Low temperature resistant winter epoxy coal tar pitch coating

A technology of epoxy coal tar and asphalt coatings, which is applied in the direction of asphalt coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of affecting the tensile strength and deformation ability of coatings, the decline of deformation ability, and the reduction of toughness, and achieve excellent results. Film performance and anti-corrosion performance, long protection time, effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

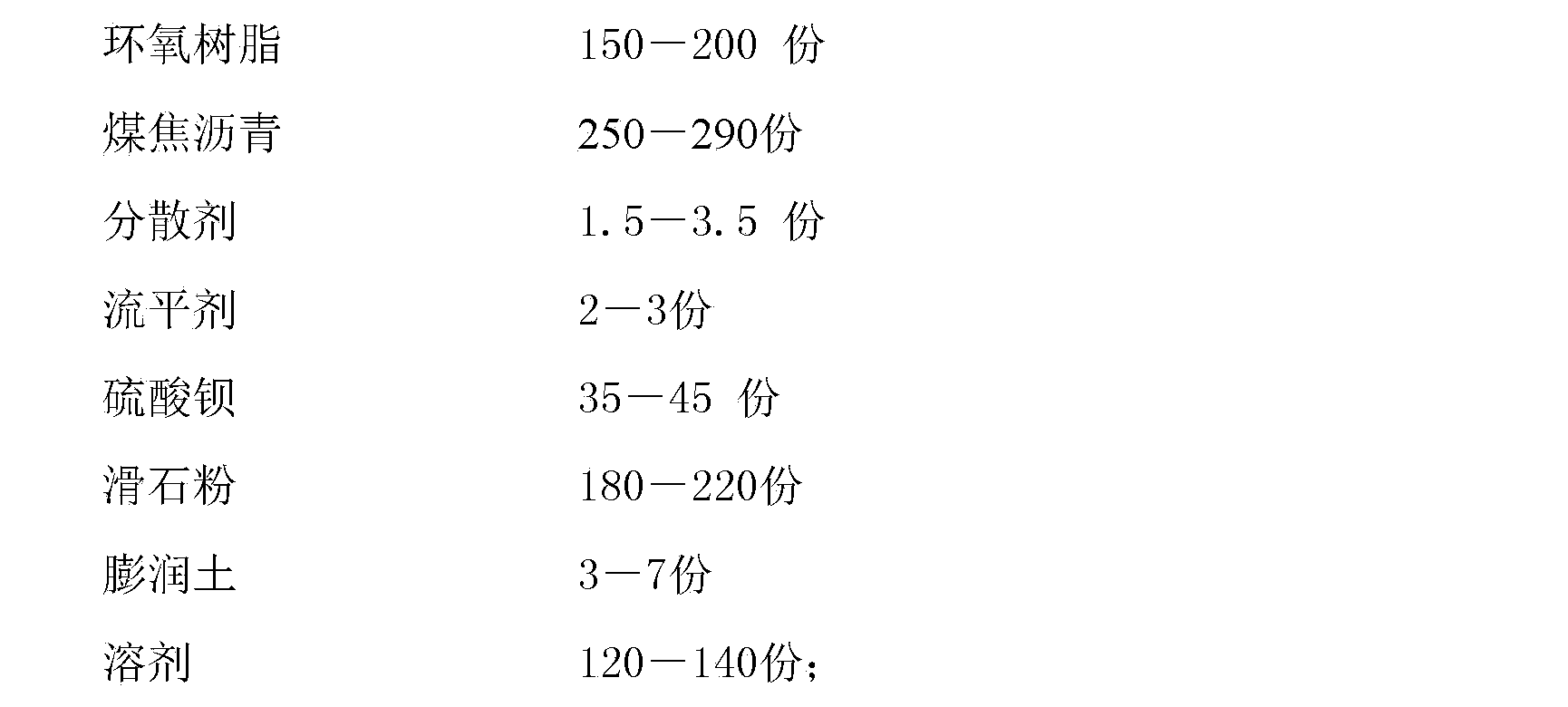

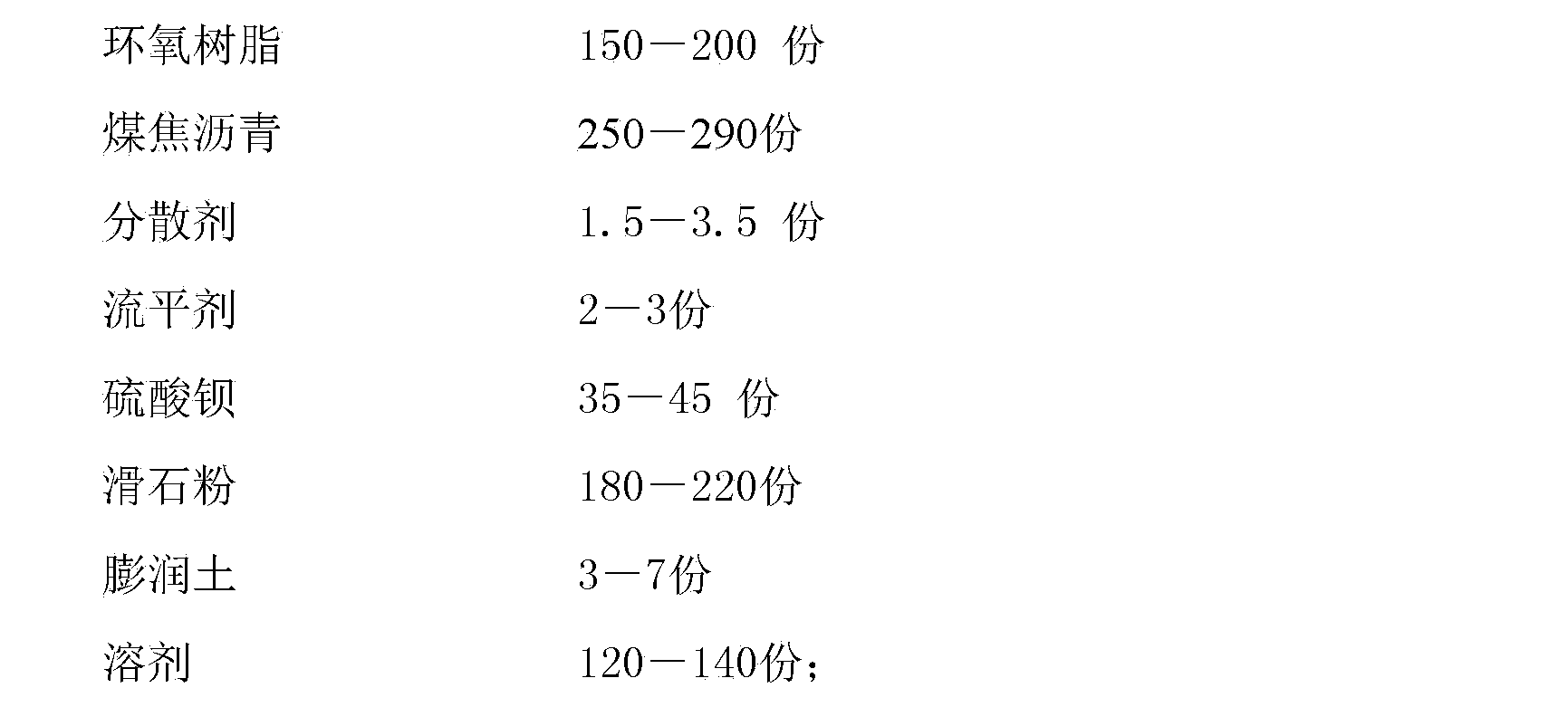

Method used

Image

Examples

Embodiment 1

[0018] Preparation of component A: 150 parts of epoxy resin, 1.5 parts of stearate, 2 parts of silicone oil, 35 parts of barium sulfate, 200 parts of talcum powder, 7 parts of bentonite, 80 parts of xylene, 39 parts of butanol, 1 part of alcohol One part was placed in a reaction kettle and heated to 85°C for 30 minutes. After mixing evenly, 250 parts of coal tar pitch was added and stirred for 30 minutes. The heat preservation treatment was performed for two hours to obtain Component A;

[0019] Preparation of component B: Mix 60 parts of polyamide and 70 parts of xylene to obtain component B;

[0020] The previously prepared component A and component B are stirred and mixed, and then filtered to obtain the epoxy coal tar pitch coating.

Embodiment 2

