Oxygen electrode composite catalyst used for lithium-air batteries and preparation method of the oxygen electrode composite catalyst

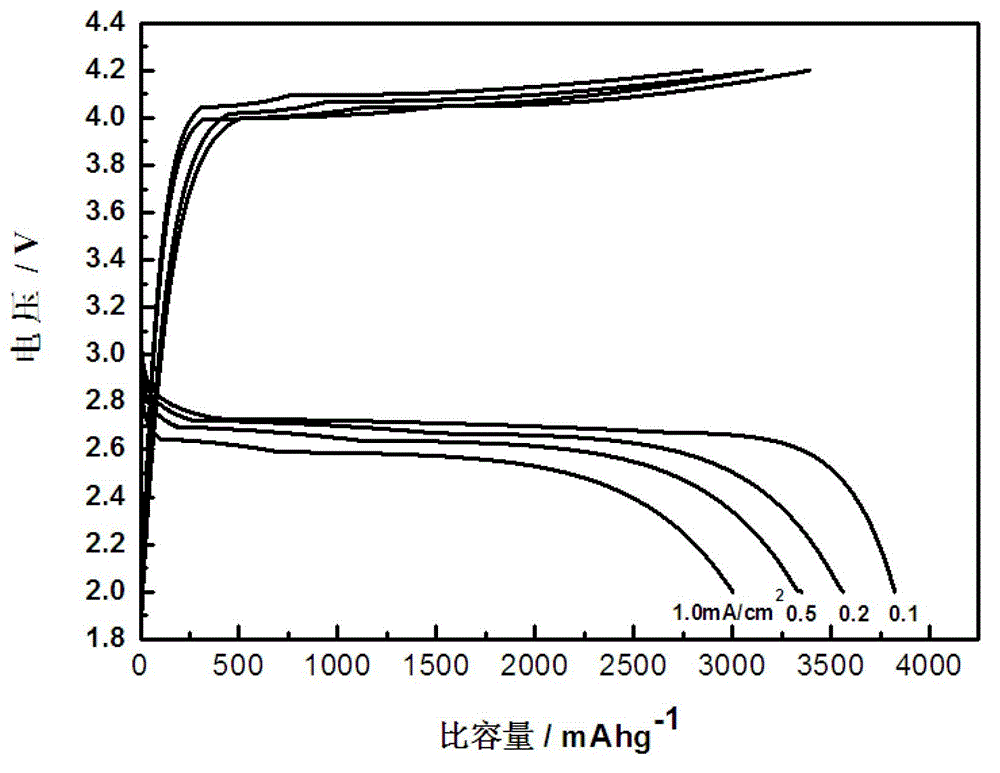

A composite catalyst, lithium-air battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increasing the electrochemical polarization of lithium-air batteries, failing to form a three-phase reaction interface, hindering oxygen diffusion, etc. Charge-discharge capacity and rate capability, the effect of promoting electrochemical reduction reaction and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, add 10ml of N'-dimethylformamide (DMF) solvent to a 20ml sealed bottle, add 0.5603g of manganese acetate tetrahydrate and 0.05325g of nickel acetate tetrahydrate with stirring, and when it is completely dissolved, continue to stir and slowly Slowly add 1.0g of high molecular polymer polyacrylonitrile (PAN), continue to stir and start to slowly heat to 50°C, stir for 8h at a constant temperature of 50°C to form a uniform electrostatic spinning solution with a certain viscosity; leave the static at room temperature Spin the solution for 4 hours until the bubbles in the solution disappear completely, electrospin the electrostatic spinning solution that has been left to remove the bubbles to prepare high molecular polymer nanofibers with a diameter of 600 nm; the above-mentioned high molecular polymer obtained by the electrostatic spinning technology After drying on the nanofiber at 80℃ for 12h in a vacuum environment to remove the residual solvent in the...

example 2

[0034] At room temperature, add 8ml of N'-dimethylformamide (DMF) solvent and 2ml of acetone to a 20ml sealed bottle in turn, add 0.6239g of manganese acetate tetrahydrate under stirring, and when it is completely dissolved, continue to stir and add gradually 0.9g high molecular polymer polyacrylonitrile (PAN) and 0.1g polyethylene oxide (PEO), continue to stir and start to slowly heat to 50°C, at a constant temperature of 50°C, stir for 8h to form a uniform electrostatic spinning with a certain viscosity Solution; The electrostatic spinning solution is allowed to stand at room temperature for 3 hours until the bubbles in the solution disappear completely, and the electrostatic spinning solution that has been statically de-bubbled is subjected to electrostatic spinning to prepare high molecular polymer nanofibers with a diameter of 300 nm; the above adopts electrostatic spinning The high molecular polymer nanofibers obtained by silk technology were dried at 80℃ for 12 hours in a...

example 3

[0037] At room temperature, add 8ml of N'-dimethylformamide (DMF) solvent and 2ml of absolute ethanol to a 20ml sealed bottle in turn, add 0.6227g of cobalt acetate tetrahydrate with stirring, and when it is completely dissolved, continue to stir and sequentially Slowly add 0.8g of high molecular polymer polyacrylonitrile (PAN) and 0.1g of polyvinylpyrrolidone (PVP), continue to stir and start to slowly heat to 50°C, stir for 8h at a constant temperature of 50°C to form a uniform viscosity Electrospinning solution; the electrospinning solution is allowed to stand at room temperature for 5 hours until the bubbles in the solution disappear completely, and the electrostatic spinning solution that has been left to remove the bubbles is subjected to electrospinning to prepare high molecular polymer nanofibers with a diameter of 500 nm; The high molecular polymer nanofibers obtained by electrospinning technology were dried for 12 hours in a vacuum environment at 80℃ to remove the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com