Silk fibroin nanofiber membrane and preparation method thereof

A technology of nanofiber membrane and silk fibroin, applied in the field of silk fibroin nanofiber membrane and its preparation, can solve the problems of poor mechanical properties of silk fibroin nanofiber membrane and damage to nanostructure, etc. Fast, excellent biocompatibility results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Natural mulberry silk was boiled with 0.5wt% sodium carbonate solution for 30 minutes, degummed, and degummed mulberry silk was obtained after repeating 3 times;

[0038] (2) Put the degummed mulberry silk in 95wt% formic acid containing 5wt% lithium bromide at a concentration of 20wt%, stir and dissolve at room temperature for 2 hours, then pour it into a polyethylene plate to dry to form a film;

[0039] (3) Soak the membrane in step (2) in running water for 3 hours to remove lithium bromide, and then dry it in a vacuum oven at 40°C for 24 hours;

[0040] (4) dissolving the membrane in step (3) in 80wt% formic acid to prepare 5wt% and 8wt% spinning solutions, and then electrospinning to obtain nanofiber membranes;

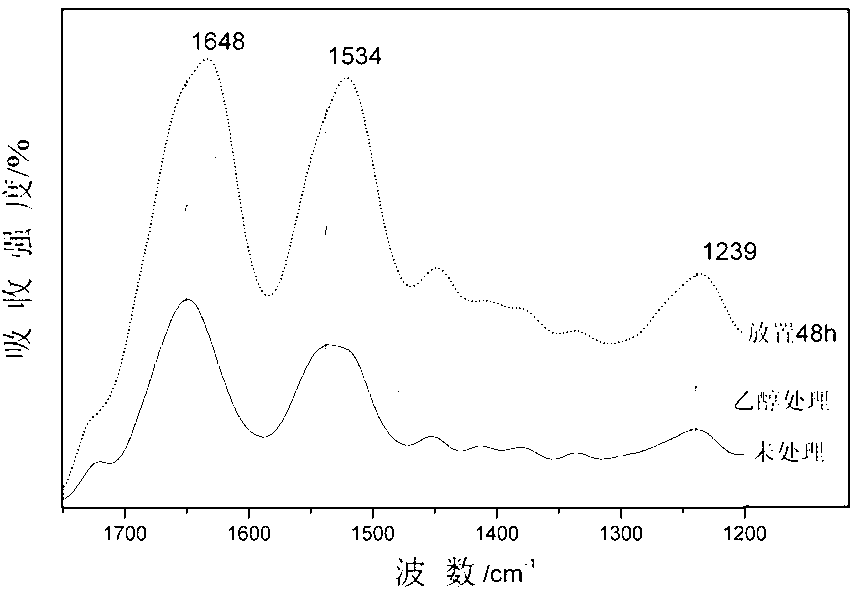

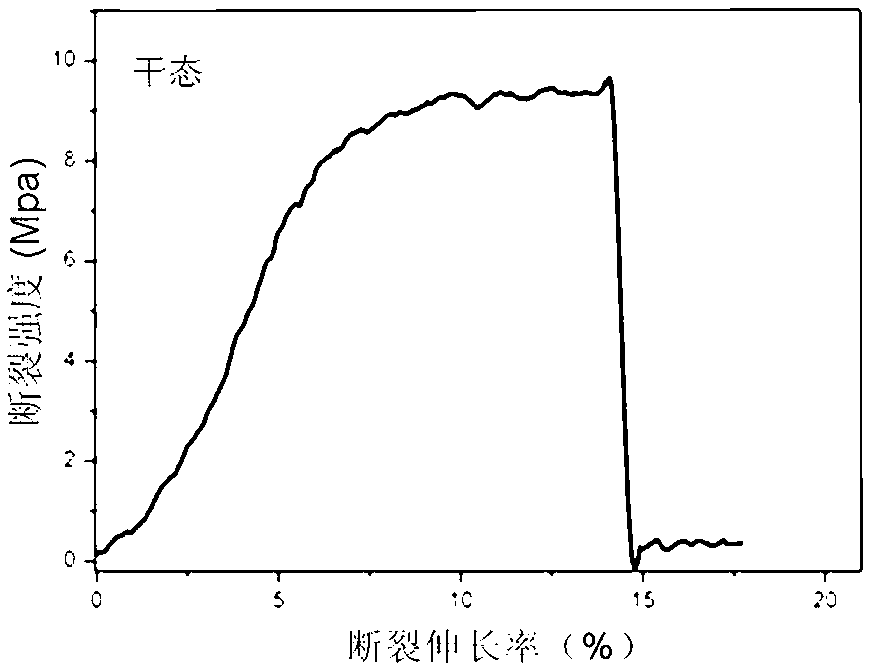

[0041] (5) The nanofiber membrane obtained in step (4) is left for 48 hours, or directly soaked in ethanol solution for 30 minutes to obtain a silk fibroin nanofiber membrane.

[0042] attached figure 1 It is the scanning electron micrograph of the a...

Embodiment 2

[0044] (1) Natural mulberry silk was degummed by boiling 0.5wt% sodium carbonate solution for 30 minutes, and degummed mulberry silk was obtained after repeating 3 times;

[0045](2) Put degummed mulberry silk at a concentration of 10wt% in 50wt% mixed acid containing 5wt% lithium thiocyanate (phosphoric acid: formic acid = 1:4, mass ratio), stir and dissolve at 60°C for 1 hour, and then pour it into poly Dried into a film on a vinyl plate;

[0046] (3) Soak the membrane in step (2) in running water for 3 hours to remove salt and residual acid, and then dry it in a vacuum oven at 60°C for 20 hours;

[0047] (4) Dissolve the film in step (3) in hexafluoroisopropanol to prepare a 10wt% solution, and dissolve chitosan in hexafluoroisopropanol to prepare a 10wt% solution, and then mix the two solutions at a ratio of 1:1 Volume blending preparation concentration is 10wt%, silk fibroin and chitosan 1:1 (mass ratio) blended spinning solution;

[0048] (5) Process the blended spinni...

Embodiment 3

[0051] (1) Natural mulberry silk was degummed by boiling 0.5wt% sodium carbonate solution for 30 minutes, and degummed mulberry silk was obtained after repeating 3 times;

[0052] (2) Put the degummed mulberry silk in 80wt% formic acid containing 10wt% zinc chloride at a concentration of 10wt%, stir and dissolve at room temperature for 2 hours, and then pour it into a polyethylene plate to dry to form a film;

[0053] (3) Soak the silk fibroin film in step (2) in flowing water for 3 hours to remove zinc chloride and residual acid, and then dry it in a vacuum drying oven at 80°C for 15 hours;

[0054] (4) dissolving the membrane in step (3) in 80wt% formic acid to prepare an 8wt% spinning solution, and then electrospinning to obtain a silk fibroin nanofiber membrane;

[0055] (5) The silk fibroin nanofiber membrane obtained in step (4) was treated in 80 wt% methanol for 30 minutes to realize the transformation of the silk fibroin structure from amorphous to β-sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com