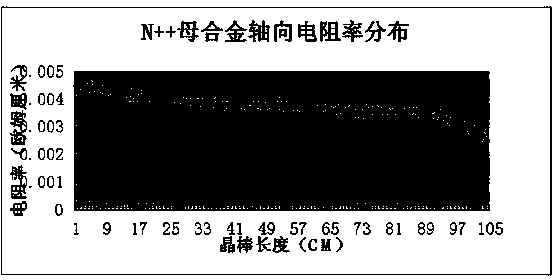

Preparation process of N-type heavily-doped phosphorus master alloy silicon rod

A preparation process and master alloy technology, applied in the directions of diffusion/doping, crystal growth, post-processing, etc., can solve problems such as influence, and achieve the effect of ensuring safety and uniform resistivity of crystal rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] 1. Choose a Tianlong 85 single crystal furnace, use 20" graphite heat field and 20" quartz crucible, charge 70 kg polycrystalline silicon, heat and melt;

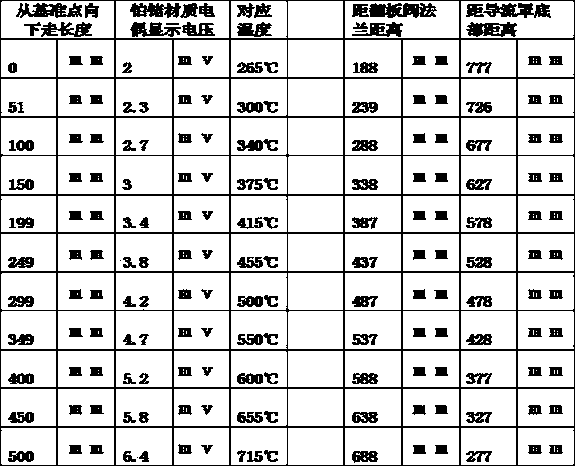

[0033] 2. Put 520 grams of "N" high-purity red phosphorus into the quartz dopant (designed and processed according to the longitudinal temperature gradient test data of the dynamic thermal field of the single crystal furnace in the previous stage);

[0034] 3. Install the adaptable dopant on the seed crystal bayonet, lift it into the auxiliary chamber to guide the air, and then open the flip valve to lower the quartz dopant to the tested 390mm position, so that its sublimation can be automatically introduced into the silicon melt , and pull the crystal under the conditions of ingot speed--12 rpm, crucible speed--8 rpm, ingot head pulling speed--1.1mm / min, furnace pressure--2000-2500Pa;

[0035] 4. The drawn ingots can be cut into 2 cm thick round cakes, classified according to the resistivity, and the difference is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com