[0022] Preparation of component A: 170 parts of epoxy resin, 2 parts of polyethylene wax, 2.5 parts of polydimethylsiloxane, 40 parts of barium sulfate, 180 parts of talcum powder, 3 parts of bentonite, 85 parts of xylene, butanol 45 parts and 1140 parts of alcohol were placed in a reaction kettle and heated to 85°C, stirred for 30 minutes, after mixing evenly, 260 parts of coal tar pitch were added and stirred for 30 minutes, and heat-preserved for two hours to obtain component A;

[0023] Preparation of component B: Mix 70 parts of polyamide and 70 parts of xylene to obtain component B;

[0024] The previously prepared component A and component B are stirred and mixed, and then filtered to obtain the epoxy coal tar pitch coating.

Embodiment 3

[0026] Preparation of component A: 200 parts of epoxy resin, 3 parts of ethylene bisstearamide, silicone oil, polydimethylsiloxane, 3 parts of polyether polyester modified organosiloxane, 45 parts of barium sulfate , 220 parts of talcum powder, 7 parts of bentonite, 80 parts of xylene, 45 parts of butanol, and 5 parts of alcohol were placed in the reaction kettle and heated to 85 ° C for 30 minutes. After mixing evenly, 290 parts of coal tar pitch were added and stirred for 30 minutes. , heat preservation treatment for two hours to obtain component A;

[0027] Preparation of component B: Mix 70 parts of polyamide and 75 parts of xylene to obtain component B;

[0028] The previously prepared component A and component B are stirred and mixed, and then filtered to obtain the epoxy coal tar pitch coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com