Surface modification method of polyacrylonitrile-based carbon fiber

A technology of polyacrylonitrile-based carbon fiber and polyacrylonitrile-based carbon, which is applied in the field of preparation of polyacrylonitrile-based carbon fiber, and can solve the problem that the interlayer shear strength and fiber tensile strength of carbon fiber composite materials cannot meet the requirements at the same time, and the process is complicated. problem, to achieve the effect of increased interlayer shear strength, simple process and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

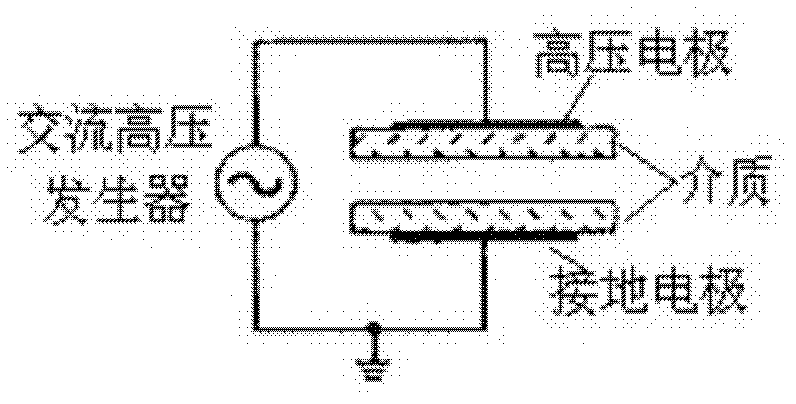

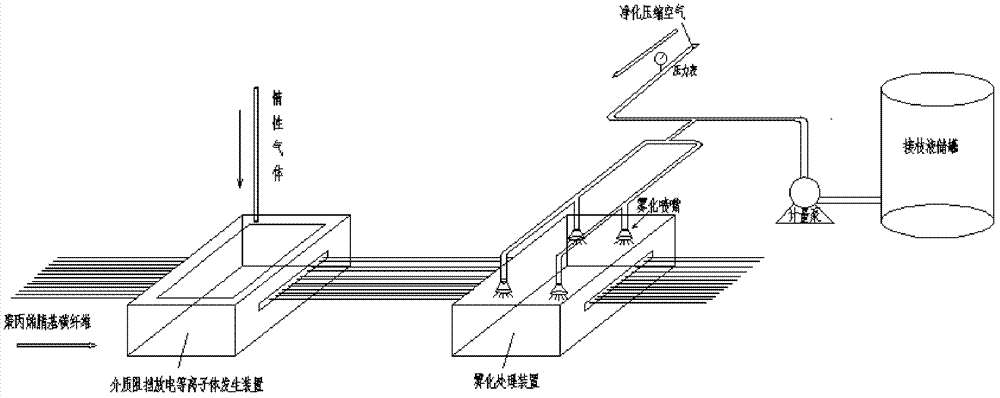

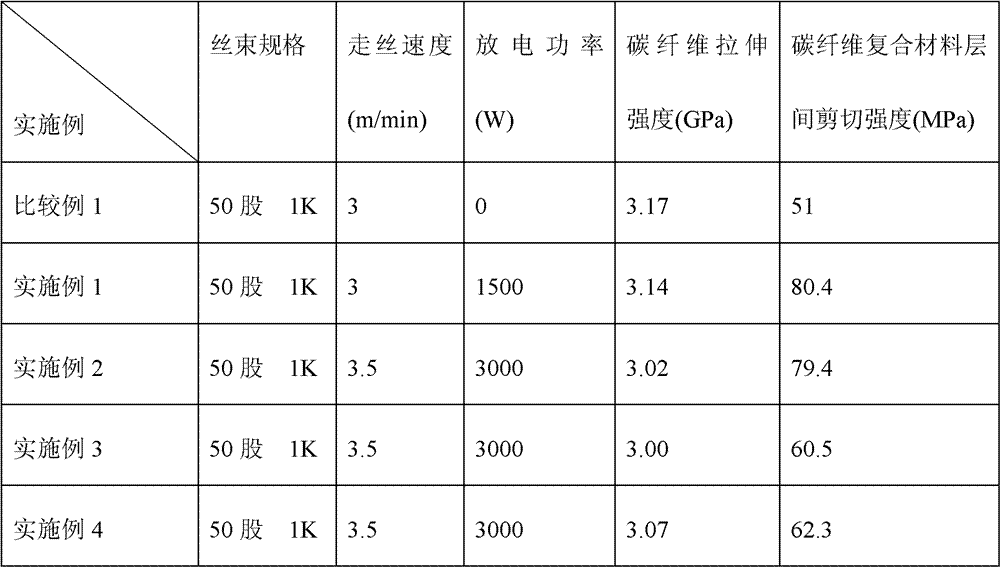

[0029] Control the wire-feeding speed of 50 strands of 1K carbon fiber to 3m / min, and use a dielectric barrier discharge plasma generator to conduct plasma treatment on the carbon fiber at the outlet of the high-temperature carbonization furnace under atmospheric pressure and argon gas. The discharge power of the dielectric barrier discharge plasma generating device is 1500W, and then the carbon fiber after the plasma treatment is atomized with a maleic anhydride solution. The mass percentage concentration of the maleic anhydride solution is 2%, and the pump supply rate is 0.05L / min. The pressure of purified compressed air is 0.4Mpa. After the surface modification of the polyacrylonitrile-based carbon fiber is completed, it is directly sent to the sizing, drying and winding process to obtain the finished carbon fiber, which is compounded with the resin matrix epoxy E-51 to form a carbon fiber composite material, and the interlayer shear is measured. strength value.

Embodiment 2

[0031] Control the wire-feeding speed of 50 strands of 1K carbon fiber to 3.5m / min, and use a dielectric barrier discharge plasma generator to conduct plasma treatment on the carbon fiber at the outlet of the high-temperature carbonization furnace under atmospheric pressure and argon gas. The discharge power of the dielectric barrier discharge plasma generating device is 3000W, and then the carbon fiber after plasma treatment is atomized with maleic anhydride solution. The mass percentage concentration of maleic anhydride solution is 2.5%, and the pump supply rate is 0.1L / min. The pressure of purified compressed air is 0.5Mpa. After the surface modification of the polyacrylonitrile-based carbon fiber is completed, it is directly sent to the sizing, drying and winding process to obtain the finished carbon fiber, which is compounded with the resin matrix epoxy E-51 to form a carbon fiber composite material, and the interlayer shear is measured. strength value.

Embodiment 3

[0033] Control the wire-feeding speed of 50 strands of 1K carbon fiber to 3.5m / min, and use a dielectric barrier discharge plasma generator to conduct plasma treatment on the carbon fiber at the outlet of the high-temperature carbonization furnace under atmospheric pressure and argon gas. The discharge power of the dielectric barrier discharge plasma generating device is 3000W, and then the carbon fiber after the plasma treatment is subjected to atomization treatment of a mixed solution of methyl acrylate and acrylamide. The mass percentage concentration of the mixed solution is 2.5%, methyl acrylate: propylene Amide=1:1 (molar ratio), the pump supply rate is 0.1L / min, and the pressure of purified compressed air is 0.5Mpa. After the surface modification of polyacrylonitrile-based carbon fiber is completed, it is directly sent to the sizing, drying and winding process to obtain the finished carbon fiber, which is compounded with resin matrix epoxy E-51 to form a carbon fiber com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge power | aaaaa | aaaaa |

| Discharge power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com