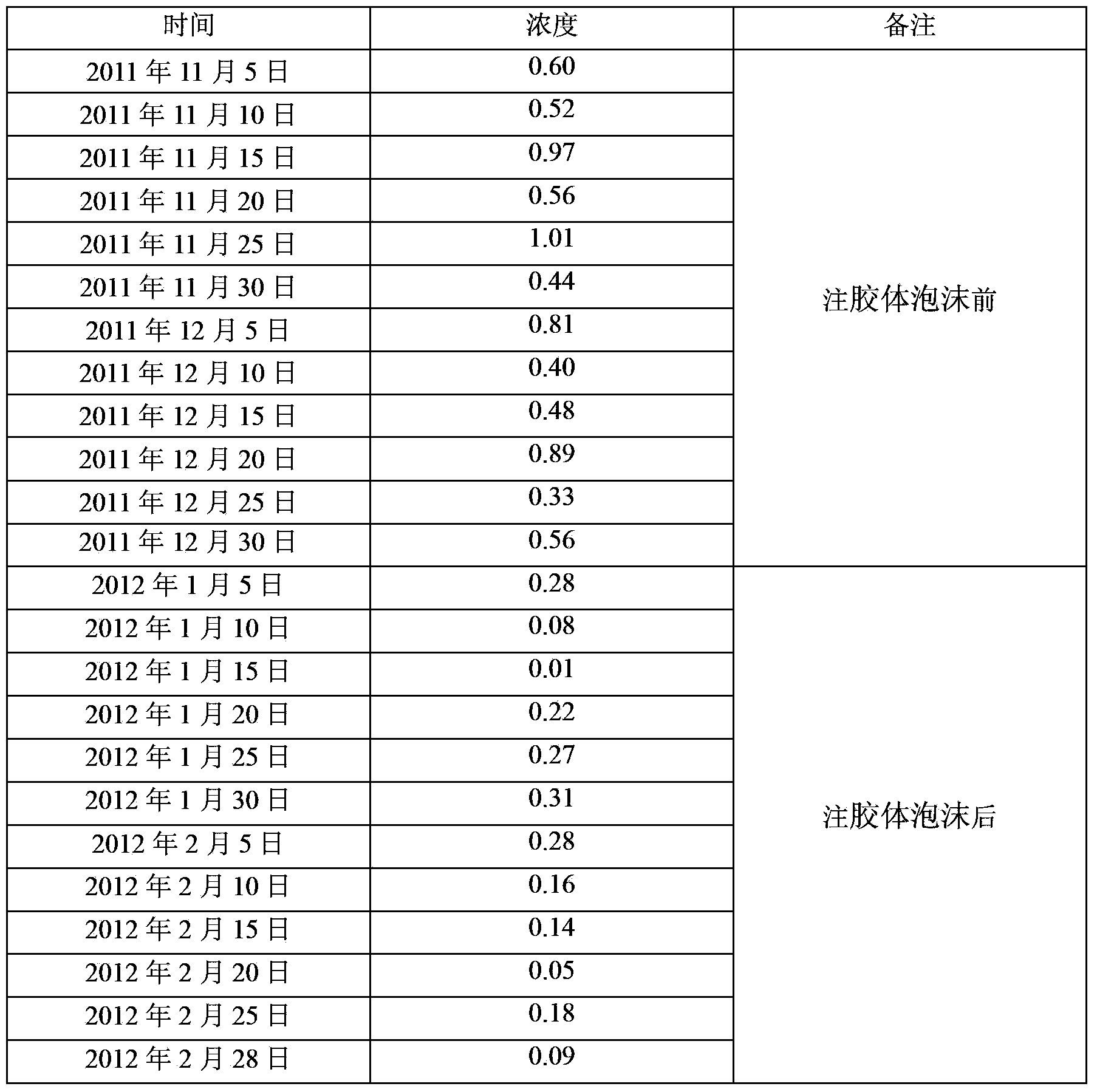

[0016] Example 2: SDIC Xinji No. 2 Mine is a high gas outburst mine. With the horizontal extension to the deep area of -750m, the gas gushing volume increases sharply, causing the gas to exceed the limit at the mining face. The method of colloidal foam with mining and injection is adopted, and activated carbon with a diameter of less than 500 μm is used as the solid phase, the compressed air generated by the air compressor is used as the gas phase, and the groundwater is used as the liquid phase. Prepare a thickening solution with a mass ratio of activated carbon, viscous agent and water of 1:0.03:10. After stirring evenly, add sodium silicate and dodecyldimethylbenzyl ammonium chloride to the thickening solution at the same time. Sodium silicate, dodecyl dimethyl benzyl ammonium chloride and thickened solution are prepared in a mass ratio of 3:4:1000, and stir to form a mixed solution. At this time, the flow rate of the mixed liquid is controlled to be 10-15m 3 / h, the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com